14mm diameter alumina ignition electrode for gas burner

-

Supplier: Yangzhou Burning Ignition Equipment Co., Ltd. -

Region: Jiangsu, China -

Price: $1.00 / >=100 pieces -

Min. Order: 100 pieces

Product details

| Advantage: | Hot and cold manufacturing process quality | Key words: | 14mm diameter alumina ignition electrode for gas burner |

| Supply capacity: | 1,000,000 pieces/month | Packaging Details: | Carton (350*190*230cm) or as your request diameter 14mm alumina ignition electrode for gas burner |

| model: | BNDH | Certificate: | International Organization for Standardization |

| payment terms: | Letter of Credit, T/T, Western Union, MoneyGram | feature: | environmentally friendly |

| Free samples: | usable | place of origin; place of origin: | Jiangsu, China |

| ID: | Laser Marking | color: | customer request |

| application: | Gas stoves/burners/boilers/industrial equipment | port: | Shanghai/Ningbo |

| brand: | Burn/OEM | Material: | Alumina - Zirconia, 95% Alumina, Kanthal-A1 |

| Pay: | wire transfer, letter of credit | type: | Electrothermal ceramics |

Product Description

14mm diameter alumina ignition electrode for gas burner

| Alumina (Al2O3) Ceramic Parameters List | ||||||||

| Alumina (Al2O3) | ||||||||

| Main technical characteristics of iron-chromium-aluminum electric heating alloy (GB/T1234-95) | ||||||||

| 1Cr13A14 | 1Cr21A14 | |||||||

Related Products

Click here to customize exclusive products!

customized product

our company

our exhibition

Hot Show

Packaging and Delivery

FAQ

VIEW MORE

You may like

-

High purity C799 alumina ceramic protection tube for thermocouple 99 Al2o3

-

ANSI high voltage pin type suspension porcelain insulator

-

High-purity 99.8% alumina ceramic protective tile

-

High quality and lowest price glazed porcelain bobbin insulator ansi 53-1

-

Piezoelectric ceramic ultrasonic microporous nebulizer, working time more than 5k hours

-

18mm 36KHZ piezoelectric ceramic element

-

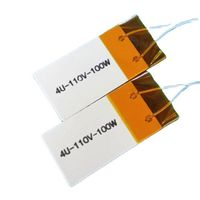

110v 220v ultrasonic cleaner heater aluminum MCH ceramic heating element OEM

-

Heater

-

Diameter 12MM 15MM Piezo Ceramic Brass Disc Alarm Sound Piezo Ceramic Plate Buzzer with 60MM Wire

-

Ceramic Manufacturer Repair Parts Piezoelectric Ignition Piezoelectric Spark Ignition Switch

Other Products

-

$1.00 / piece

$1.00 / piece