HSS Combination Center Bits Set DIN333 Type A 60 Degree HSS Metal Center Bits

-

Supplier: Shandong OLI Machinery CO.,LTD -

Region: Shandong, China -

Contact: Mr Wenguo Ocut -

Price: $0.70 / >=10 pieces -

Min. Order: 10 pieces

Product details

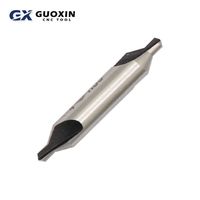

| product name: | HSS center drill | process: | fully ground, milled |

| Point angle: | 60 | flute: | Straight slot, 2 slots |

| Warranty: | a month | payment terms: | L/C,Western Union,D/P,D/A,T/T,Paypal |

| Supply capacity: | 1000 boxes per month | Packaging Details: | carton |

| Card: | Ochet | Surface treatment: | Bright, Black, Black Gold, Black Bright, Coffee, Rainbow, Tin Plated, Bright (Uncoated) |

| port: | Qingdao, Ningbo, Shanghai | size: | 0.5mm-18mm |

| Countersunk angle: | Center 60 degrees | Material: | HSS4241, 4341, 6542(M2), Carbide, M35, M42 |

| standard: | DIN333A, DIN333B, DIN333R, extra long, GOST 14952-75 | use: | Metal center drilling |

| Custom Support: | OEM, ODM |

product description

HSS Combination Center Bits Set DIN333 Type A 60 Degree HSS Metal Center Bits

Definition of center drill: prefabricated precision positioning for hole processing, guided twist drill for hole processing,

Reduce errors. The center drill is used to machine the center hole of the end face of parts such as shafts.

This product cuts quickly and removes debris well.

Reduce errors. The center drill is used to machine the center hole of the end face of parts such as shafts.

This product cuts quickly and removes debris well.

HSS Center Drill

There are two types of center drills:

Type A: Center drill without cone guard

Type B: Center drill with tapered shroud

When machining a center hole with a diameter of d=1~10mm, the center drill does not have a cone shield (type A); for longer workpieces

Process and higher precision requirements, in order to avoid damage to the 60 degree centering cone, center drill with guard

Cone (Type B) for general use

Type A: Center drill without cone guard

Type B: Center drill with tapered shroud

When machining a center hole with a diameter of d=1~10mm, the center drill does not have a cone shield (type A); for longer workpieces

Process and higher precision requirements, in order to avoid damage to the 60 degree centering cone, center drill with guard

Cone (Type B) for general use

Instructions for use of the center drill:

1. The user must reasonably select the center drill model according to the hole type and straight hole size of the machined parts.

2. The hardness of the workpiece to be processed is between 170-200HB. 3. Before using the tool, it must be coated with anti-rust grease

Clean up to prevent chips from sticking to the cutting edge and affecting cutting performance. 4. Surface

The workpiece to be processed should be straight, without air bubbles or hard spots, so as not to damage the tool.

2. The hardness of the workpiece to be processed is between 170-200HB. 3. Before using the tool, it must be coated with anti-rust grease

Clean up to prevent chips from sticking to the cutting edge and affecting cutting performance. 4. Surface

The workpiece to be processed should be straight, without air bubbles or hard spots, so as not to damage the tool.

5. The center drill before drilling should reach the required position accuracy.

6. Cutting amount (see picture)

7. Cutting fluid: Choose different cutting fluids according to the processing object, and the cooling should be sufficient.

8. Matters needing attention: If there is an abnormal situation during the processing, it should be stopped immediately, and the reason should be found out before processing;

Pay attention to the wear of the cutting edge and repair it in time; clean and oil the tool after use, and keep it properly.

6. Cutting amount (see picture)

7. Cutting fluid: Choose different cutting fluids according to the processing object, and the cooling should be sufficient.

8. Matters needing attention: If there is an abnormal situation during the processing, it should be stopped immediately, and the reason should be found out before processing;

Pay attention to the wear of the cutting edge and repair it in time; clean and oil the tool after use, and keep it properly.

Product Specifications

Protective plastic box, this is more expensive, please confirm with us

Transparent plastic box, the default packaging

Our advantage

Our advantage:

1. We are a factory.

2. 15 years experience.

3. Excellent quality and competitive price.

4. Here are mainly milling cutters: milling cutter head, milling cutter shaft, milling cutter handle.

Boring tools: boring tools, boring heads, boring bars, boring tools and combination kits

Turning Tools: Turning Tool Holders, Blades, Tool Holders, Tool Kits and Combination Kits

2. 15 years experience.

3. Excellent quality and competitive price.

4. Here are mainly milling cutters: milling cutter head, milling cutter shaft, milling cutter handle.

Boring tools: boring tools, boring heads, boring bars, boring tools and combination kits

Turning Tools: Turning Tool Holders, Blades, Tool Holders, Tool Kits and Combination Kits

VIEW MORE

You may like

-

Center drill 1# 2# 3# 4# 5# 6# 7# 8# HSS M2 6542 center drill bit DIN333 A type 60 degree HSS metal center drill bit

-

M35 HSSE double-sided type A tin plated center drill bit

-

Hardened HSS extended center drill A-type positioning drill bit containing cobalt titanium-plated drill bit 2/2.5/3/4/5/6*100/150

-

DIN333 Type A High Speed Steel Steering Center Drill Bits for Centering and Steering Drilling on Lathes

-

1.0-13mm HSS M35 Cobalt Coated Cobalt Drill Bit Set for Wood/Metal Hole Cutter Power Tools

-

Manufacturer HSSCO TIN HSS Coating Self Centering Drill

-

172*1 Center drill Compound center drill without guards Center drill with guard taper 173*6.3

-

Solid Carbide 5D Internal Coolant Drill Carbide Drill Bit Twist Cold Drill Tool Coated Internal Coolant Drill Bit

-

HSS DIN333 Double Head Double Head Centering Drill Bit Self-centering Centering Drill Bit For Hole Processing

-

South Korea YG carbide fixed-point drill DV301030 fixed-point chamfer drill 3.0*60 degrees

Other Products

-

$14.40 / set

$14.40 / set