Batch system 10-40kg mini pyrolysis equipment with good quality and good price

-

Supplier: Shangqiu Hengchuang Environmental Technology Co., Ltd. -

Region: Henan, China -

Contact: Ms HC Wang -

Price: $8500.00 /set -

Min. Order: 1 set

Product details

| port: | Lianyungang/Qingdao/Shanghai | Marketing Type: | New Products 2020 |

| Heating fuel: | fuel and exhaust | Reactor Thickness: | 16&18mm |

| Applicable industries: | manufacturing plant, cracking plant | Packaging Preview: | |

| cooling system: | water cooling | energy consumption: | 15KW-35.5KW |

| Video external inspection: | if | Weight (kg): | 35000 kg |

| Mechanical test report: | if | Machine name: | Mini Pyrolysis Plant |

| Reactor Life: | 5-8 years | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Raw materials: | Waste tires & waste plastics & sludge & heavy oil | Steel: | Q345R&SS316L |

| Packaging Details: | 40FR(Flat rack) 40HQ(Container) 20GP Small accessories in wooden case | place of origin; place of origin: | Henan, China |

| Health status: | new | Showroom location: | not any |

| Main selling point: | multifunctional | Finished goods: | Fuel Oil & Carbon Black & Wire & Exhaust Gas |

| Core Components Warranty: | 1 year | Core components: | Engines, Bearings, Pressure Vessels, Gears |

| Warranty: | 1 year | Equipment capacity: | 5Tons-15Tons per batch |

| Supply capacity: | 15 sets per month | brand: | HC |

| capacity: | 5kg- 15 tons/batch |

video description

Product Description

Product advantages:

1. As a professional manufacturing factory, we have more than 10 manufacturing chief engineers with rich experience in manufacturing quality control.

2. Self-designed smoke purification system, waste gas combustion system, specially designed reactor internal structure to recycle waste plastics and sludge, and vacuum device of carbon emission system to help easier operation and save labor

3. ISO9001, ISO14001, CE manufacturing certificate

4. High-quality suppliers to ensure the good performance of motors, fans, high temperature resistant rollers, explosion-proof pumps, valves, etc.

5. Competitive price, flexible modular design, experience in installing and running projects, 24-hour after-sales service.

Pyrolysis Plant Model | ||||||||

Model | Reactor size | capacity | strength | Covered area (length * width) | ||||

HC-5PP | 2200*6000*16mm | 5 tons/batch | 18.5KW/H max | 15*10m | ||||

HC-10PP | 2600*6600*16mm | 10 tons/batch | 25.5KW/H max | 20*10m | ||||

HC-12PP | 2600*7500*18mm | 12 tons/batch | 30KW/H max | 20*10m | ||||

HC-15PP | 2800*8000*18mm | 15 tons/batch | 35.5KW/H max | 25*15m | ||||

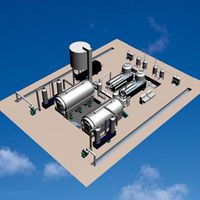

Flowchart: Pyrolysis Equipment

capacity:5Tons -15Tons/batch system

Main processing raw materials:

Used tires, used plastics (PE, HDPE, LDPE, PP, PS)

Sludge, sludge, HFO (heavy oil)

Main processing:Feeding--pyrolysis--cooling--oil collection--smoke removal--carbon discharge line

Pyrolysis plant processing time(Take 15 tons capacity as an example) | ||

feeding time | 40Mins-1Hour (via hydraulic feeder or high temperature feeder) | |

Pyrolysis time | 11-13 hours for 15-ton capacity, 9-11 hours for 10-ton and 12-ton capacity | |

cooldown | 4-5 hours | |

carbon emission time | Carbon Ejector 1 hour | |

Machine build time | 20-35 days | |

installation time | 7-15 days (reactor and cooling system are modular design, fully completed before shipment) | |

Warranty time | 12 months for the whole plant, 24 hours service for the whole life of the machine | |

Raw materials can be processed.

Waste tires, waste rubber, waste plastics (MSW, municipal waste, straw). Sludge, sludge, HFO (heavy oil)

Yield of different raw materials:

Scrap tires typically yield 40%-45% fuel yield, and truck tires or industrial tires yield about 50% fuel yield

Waste plastics have different tire oil yields according to different plastics

Heavy fuel oil provides about 65-70% fuel oil yield

Sludge yields approximately 20%-30% fuel oil yield. Due to the high water content of the sludge, the sludge is dehydrated first and then pyrolyzed.

fetalAs raw material:

Car tires, truck tires, rubber cables

Tire oil: 40%-45%

Carbon black: 30%-35%

Wire: 10%-15%

Exhaust gas: 1%-3%

plasticAs raw material:

PVC and PET are not accepted

PE plastic oil: 80%-85%

(20%-30% for some other mixed plastics)

Carbon: 5%-10%

Exhaust gas: 3%-5%

heavy oilAs raw material:

Fuel oil: 65%-70%

Residual carbon: 20%-25%

Exhaust gas: 1%-3%

sludgeAs raw material:

Fuel oil: 20%-30%

Residue: 20%-30%

Wastewater: 20%-30%

Exhaust gas: 1%-3%

pyrolysis plant composition

feeding system.

Conveyor belt: conveying whole tires, packaging plastic (10 tons capacity in 1-2 hours)

Hydraulic Feeder: Feeding cutting tires, non-packaging plastic, shredded plastic (40 minutes to 1 hour feeding 10 tons capacity

High temperature feeder: feeds tire pellets or some other smaller size raw materials

Screw feeder: feed liquid raw materials, such as sludge, heavy oil

main part

Main process: feed---pyrolysis in the reactor---cooling pool cooling---oil collection---smoke removal---carbon emission

Carbon black discharge system.

Screw discharger: suitable for small capacity or single pyrolysis machine

Vacuum unloader: 6/8/10 pyrolysis machines running at the same time

High temperature unloader: for semi-continuous cracker

Control cabinets and accessories.

Control cabinet: 1 operation panel + 1 power cabinet + alarm system

EX type water pump + oil pump

High-quality valves, flanges, graphite seals, temperature and pressure gauges, flow meters, etc.

VIEW MORE

You may like

-

Newly designed waste oil-to-diesel refinery

-

Fully Automatic Plastic Recycling Pyrolysis Diesel Tire Fuel Plant

-

Beston Group does not need to install a small pyrolysis machine for batch pyrolysis of 1-3T/D plastic tire oil sludge

-

Waste Tire Pyrolysis Diesel Plant Machine Manufacturer 5 Ton

-

Automatic control machine for biomass waste plastic tire pyrolysis machine

-

profitable small pyrolysis machine mini pryolysis plant

-

Small batch waste tire/plastic/MSW pyrolysis plant to convert solid waste into fuel oil pyrolysis machine 1-2 tons

-

New Design to Recycle Scrap Tires into Diesel with 50ppm Sulfur

-

Small integrated scrap aluminum and plastic pyrolysis plant provides fuel for machines

-

CE certified 15-50 tons automatic plastic pyrolysis plant continuous waste tire pyrolysis system

Related Search

automatic gypsum powder equipment with high quality

pyrolysis machine with recycling water cooling system

mini bakery equipment

parking system 10 sensor

10 inch plastic tool box with handl suppliers

mini usb fan with battery

pyrolysis equipment output oil

mini pyrolysis plant

mini construction equipment

mini washing machine with suppliers