Solid Carbide 5D Internal Coolant Drill Carbide Drill Bit Twist Cold Drill Tool Coated Internal Coolant Drill Bit

-

Supplier: Shenzhen Jialexing Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Julie Chen -

Price: $8.19 / 50 - 99 pieces

$6.99 / 100 - 999 pieces

$6.69 / 1000 - 9999 pieces

$5.58 / >=10000 pieces -

Min. Order: 50 pieces

Product details

| control method: | CNC milling machine | port: | Shenzhen/Guangdong/Beijing/Ningbo/Shanghai/Shandong/Qingdao |

| coating: | AlTiN, TiAIN, TiCN, TiSiN, tin (other coatings can be customized) | Supply capacity: | 300000 pieces per month |

| MOQ: | 50 | application: | Carbon iron alloy steel mold steel for castings |

| Surface treatment: | Bright (uncoated), ultra-long life TiAlN | Human Resources Committee: | HRC45/55/60/65 |

| point angle: | 120°,140° | Packaging Details: | Our standard packing 1. Each carbide drill bit with plastic tube, 10 pcs per set 2. Then packed in carton with bubble film Other packing is available as your request |

| usage: | normal/high speed | product name: | 140 degree 5D internal cooling drill bit |

| Product angle: | 140 degrees | payment terms: | L/C, Western Union, D/P, D/A, T/T, MoneyGram |

| Package preview: | Customization support: | OEM production | |

| Material: | Carbide, 100% new material |

Product Description

product name | 140 degree solid carbide 5D internal cooling drill bit | |

Material | Hard alloy, tungsten steel | |

Human Resources Committee | HRC45/55/60/65 | |

coating | AlTiN, TiAIN, TiCN, TiSiN, Tin (Uncoated/Other different coatings can be customized, according to the processing material selection) | |

OEM production | Support non-standard customization | |

product angle | 140 degrees | |

apply to | For casting carbon iron alloy steel mold steel stainless steel copper aluminum alloy steel wood plastic etc. | |

High-speed cutting applications with higher strength due to particulate cemented carbide material | ||

Cutting edge coating increases bit hardness for longer life, increases surface finish and saves manufacturing time | ||

Anti-seismic design, smooth chip removal, reducing burrs during product processing, and improving processing efficiency | ||

Large-capacity spiral blade design, smooth chip removal, not easy to stick to the knife, reduce heat, sharp cutting edge, durable | ||

Click here for free samples | ||

super ingredient

thing | HRC45 | HRC55 | HRC60 | HRC65 |

grade | YG10X | YL10.2 & WF25 | Germany K44&K40 | Sandvik H10F |

detail | Particle size 0.7um, Co10%, | Particle size 0.6um, | Particle size 0.5um, Co12%, | Particle size 0.5um, |

Bending strength | Co10%, curved | Bending strength | Co10%, curved | |

3320N/mm2 | Strength 4000N/mm2 | 4300N/mm² | Strength 4300N/mm2 |

A good coating can improve tool life and productivity and solve cutting problems

coating | hardness | thickness | coefficient of friction | oxidation temperature | color |

high pressure | Um | ||||

aluminum nitride | 3500 | 2.5-3 | 0.3 | 900 | Black |

Titanium nitride | 2800 | 2.5-3 | 0.3 | 900 | Purple |

Titanium nitride | 3600 | 3 | 0.45 | 1000 | copper |

AlTiSi | 400 | 3 | 0.4 | 1200 | blue |

tin | 2500 | 2-3.0 | 0.5 | 600 | the gold |

Product Description

Customized service

our service

Welcome to be our agent, or OEM customization; Different hardness is provided according to customer requirements, suitable for various steel materials, molds, alloy aluminum and cast iron processes; can be produced according to your drawings or samples; If you want to know more about our products, please Contact me anytime.

VIEW MORE

You may like

-

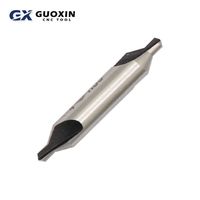

Center drill 1# 2# 3# 4# 5# 6# 7# 8# HSS M2 6542 center drill bit DIN333 A type 60 degree HSS metal center drill bit

-

M35 HSSE double-sided type A tin plated center drill bit

-

Hardened HSS extended center drill A-type positioning drill bit containing cobalt titanium-plated drill bit 2/2.5/3/4/5/6*100/150

-

DIN333 Type A High Speed Steel Steering Center Drill Bits for Centering and Steering Drilling on Lathes

-

1.0-13mm HSS M35 Cobalt Coated Cobalt Drill Bit Set for Wood/Metal Hole Cutter Power Tools

-

Manufacturer HSSCO TIN HSS Coating Self Centering Drill

-

172*1 Center drill Compound center drill without guards Center drill with guard taper 173*6.3

-

HSS DIN333 Double Head Double Head Centering Drill Bit Self-centering Centering Drill Bit For Hole Processing

-

South Korea YG carbide fixed-point drill DV301030 fixed-point chamfer drill 3.0*60 degrees

-

High Precision HRC45 Blade CNC Spot Drill NC Spot Drill

Related Search

solid carbide reamer bit

solid carbide indexable drill

solid carbide square hole drill

solid carbide inch drill

solid carbide drill reamer

cnc drill carbide center bits steel

pcd solid carbide reamers

solid carbide metal cutting tool

solid carbide round bar

solid carbide square end cutter cutting tools