Pig farm, sheep farm automatic prefabricated manure leakage board production line manufacturer price

-

Supplier: Guangxi Hongfa Heavy Machinery Co., Ltd. -

Region: Guangxi, China -

Contact: Mr David Yang -

Price: $25000.00 /set -

Min. Order: 1 set

Product details

| Warranty: | 1 year | Packaging Details: | Seaworthy packaging (with plastic film). Electrical equipment packed in wooden boxes. |

| Packaging Preview: | Health status: | new | |

| place of origin; place of origin: | Guangxi, China | payment terms: | L/C,Western Union,T/T,MoneyGram |

| Auto grade: | automatic | Function: | clean |

| color: | customer request | weight: | 10000kg |

| port: | Qingdao Port | application: | farm |

| product name: | Leaky manure plate making machine | Mechanical Capability: | depending on size |

| usage: | farm manure | brand: | Hongfa |

| Key words: | automatic | where to use: | farmland |

| Key machines: | Sheller | Raw materials: | cement sand |

| Voltage: | 220V/380V, 3-phase | Supply capacity: | 30 sets per year |

product description

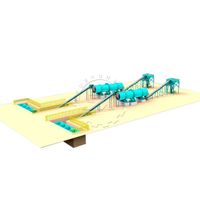

Concrete leakage board production line

Leaky manure board production line is a necessary process for building a modern pig farm. The integrated production line developed and manufactured by Guangxi Hongha Heavy Machinery Co., Ltd. has the characteristics of high degree of automation, high efficiency and energy saving, and convenient operation. Built to last. Remote control production, flexible and agile, safe and reliable.

The whole production line includes cloth system, feeding system, vibration system, automatic coating system, automatic mold turning system, motion system and hydraulic plate stacking system.

One set of mixing system can be shared by multiple molding lines, which greatly saves the cost of main equipment, labor cost, land space and auxiliary equipment investment.

Product configuration

This is a newly developed pig farm leaking manure concrete slat production line machine with the following advantages:

1. High production efficiency:

Automatic operation of the whole process: automatic concrete batching, automatic mixing, automatic feeding, forming, demoulding. A single line of 50 to 150 pieces can be produced in an 8-hour shift. The capacity depends on the size of the slatted board.

2. Flexible for different sizes of pig farm drain slats:

The slat machine can produce leaky slats of various sizes and thicknesses by changing the mold accordingly. The most commonly used lengths of concrete slats are:

Length: 1500mm to 3000mm, also can be customized length.

Width: 600mm to 1200mm, or customized.

Thickness: 100mm, 120mm, or customized

3. The finished product is widely used:

The application of this kind of manure leakage board such as pig farm floor and cattle farm floor has very positive significance

It is of great significance to environmental protection.

1. High production efficiency:

Automatic operation of the whole process: automatic concrete batching, automatic mixing, automatic feeding, forming, demoulding. A single line of 50 to 150 pieces can be produced in an 8-hour shift. The capacity depends on the size of the slatted board.

2. Flexible for different sizes of pig farm drain slats:

The slat machine can produce leaky slats of various sizes and thicknesses by changing the mold accordingly. The most commonly used lengths of concrete slats are:

Length: 1500mm to 3000mm, also can be customized length.

Width: 600mm to 1200mm, or customized.

Thickness: 100mm, 120mm, or customized

3. The finished product is widely used:

The application of this kind of manure leakage board such as pig farm floor and cattle farm floor has very positive significance

It is of great significance to environmental protection.

Introduction of green facility leaking manure board making machine and pig/sheep farm leaking manure slat production line:

---1. The raw material batching machine automatically prepares concrete.

---2. Cement, aggregate and water automatically enter the mixer.

---3. The mixed concrete is transported to the hopper of the forming machine.

---4. The molding machine feeds the material into the mold.

---5. Vibration suppression

---6, the slat surface is completed

---7. Demodulation

---1. The raw material batching machine automatically prepares concrete.

---2. Cement, aggregate and water automatically enter the mixer.

---3. The mixed concrete is transported to the hopper of the forming machine.

---4. The molding machine feeds the material into the mold.

---5. Vibration suppression

---6, the slat surface is completed

---7. Demodulation

Sales and Service Network

our service

pre-sale service

(1) Professional advice (matching raw materials, machine selection, construction conditions, feasibility analysis)

Green facility leaking manure board production line / leaking manure board machine production line)

(2) Selection of equipment model (recommended the best machine according to raw materials, capacity and brick size)

(3) 24-hour online service

(4) Welcome to visit our factory and production line anytime.

(5) Introduce company files, product categories and production processes.

(6) Raw material sample testing support.

Sales

(1) Timely update the production schedule

(2) Quality Supervision

(3) Product acceptance

(4) Ship on time

After sales

(1) Training on the installation method of the green facility leaking manure board production line/manure leaking board machine production line, and training the use of the green facility manure leaking board production line/manure leaking board machine production line.

(2) Engineers who can repair machinery overseas.

(3) Regularly visit customers, get feedback in time, and maintain good mutual communication

pre-sale service

(1) Professional advice (matching raw materials, machine selection, construction conditions, feasibility analysis)

Green facility leaking manure board production line / leaking manure board machine production line)

(2) Selection of equipment model (recommended the best machine according to raw materials, capacity and brick size)

(3) 24-hour online service

(4) Welcome to visit our factory and production line anytime.

(5) Introduce company files, product categories and production processes.

(6) Raw material sample testing support.

Sales

(1) Timely update the production schedule

(2) Quality Supervision

(3) Product acceptance

(4) Ship on time

After sales

(1) Training on the installation method of the green facility leaking manure board production line/manure leaking board machine production line, and training the use of the green facility manure leaking board production line/manure leaking board machine production line.

(2) Engineers who can repair machinery overseas.

(3) Regularly visit customers, get feedback in time, and maintain good mutual communication

Packing and shipping

VIEW MORE

You may like

-

Hot selling high quality special rubber conveyor belt for mobile bulk

-

Flour mill fully automatic 15TPH grain and wheat processing cleaning and sorting line

-

Complete set of wood bead machine wood products production line

-

1-3TPH coffee bean/seed processing line, complete set of equipment from cleaning, separation, sorting, grading, polishing to packaging

-

Small Home Asparagus Harvester High Yield Electronic Asparagus Harvester

-

Automatic Biscuit Production Line Small Biscuit Biscuit Making Machine

-

Grain Color Sorter/Rice Production Line Color Sorter/Color Sorter

-

10 tons of wheat flour machine/wheat flour machine/wheat processing line

-

20 tons per hour BB fertilizer mixer works continuously

-

Cheap oyster mushroom planting production line

Other Products

-

$15000.00 / piece

$15000.00 / piece -

$10000.00 / set

$10000.00 / set

Related Search

automat wet wipe make machin product line suppliers

full-automatic production line for lithium battery

automatic crumb powder production line suppliers

orange automatic production line orange

pu sandwich panel production line automatic

automatic candle production line suppliers

layer poultry farming cages automatic

organic farming manure suppliers

indoor fish farming equipment

fish farming equipment