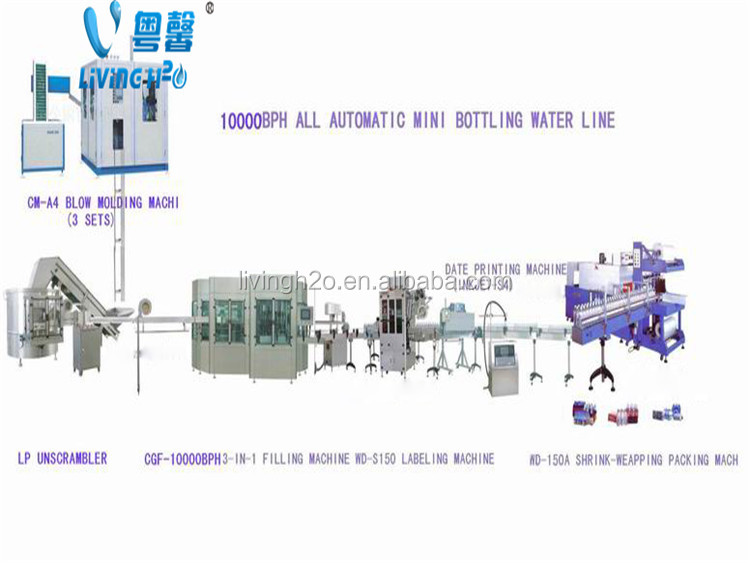

Fruit Juice Mango Beverage Processing Line Equipment Machinery

-

Supplier: Jiangmen Living Drinking Water Equipment Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Vivian Long -

Price: $12500.00 /set -

Min. Order: 1 set

Product details

| Name: | Fruit juice mango beverage processing line | Dimensions (L*W*H): | 2350*1610*2250mm |

| Production capacity: | 1500-24000BPH | Packaging Preview: | |

| Filling liquid: | juice | Bottle size: | 100-2000ml |

| Mechanical Capability: | 1500-24000BPH | payment terms: | L/C,Western Union,T/T,MoneyGram |

| type of packaging: | bottle, bag, can, capsule, carton, case, pouch | Health status: | new |

| Materials used for packaging: | PET, glass | Video external inspection: | if |

| Warranty: | 2 years | Applicable industries: | Food and Beverage Stores, Manufacturing Plants, Restaurants, Food and Beverage Plants, Farms |

| port: | Jiangmen, Shenzhen, Guangzhou, Shanghai | Filling Type: | hot filling |

| Supply capacity: | 10 sets per month | year: | 2022 |

| Core Components Warranty: | 2 years | Auto grade: | Fully automatic |

| Weight (kg): | 4500 | Marketing Type: | Hot Sale 2022 |

| Showroom location: | Italy, Brazil, India, Thailand, Chile, United Arab Emirates, Algeria, Kazakhstan, Japan, Canada, Ukraine | place of origin; place of origin: | Guangdong, China |

| Drive Type: | Electric, motor drive | Voltage: | 220V/380V |

| Core components: | Motors, Pressure Vessels, Pumps, PLCs, Gears, Bearings, Gearboxes, Engines | Packaging Details: | Plywood/Wooden Box |

| Main selling point: | high accuracy | application: | Beverage Products |

| process: | filling | Mechanical test report: | if |

| brand: | living water |

Product Description

application:

This bottled water filling machine is used to produce non-carbonated beverages of mineral and purified water in PET bottles. Cleaning, filling and capping are integrated in one machine. The whole machine has scientific and reasonable design, beautiful appearance, complete functions, convenient operation and maintenance, and high degree of automation. The design uses the most advanced technology from Italy and Germany. Filled with gravity fixed liquid level. The filling speed is fast, the liquid volume control is accurate, and the dripping is avoided. Use spring cramps during bottle washing. Empty bottles can be turned 180° along the conveying track. Bottle washing efficiency is high. Magnetic torque is used for capping. The capping force can be adjusted steplessly. The power of capping can also be fixed without damaging the cap, and the capping is reliable. The whole machine is controlled by PLC, and the touch screen is a man-machine interface. The amount of beverage in the tank can be automatically controlled. No bottle filling stops automatically. The machine can automatically stop when the bottle is mistakenly narrow or has no cap. The frequency is adjusted to stepless speed regulation. production capacity can

Digital display, easy to adjust.

This bottled water filling machine is used to produce non-carbonated beverages of mineral and purified water in PET bottles. Cleaning, filling and capping are integrated in one machine. The whole machine has scientific and reasonable design, beautiful appearance, complete functions, convenient operation and maintenance, and high degree of automation. The design uses the most advanced technology from Italy and Germany. Filled with gravity fixed liquid level. The filling speed is fast, the liquid volume control is accurate, and the dripping is avoided. Use spring cramps during bottle washing. Empty bottles can be turned 180° along the conveying track. Bottle washing efficiency is high. Magnetic torque is used for capping. The capping force can be adjusted steplessly. The power of capping can also be fixed without damaging the cap, and the capping is reliable. The whole machine is controlled by PLC, and the touch screen is a man-machine interface. The amount of beverage in the tank can be automatically controlled. No bottle filling stops automatically. The machine can automatically stop when the bottle is mistakenly narrow or has no cap. The frequency is adjusted to stepless speed regulation. production capacity can

Digital display, easy to adjust.

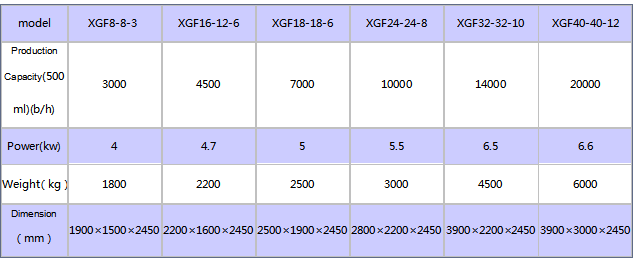

Product parameters

VIEW MORE

You may like

-

1 inch aerosol filling and capping machine with valve manual aerosol can sealing machine

-

Fully Automatic Blister Board Candy Packaging DPP-260 Alu ALu Blister Packaging Machine For Tablet Packaging

-

1-100ml small liquid, liquid detection, automatic essential oil filling and capping machine

-

Automatic Syrup Bottle Filling Labeling Machine/Pharmaceutical Syrup Filling Product Line

-

Automatic Desktop Perfume Vial Filling Machine Cosmetic Cream Jar Liquid Filling Capping Labeling Machine

-

1 Inch Manual Aerosol Valve Crimping Machine

-

desktop filling and capping machine, small semen filling machine

-

A03 Manual Filling Machine Manual Nail Polish Shampoo Filling Machine 5~50ml for Cream Shampoo Cosmetics Liquid Paste Oil Filling Machine

-

desktop filling and capping machine, small semen filling machine

Other Products

-

$1600.00 / set

$1600.00 / set -

$5300.00 / set

$5300.00 / set -

$6300.00 / set

$6300.00 / set