Forced Circulation MVR Evaporator System for Thermal and Vacuum Evaporation and Desalination of Chemical Crystallization Wastewater

-

Supplier: Shandong Mingtian Machinery Group Joint Stock Co., Ltd. -

Region: Shandong, China -

Contact: Mr Luis Wang -

Price: $785600.00 /set -

Min. Order: 1 set

| Video external inspection: | if | application: | Chemical wastewater desalination |

| Core components: | PLC, motor, pressure vessel, pump | Vacuum degree: | 0.098Mpa |

| Mechanical test report: | if | Applicable industries: | Food and Beverage Plants, Energy and Mining, Chemical Plants, Coking Plants, Power Plants, Desalination, Sodium Chloride Plants, Sodium Sulfur Plants |

| Evaporation Type: | vacuum evaporation | Marketing Type: | Hot Products of 2019 |

| brand: | Shanko | Packaging Details: | Standard export wood/steel box or customer request forced circulation MVR evaporator system for thermal and vacuum evaporation and crystallization chemical wastewater desalination |

| Material: | 316L/2205/304 | Showroom location: | Vietnam, India, Mexico |

| Advantage: | steam savings | strength: | 15KW/37KW/45KW/90KW/110KW |

| Supply capacity: | 500 sets/year MVR evaporator | place of origin; place of origin: | Shandong China |

| Health status: | new | product name: | MVR evaporator |

| Main selling point: | energy saving | Evaporating flask: | custom made |

| Evaporation: | 0.1 to 800 tons/hour | Warranty: | 1 year |

| port: | Qingdao; Tianjin; Shanghai | Packaging Preview: | |

| process: | vacuum distillation | Core Components Warranty: | 1 year |

| Evaporation temperature range: | 50℃-95℃ | Voltage: | 220/380/415/440/480V |

| Energy source: | electrical | weight: | 26000kg |

| payment terms: | letter of credit, wire transfer |

Forced Circulation MVR Evaporator System for Thermal and Vacuum Evaporation and Crystallization Chemical Wastewater Desalination

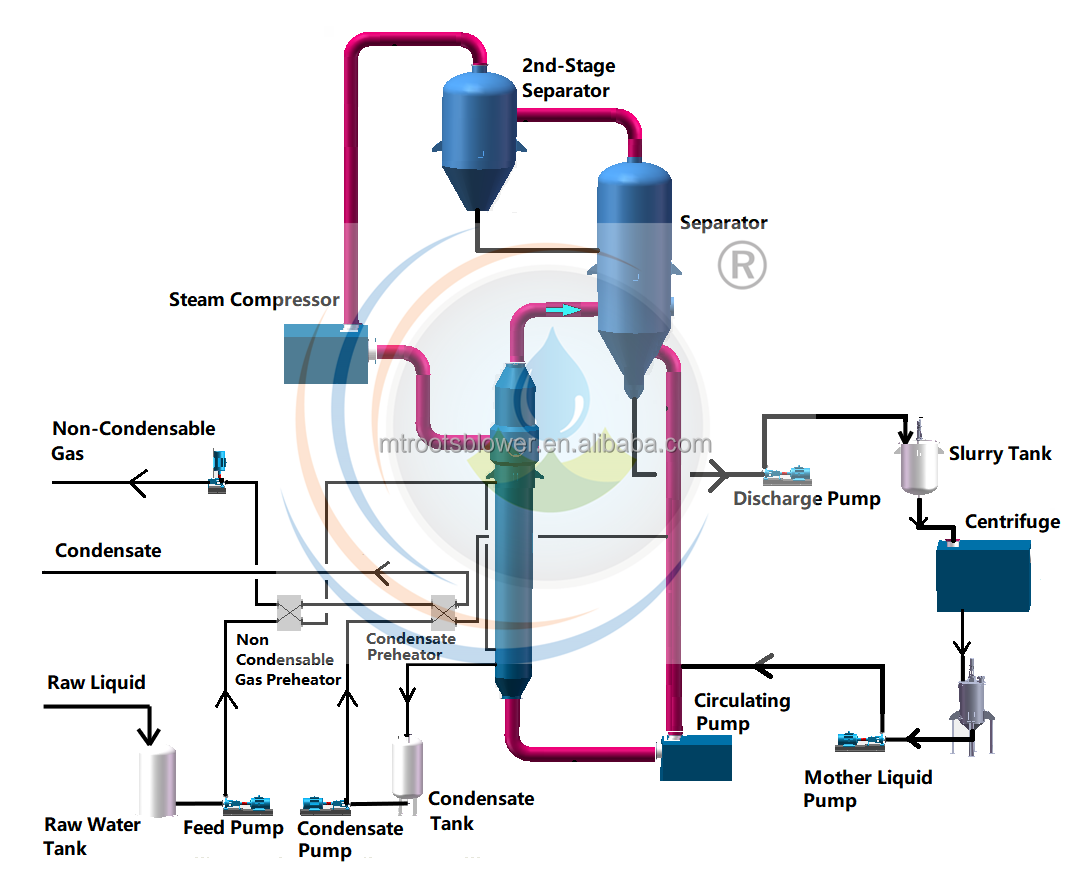

main principle

The MVR evaporator utilizes the secondary steam generated in the evaporator to be mechanically compressed by the compressor, pressurized and heated, and then condensed by the heat exchanger to make full use of the latent heat of the steam, except for startup. Running upward, the whole evaporation process does not need a single steam in theory, so that the originally discarded steam can be fully utilized, latent heat is recovered, and thermal efficiency is improved. The economy is equivalent to 30-effect multi-effect evaporation.

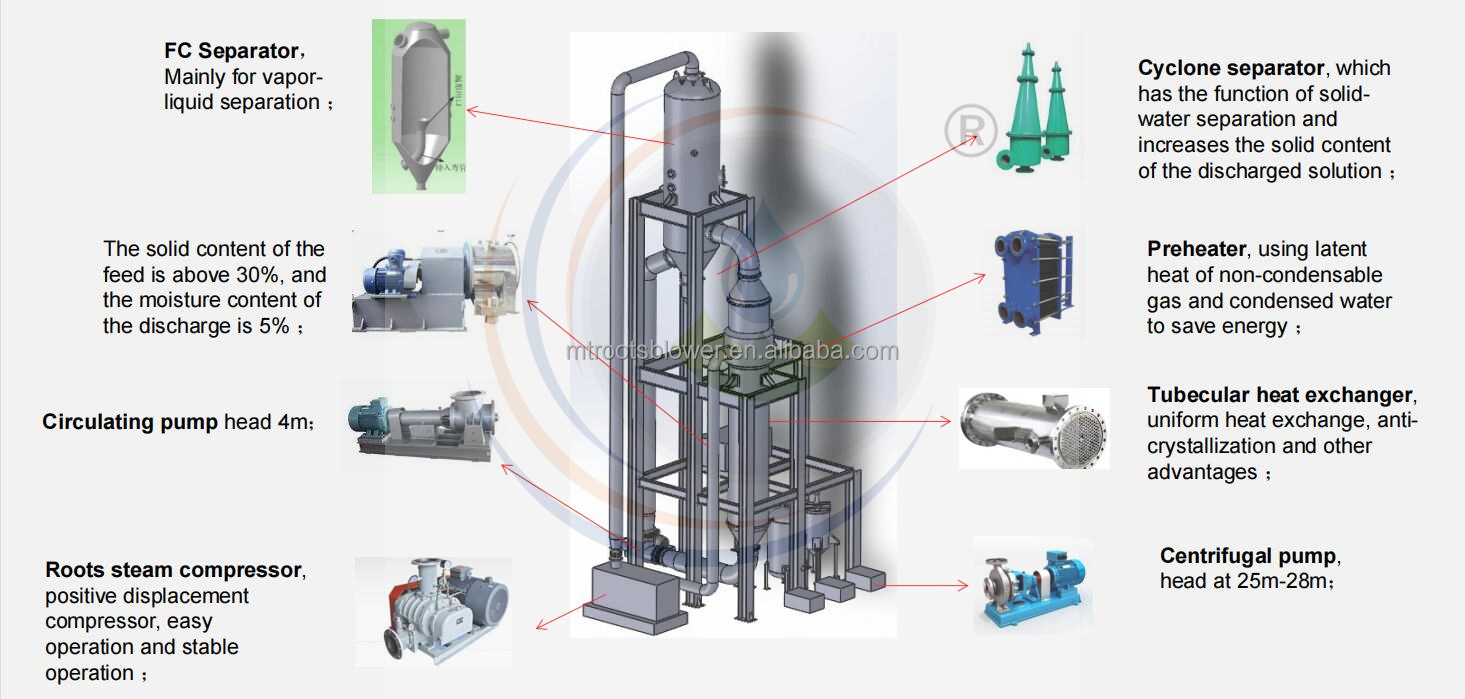

System composition

The heating system consists of heaters, separators, compressors, vacuum pumps, circulating pumps, operating platforms, electrical instrumentation control cabinets, valves, and piping systems.

Main Features of MVR Evaporator System

1) MVR energy-saving evaporator technology is currently the most advanced evaporator technology in the world, requiring only a very small amount of raw steam (a small amount of steam is required when starting up, and almost no steam is needed during normal operation, which greatly reduces the company's operating costs and reduces environmental pollution.

2) Since the heat source provided by the compressor is much smaller than that of the conventional evaporator, the temperature difference can be realized, the product can be greatly improved, and the scaling can be reduced.

3) No condenser or only a small area condenser, the structure and process are very simple, fully automatic operation, continuous operation, safe and reliable.

4) The equipment is equipped with CIP cleaning pipeline, which can realize local cleaning. The whole set of equipment is easy to operate, has no dead angle, high degree of automation and stable operation.

5) The evaporator is evaporated by the material at low temperature (evaporation temperature 50℃-95℃), and it is not easy to generate foam. The liquid is uniform and does not run out of material, it is not easy to coke, and the thermal denaturation of the material is extremely small.

6) Although the initial investment amount is high, the investment return period of most projects is generally 1.5 to 2 years, and the longest is not more than 3 years.

7) The power consumption for evaporating one ton of water is 23-70kw·h.

|

scope |

type |

reactor |

single effect evaporator |

Multi-effect evaporator |

jet pump |

MVR evaporator |

|

Energy consumption |

High energy consumption, it takes about 1.5 tons of steam to evaporate one ton of water |

Energy consumption is high. A ton of steam is theoretically needed to save a ton of steam. |

Compared with the increase in efficiency, the energy consumption is correspondingly reduced. |

Traditional multi-effect evaporators are based on multiple effects, but require high pressure steam to drive |

The most energy-efficient evaporator technology; 20kw/h-70kw/h power consumption |

|

|

construction area |

small |

small |

big |

big |

small |

|

|

Impact on product quality |

Evaporated product stays for a long time, which seriously affects product quality and color. |

Short residence time but large temperature difference; easy to expand; less impact on product quality. |

Longer residence time and greater temperature difference; easy to expand; less impact on product quality |

Short residence time, little impact on product quality, |

Short residence time and small evaporation temperature difference; not easy to expand; minimal impact on product quality |

|

|

energy mode |

Direct heating with coal or diesel; or steam heating. |

Requires steam heating. Requires steam network, boiler heating requires steam |

Requires steam heating. Requires steam network, boiler heating requires steam |

Requires steam heating. Requires steam network, boiler heating requires steam |

Using power, no steam pipe network, fully self-closed circulation system

|

|

|

self-control |

Manual operation |

semi-automatic control |

Fully automatic control operation, continuous evaporation |

Fully automatic control, continuous evaporation |

Fully automatic control, continuous evaporation |

|

A. Environmental protection industry

1. High-salt industrial wastewater

2. Environmentally friendly saline wastewater

3. Landfill leachate chemical industry

4. Pharmaceutical wastewater

5. Production of saline wastewater

6. Chemical product concentration or crystallization

7. Mine wastewater treatment

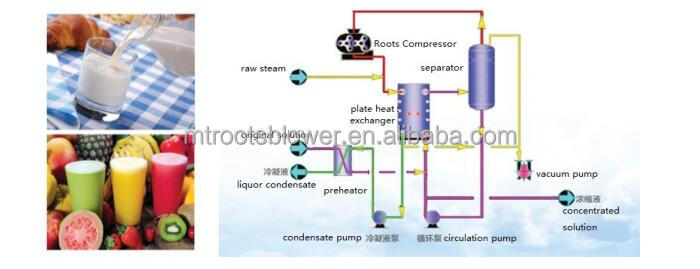

B. Food Industry

Concentration and extraction of sugar, milk, fructose, soft drinks, beverages, amino acid concentration, etc.

-

Collagen making machine

-

Lab1st Rotovap 5l Rotary Vacuum Evaporator Price

-

Best Selling Smart Watch D20 y68 Big Screen Smart Watch I7pro Max Smart Watch Iwo Series 7 Smart Watch I7 Pro Max

-

Laboratory essential oil extraction water distiller purifier distillation device

-

Fully automatic essential oil distiller distillation equipment machine water pure dew perfume aroma DIY tea tree stainless steel

-

Automatic Essential Oil Vacuum Steam Distillation Extraction Machine Equipment Tank Instrument Kit Plant Herb 50L 100 5000 Liters

-

Small pure steam generators for the pharmaceutical and healthcare industries

-

ZZKD glass laboratory equipment vacuum distillation system kit 2l 5l 10l 20l short path distillation

-

Small Essential Oil Extractor Extraction Distiller Distillation Distillation Equipment Machine Instrument Kit Kit Unit Set Equipment

-

China Famous Brand Low Price MVR Evaporator