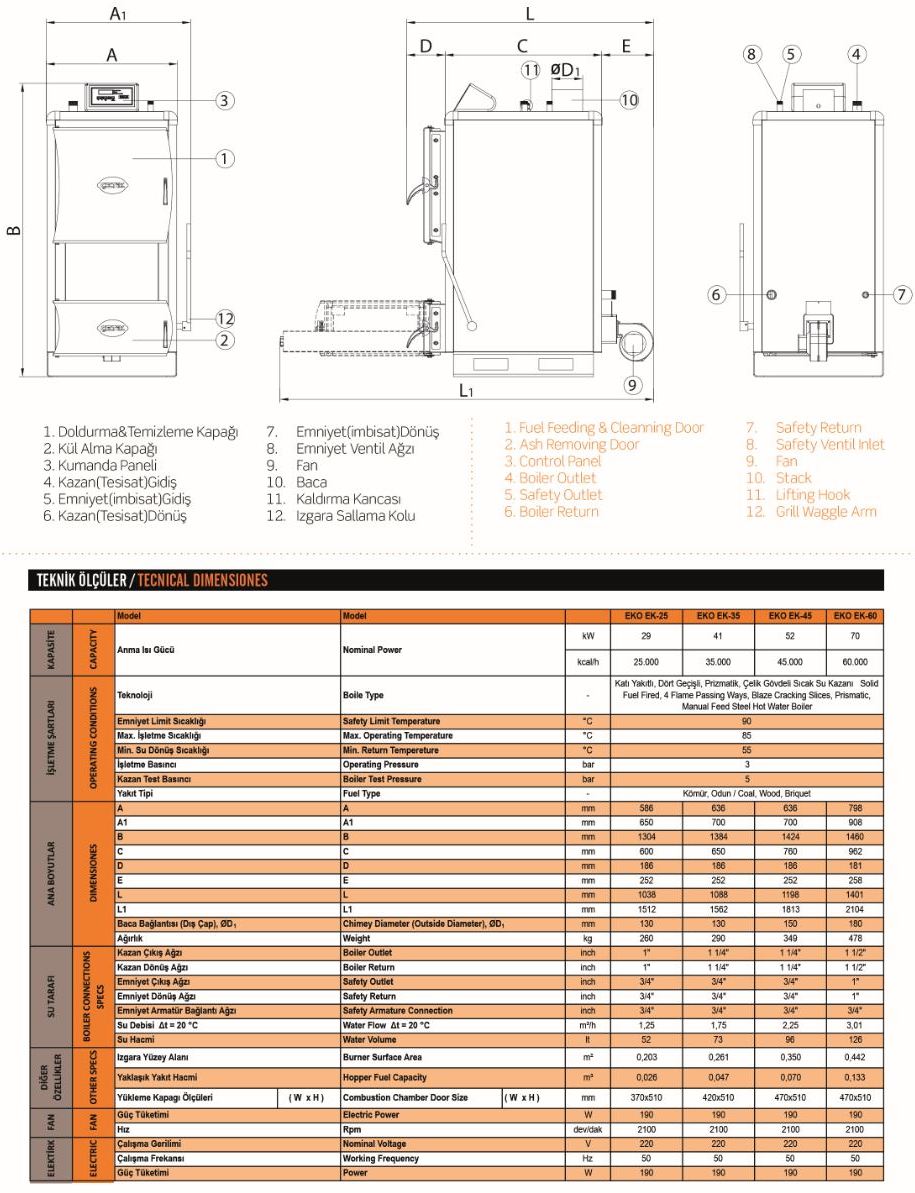

Solid fuel central heating boiler Eko EK Series

-

Supplier: CETIK ISITMA SOGUTMA SISTEMLERI INSAAT GIDA VE OTOMOTIV PLASTIK SANAYI TICARET LIMITED SIRKETI -

Region: KONYA, Turkey -

Contact: Mr KAMIL ISIN -

Price: $1150.00 / 1 - 14 pieces

$1000.00 / >=15 pieces -

Min. Order: 1 piece

| Health status: | new | product name: | Aike Aike |

| Warranty: | 2 years | payment terms: | wire transfer |

| Key words: | Manual feed boiler | place of origin; place of origin: | Konya, Turkey |

| brand: | CETIK | Delivery Details: | Ships within 0 days after payment |

| boiler: | Firewood hot water boiler | structure: | water pipe |

| Design Fuel: | firewood | Material: | Metal |

| Supply capacity: | 5000 pieces/year | type: | ventilation |

| port: | Istanbul, Mersin | pressure: | low pressure |

| After-sales service provided: | Engineers can repair machinery overseas | style: | vertical |

| Operation: | manual shooting | Certification: | ISO, CE, UKR, EAC |

| output: | hot water | color: | orange and black |

| gasoline: | burning coal | Packaging Details: | IPPC 15 Wooden Pallet |

| Thermal efficiency: | 86% | Application areas: | Residential |

| usage: | villa, residence | Function: | central heating of the house |

Specification

EKO EK wood coal boilers between 20.000-60.000 kcal/h

It is suitable for all types of wood and coal, with a large feed gate.

Our boilers are sold to: 60 countries; Macedonia, Bulgaria, Estonia, Lithuania, Latvia, USA, Italy, Georgia, Peru, Ukraine, Russian Federation, Korea, Spain, India, Austria, United Kingdom, Bosnia Herzegovina, Ireland, Hungary, Brazil, Chile, Romania. All our references are very strong.

We use top quality materials and employ qualified workers.

* Cetik Isi Sanayi boilers are designed for optimum efficiency, economical use of your fuel due to the internal structure and servo motor system. All our boilers are designed according to 4 pass methods. Thanks to BAFIL, (4 passes) system; efficient use of thermal energy from fuel. It's more economical than other boiler brands that use plumbing. In tests carried out at the Laboratory of Mechanical Engineering and Environmental Engineering of the University of Selcuk, it was proved that the coal you burn returns heat again at 88%.

*We use a water roasting system in the design of the fully automatic boiler. Because of the high temperatures in the hell (combustion chamber), steel doesn't last that long and generally goes bad. But with a water roasting system, this temperature is not so high. Cold water goes through this water grill to where the hell is (the combustion chamber), so it's possible to keep the temperature at a standard rate.

You buy 1 trial version and try it, then you decide. We are very pretentious..

high efficiency

The ergonomic control panel, boiler tubes and fire attack area, which are highly efficient, together result in a special interior design and water roasting system.

Use the facility

With the large filler cap, fueling and ignition operations are made easy. Easy-to-use control panel, by adjusting the fan speed and boiler temperature regulation, the boiler automatically runs for maximum efficiency and economy. Due to the movable and rotating water grill, only move the ash arm to pour ash into the ashtray.

Combustion Control System

The combustion chamber has daily processing capacity. After the fan and boiler thermostat are adjusted, the air is evenly dispersed into the boiler by adjusting the speed of the fan. The boiler is brought to the state in a short time through a special interior design. After entering the system, the fan stops and the boiler burns with natural ventilation. When the boiler reaches the desired temperature, the servo motor closes the fan valve %100 and the chimney valve %80, putting the boiler into sleep mode. Thanks to this system, combustion is completely controlled, saving fuel and electricity consumption.

special fuel

Our solid fuel boilers offer designs when burning coal, lignite, wood and wood-derived fuels with high combustion efficiency and low flue gas emission values.

aesthetic design

The boiler body is completely isolated, dissipating heat, and the water grill absorbs the heat. The exterior view of the boiler is painted with electrostatic paint, which gives the boiler an aesthetically pleasing appearance.

Friends of the Environment

Benefit the most from the combustion and post-combustion gases thanks to the special interior design. Harmful exhaust and stack temperatures also increase the minimum.

-

15KW-50KW high power floor-standing mobile single heating electric boiler for heating and hot water

-

Combination boiler Electric wall-mounted heating boiler is used for central heating and hot water electric combination boiler

-

304 stainless steel electric steam boiler JDR36D

-

Industrial steam boiler with coal. Wood. High quality biomass

-

DS-ST-01A Smart Steam Generator Boiler Price Per Iron

-

wood boiler 23- 104 KW

-

Electric Steam Iron with Steam Generator DS-21A Mini Steam Generator Price

-

Dual circuit Vaillant wall-hung boilers with two heat exchangers for central heating and hot water are now available

-

Bosch gas wall-hung boiler stock spot German high-quality gas boiler central heating hot water

-

High Efficiency Instant Gas Boiler for Wall Mounted Gas Heating and Water Heater vs China Wall Mounted Gas Water Heater