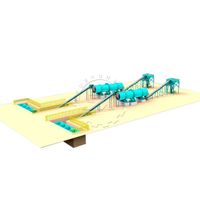

10 tons of wheat flour machine/wheat flour machine/wheat processing line

-

Supplier: Shijiazhuang Huanpai Machine Co., Ltd. -

Region: Hebei, China -

Contact: Mr Hussein Ali -

Price: $17000.00 /set -

Min. Order: 1 set

Product details

| Health status: | new | product name: | Wheat Flour Mill/Wheat Processing Line |

| brand: | Change cards | Supply capacity: | 100 sets per month |

| Automatic level: | automatic | strength: | 53 kW |

| Mechanical test report: | if | Voltage: | 380V |

| weight: | 880 kg | Packaging Details: | Standard export packaging |

| Mechanical Capabilities: | 10 tons/day | model: | 6FTP-10T |

| port: | Newport | Key machines: | sheller |

| Showroom location: | Egypt | Origin: | Hebei china |

| payment terms: | L/C, Western Union, D/P, D/A, T/T, Money Gram, Cash | Applicable industries: | manufacturing plant |

| Warranty: | 2 years | Core component warranty: | 2 years |

| Core components: | PLC | Local service locations: | Egypt |

| After Warranty Service: | Video Technical Support | Video outbound inspection: | if |

Company Profile

card returning machine

Shijiazhuang Huanpai Machinery Co., Ltd. is a professional manufacturer of various wheat/corn/corn flour machines,

Our production capacity is from 10 tons to 1000 tons per day. We can provide customers with turnkey projects from factory layout, equipment manufacturing, production line setup to operator training.

Our production capacity is from 10 tons to 1000 tons per day. We can provide customers with turnkey projects from factory layout, equipment manufacturing, production line setup to operator training.

Product Description

Introduction:

1. Cleaning process: one screen, one wash, one stone removal, one wash, one baffle.

2. Milling part technology: two 6F1820 double-roller mills, milling technology consisting of four breaking machines, two reducing machines, and one bran brushing machine

3. Production capacity: 10 tons of wheat/24H.

4. Power supply: about 31kW.

5. Conditions of use: voltage: 380V, frequency: 50HZ, altitude below 1000m.

6. The form and size of the factory building: Triangular frame factory building, 2m long, 5.0m wide, and 4.0m under the beam.

2. Milling part technology: two 6F1820 double-roller mills, milling technology consisting of four breaking machines, two reducing machines, and one bran brushing machine

3. Production capacity: 10 tons of wheat/24H.

4. Power supply: about 31kW.

5. Conditions of use: voltage: 380V, frequency: 50HZ, altitude below 1000m.

6. The form and size of the factory building: Triangular frame factory building, 2m long, 5.0m wide, and 4.0m under the beam.

7. Container: 20' x 1

8. FOB Xingang price is 17'000$

8. FOB Xingang price is 17'000$

6FTP-15T wheat flour machine

Raw materials → wheat cleaning machine → wheat moisturizing machine → roller mill → high-level sieve → high-quality flour → packaging

The wheat flour machine can be divided into three parts:

1. Clean up part of the electric wheat flour machine

Removes small and medium impurities from wheat. Such as dust, stones, magnetic substances, wheat bitten by insects, etc.

Includes beating, screening, destoner, magnetic separator and wetting. This section prepares the part for milling and

Also protects machinery. 2. milling part

In the second step, the grain is milled and the flour, bran and other by-products are separated:

(1) Grinding machine: through the movement of the drum, the grain is ground to destroy its integrity. wheat flour machine

(2) Sieve: to separate by-products such as flour and bran, and to separate large and small grains to ensure the quality of flour

3. Packaging part

In the third step, the packaging machine can weigh the package manually or automatically.

Removes small and medium impurities from wheat. Such as dust, stones, magnetic substances, wheat bitten by insects, etc.

Includes beating, screening, destoner, magnetic separator and wetting. This section prepares the part for milling and

Also protects machinery. 2. milling part

In the second step, the grain is milled and the flour, bran and other by-products are separated:

(1) Grinding machine: through the movement of the drum, the grain is ground to destroy its integrity. wheat flour machine

(2) Sieve: to separate by-products such as flour and bran, and to separate large and small grains to ensure the quality of flour

3. Packaging part

In the third step, the packaging machine can weigh the package manually or automatically.

Packaging system

The functions of the packaging system are weighing and sewing.

Packing system: The wheat flour packing machine can pack in different kinds of bags, such as 1kg/2kg/5kg/10kg/25kg/50kg.

Packing system: The wheat flour packing machine can pack in different kinds of bags, such as 1kg/2kg/5kg/10kg/25kg/50kg.

Final product

Our machines can adjust the final product according to customer's requirements

Customer visit

Our markets:

Our products are exported to Australia, USA, Algeria, Angola, Burkina Faso, Belgium, Canada, Congo, Cameroon, Ghana, Egypt, Philippines, Libya, Zambia, Kenya, Ethiopia, Yemen, Malawi, Tanzania, Tajikistan, Afghanistan, Vietnam, Israel, Mozambique, South Africa, Sudan, Somalia, Togo, Uganda, Uzbekistan, Tajikistan, Rwanda, Kazajastan and other countries.

Installation Notes

machine installation

Have never been engaged in the flour industry, do not know how to operate the flour machine?

You don't need to worry about anything, our professional Chinese engineers will go to your country to help you install machinery and train workers.

You don't need to worry about anything, our professional Chinese engineers will go to your country to help you install machinery and train workers.

After promotion:

1. Conduct technical training according to customer requirements;

2. We promise replacement within the warranty period;

3. We promise to provide maintenance spare parts;

4. Regular return visits or visits to customers;

5. Respond to emails and phone calls in a timely manner

Your complaint or inquiry..

2. We promise replacement within the warranty period;

3. We promise to provide maintenance spare parts;

4. Regular return visits or visits to customers;

5. Respond to emails and phone calls in a timely manner

Your complaint or inquiry..

VIEW MORE

You may like

-

Hot selling high quality special rubber conveyor belt for mobile bulk

-

Flour mill fully automatic 15TPH grain and wheat processing cleaning and sorting line

-

Complete set of wood bead machine wood products production line

-

1-3TPH coffee bean/seed processing line, complete set of equipment from cleaning, separation, sorting, grading, polishing to packaging

-

Small Home Asparagus Harvester High Yield Electronic Asparagus Harvester

-

Automatic Biscuit Production Line Small Biscuit Biscuit Making Machine

-

Grain Color Sorter/Rice Production Line Color Sorter/Color Sorter

-

20 tons per hour BB fertilizer mixer works continuously

-

Cheap oyster mushroom planting production line

-

70 tons per day Wheat Grinding Machinery Production Line in Wheat Flour Mill Flour Milling Plant

Other Products

-

$7000.00 / set

$7000.00 / set -

$128000.00 / set

$128000.00 / set

Related Search

10 tons tyre to oil machine

export of wheat flour suppliers

design of wheat flour mill suppliers

exporter of wheat straw

used dynapac ca25d road roller of drum road roller 10 ton

10 ton bridge crane

10 ton electric forklift price

garbage truck 10 tons

10 ton professional support jack suppliers

10 ton electric induction furnace