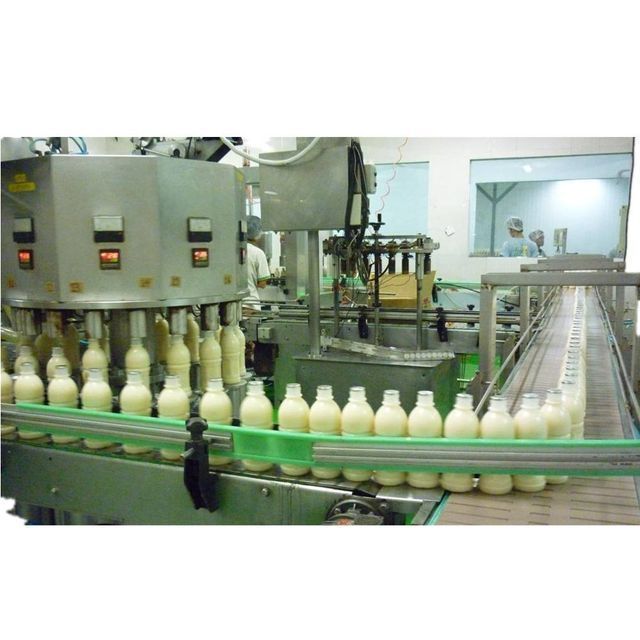

Customized Soy Milk Production Line Milk Lactic Acid Bacteria Production Line Milk Beverage Production Line

-

Supplier: Wenzhou Suote Pharmaceutical And Chemical Engineering Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms Jenny Xiang -

Price: $15000.00 / 1 - 9 sets

$10000.00 / 10 - 99 sets

$8000.00 / >=100 sets -

Min. Order: 1 set

Product details

| Video external inspection: | if | port: | Ningbo or Shanghai Port |

| Dimensions (L*W*H): | be comforted | Packaging Preview: | |

| Showroom location: | not any | Package dimensions: | 40" container |

| brand: | Salt | Mechanical test report: | if |

| Marketing Type: | normal product | Health status: | new |

| Warranty: | 2 years, 2 years | Core Components Warranty: | 1 year |

| speed: | adjustable | Features: | make them according to the properties of the plant |

| Key words: | Soy milk production line | Alcohol Injury: | 0.1(%) |

| weight: | 5000kg | Main selling point: | high productivity |

| Package: | Wooden boxes packed in containers | Packaging Details: | Export standard packing wooden box packing. |

| Supply capacity: | 100 conveyor systems per month | Material: | SUS304/SUS316/PE |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | place of origin; place of origin: | Zhejiang, China |

| payment terms: | letter of credit, wire transfer | strength: | 120KW |

| Voltage: | 380V | Applies to: | Lactic acid beverage fermentation |

| Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Mechanical Repair Stores, Manufacturing Plants, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies | Minimum order quantity: | 1 |

best seller

Product Description

1. Classification of milk production lines1. Milk production line at room temperature: using the ultra-high temperature instantaneous sterilization method, also known as UHT milk, under the ultra-high temperature of about 135 ℃, all the live bacteria and most of the spores in the milk are killed, and the retention period can reach more than 6 months . Refrigeration is not required, but nutrients are lost in significant amounts.

2. Pasteurized milk: Pasteurized milk is also called "pasteurized milk". It is pasteurized and the whole process requires 4-10 refrigerated times. It is currently more popular and largely retains the nutrients in milk. Milk with a short shelf life is mostly pasteurized "homogenized" milk. Sterilization in this way allows ideal preservation of the nutrients in the milk. It is one of the most advanced milk sterilization methods currently available. Its nutritional value is not much different from fresh milk. The loss of vitamin B is only about 10%, but some physiologically active substances may be inactivated. 3. Milk production line Fresh milk: In many developed countries, unsterilized fresh milk is more popular with consumers and is expensive. Freshly squeezed milk naturally contains antibacterial active substances such as lysozyme, and can be stored at 4°C for 24 to 36 hours. This milk does not need to be heated, and is not only rich in nutrients, but also retains some trace physiologically active components in milk, such as immunoglobulins, cytokines, growth factors, etc., which is beneficial to the growth and development of children. Moreover, the hygiene conditions of dairy farms are very high.2. Packaging materials for milk production lineMilk packaging materials: set-top box packaging, Baileys packaging, Tetra Pak packaging, Kangmei packaging and other packaging materials. Among them: Pasteurization Applicable to: glass bottles, plastic bags, set-top box packaging UHT ultra-high temperature instant sterilization Applicable to: Tetra Pak packaging, Combibloc packaging3. Process characteristics of milk production lineThe production and processing process of the whole set of equipment provided by Yingtuo Group meets the requirements of food hygiene production, and the parts in contact with the materials are made of stainless steel 304 or 316, providing customers with pre-sale (technical consultation), in-sale and after-sale ( Technical training, on-site installation) services. After the raw milk is qualified, pretreatment such as milk cleaning, cooling and storage should be carried out. The filtered and centrifuged milk should be quickly cooled to 2-3°C and stored for later use. The purpose of standardization is to make the quality of the product meet the requirements of the standard and not fluctuate with the source of raw materials. The purpose of pasteurized milk homogenization is mainly to use the powerful mechanical action of the homogenizer to break the fat globules in the milk into small particles, prevent the agglomeration and floating of the fat, and ensure the uniform, delicate and white sensory quality of the product. , to further improve the digestibility of milk quality. The purpose of pasteurization is to kill pathogenic bacteria, especially Mycobacterium tuberculosis, while minimizing the number of spoilage bacteria. Low temperature long time pasteurized milk (LTLT): 60℃~65℃, about 30min High temperature short time pasteurized milk (HTST): 80℃~85℃, 10-15s Ultra high temperature instant sterilized milk (UHT): 115℃~135 ℃, 3~5s

Introduction of equipment technology and equipment characteristics of lactic acid bacteria fermented fruit juice beverage processing production line

Process flow of fermented fruit juice beverage production line | ||

Raw material selection - + washing - + pulping - + juicing - + coarse filtration - + mixing - + homogenization - + heating - + canning + sealing - sterilization - + cooling | ||

1. Authentic fruit selection | The reason for the juice should be fresh, plump, high-quality fruit, rotten and contaminated fruit should be excluded. | |

2. Washing | Thorough cleaning of the fruit is to reduce the pollution caused by the production process, but also pay attention not to peel and squeeze the juice. Therefore, the silt and impurities on the peel must be washed with running water. If necessary, rinse with potassium permanganate solution and rinse with water. | |

3. Beaten | The pulp is beaten and peeled with a beater, and the pulp is wrapped in a special fruit cloth to squeeze out the juice, and the juice yield can reach more than 70%. Or pour the washed fruit into a press for juice, then use a spatula filter to filter the peel, seeds, and some coarse fiber. | |

4. Mix | The filtered juice was first diluted with water to a refractive index of 4%. Then according to the ratio of 90 kg of fruit juice and 10 kg of white sugar, stirring constantly, the sugar is completely melted. | |

5. Filter | The prepared juice is filtered and separated through a centrifugal filter to remove the remaining peel, fruit seeds, part of the fiber, Pulp debris and impurities. | |

6.Homogenize | The filtered juice is homogenized by a homogenizer, which can further break the fine pulp and keep the juice turbidity uniform. The pressure of the homogenizer is 10-12 MPa. | |

7. Filling | Heat the juice to 85°C~95*C, and quickly flow into the filling machine for filling and capping. 8 Sterilization and cooling: Rapid sterilization after sealing, the sterilization method is 5'--10'/100℃, and then rapidly cooled to below 40℃. | |

Over 20 years of technical experience in the field. Sot Pharmaceuticals is your trusted partner!

Effect

【Process characteristics of lactic acid beverage production line】

1. After the raw milk is qualified, milk cleaning, cooling, storage and other pretreatment should be carried out. The filtered and centrifuged milk should be rapidly cooled to 2-3°C and stored for later use. 2. The purpose of standardization is to make the quality of products meet the requirements of the standard and not fluctuate with the source of raw materials. 3. The purpose of homogenization is to use the powerful mechanical action of the homogenizer to break the fat globules in the milk into fine particles. Prevent fat agglomeration from floating, ensure the product's uniform, delicate and white sensory quality, and further improve the digestibility and absorption rate of milk. 4. The raw milk is sterilized, inoculated and then filled with solidified yogurt. The filling temperature can be slightly higher than the fermentation temperature to compensate for the temperature difference in the pipeline; while the stirred yogurt is filled after fermentation and cooling.

VIEW MORE

You may like

-

500L 1000L 2000L cheese production line mozzarella cheese making machine cheese barrel

-

Stainless Steel Cheese Making Cooking Bucket with Double Whisk

-

Ice cream production line/ice cream machinery

-

Fully automatic electric 50/L stainless steel 304 centrifugal milk cream separator

-

Stainless steel 25L new milk mixer

-

Fully automatic continuous UHT milk production line, UHT milk processing plant

-

Fully automatic ice cream factory production line equipment rod extrusion sandwich bon bon ball cone extruder

-

Small mozzarella cheese production line mozzarella cheese making machine watt

-

Hot sale cheap 200 liters vertical 100 500 liters milk cooling tank price

-

milk jug, milk bucket, stainless steel jug

Other Products

-

$2800.00 - $3250.00 / set

$2800.00 - $3250.00 / set