Industrial steam boiler with coal. Wood. High quality biomass

-

Supplier: Xuzhou Double Rings Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Kun Xu -

Price: $5000.00 /set -

Min. Order: 1 set

| Core component warranty: | over 5 years | Video shipment inspection: | if |

| usage: | industrial | Packaging Details: | Airworthy export standard packaging |

| output: | steam | General picture: | supply |

| Origin: | Jiangsu, China | Basic drawings: | supply |

| Steam production: | maximum. 30 tons/hour | Main selling points: | easy to operate |

| port: | Lianyungang | structure: | fire pipe |

| fuel: | Coal or wood chips or rice, wood rice husk biomass | Installation guide: | free |

| After-sales service: | lifelong | pressure: | high pressure |

| After-sales service provided: | Engineers available to service machinery overseas | brand: | Shuanghuan |

| payment terms: | L/C, Western Union, D/A, T/T | Policy time: | one year |

| Warranty: | 1 year | Dimensions (L*W*H): | 1000 |

| Foreign agent: | In Vietnam, Sri Lanka, Ukraine | Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Manufacturing Plants, Machinery Repair Shops, Food and Beverage Plants, Restaurants, Home Use, Printing Shops, Construction, Energy and Mining, Food and Beverage Stores |

| Package preview: | Supply capacity: | 1700 sets per year | |

| type: | natural cycle | Core components: | Boiler |

| Showroom location: | Vietnam, Pakistan, Thailand, Sri Lanka, Kazakhstan, Malaysia | weight: | 25T |

| style: | horizontal | Health status: | new |

| train: | can be discussed | Factory history: | Since 1970 |

| Mechanical test report: | if |

Competitive price DZL automatic steam boiler

A: Our biomass boilers adopt many latest technologies, which make our boilers have the following advantages:

Advantages of our steam plant:

1. Low dust emission & SO2 emission & NOx emission, dust emission concentration <50mg/m³, SO2 & NOx emission concentration <100mg/m³

2. The boiler is equipped with a European-style burner, and the fuel combustion can be automatically adjusted.

3. We provide 2 sets of water pumps from famous water pump manufacturers (one for use and one for standby).

4. The boiler can realize automatic temperature control, pressure control, water supply control, feed fuel control, safety instructions... We also provide a set of electric controller internal parts for free.

5. The boiler adopts stainless steel casing, which is anti-corrosion and anti-rust, and has a beautiful appearance.

6. Perfect after-sales service. We can design the boiler system layout drawing according to your actual requirements, and we can also send engineers.

B: Main parameters and our steam boiler catalogue.

. Steam capacity: 0.1 tons to 100 tons

- Pressure: 0.4Mpa to 5.3Mpa or 4bar to 53bar

- Steam temperature: 151°C to 450°C

- Fuel: various biomass fuels (rice husks, peanut shells, coconut shells, sawdust, wood, corncobs) and coal

- Available pellet hopper types:

a: vertical and horizontal

b: single drum (DZL) and double drum (SZL)

c: Chain grate coal feeding boiler (DZL) and manual feeding type (DZH)

d: Circulating fluidized bed boiler (CFB boiler)

C: Fuels suitable for boilers are as follows:

D: The internal structure of the steam boiler:

E: Warranty: 1 year for the main body, 3 years for the parts.

1. Each boiler must undergo strict inspection and testing before leaving the factory, including hydrostatic testing and X-ray testing

2. Select the most suitable well-known brand automatic burner to match the boiler to ensure that the safety reaches the rated output

F: Our boilers include all the following supporting auxiliary engines, and customers do not need to purchase again.

1. All components, such as automatic water pumps, valves, electronic automatic controllers, automatic water level controllers, etc., are limited to international or domestic well-known brands

2. Manhole and hand hole: very convenient for maintenance

3. Applicable fuel: diesel, light oil, heavy oil 6. Provide steam for industrial users: textile mills, paper mills, printing factories, pharmaceutical factories, tobacco factories, etc.

Our customers are from all over the world, every customer is satisfied with the boiler and keeps friendly relationship. Southeast Asia, Nigeria, Sri Lanka, etc..

G: thumbnail of ths boiler

H: Delivery and installation:

The delivery time is 25 days, according to the model, we promise that we can deliver on time. For installation, we can send engineers overseas to help.

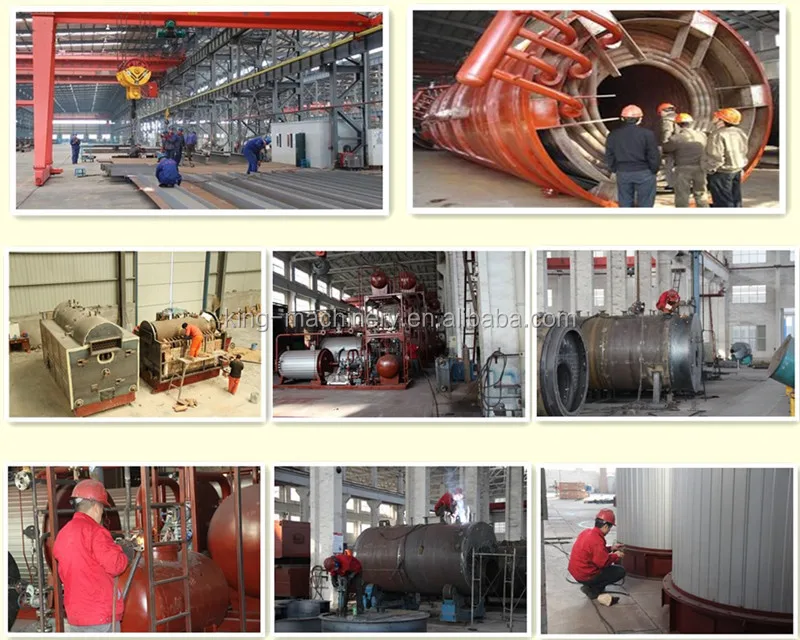

1: Our company profile

- Number of workers: about 800, senior engineers: 5, intermediate engineers: 35, junior engineers: 15, technicians: 28

- Factory area: 20,000 square meters, construction area: 80,000 square meters.

- We have a strong learning team, and the most famous learning institutions in China cooperate with us.

- Production equipment: more than 350 sets, production capacity: annual output of 6000t/h boilers, 1800 sets of pressure vessels

J: We deserve your trust:

Blow is ISO9001-2008 certificate, famous brand product certificate, environmental protection product certificate, A-level boiler manufacturing license approved by the local government.

Xuzhou Shuanghuan Machinery belongs to Golden Moon Group, specializing in the production of steam boilers, gas boilers, hot water boilers, electric boilers, shearing machines, bending machines, and CNC lathes.

Our group covers an area of 950000 square meters.The manufacturing plant covers an area of about 50,000 square meters.

It has one-stop service of scientific research, manufacturing, sales and installation.

Advanced technology and testing equipment ensure the best quality of products.

ISO9001:2000 certification.

High quality industrial coal/wood/biomass superheated steam boiler.

-

15KW-50KW high power floor-standing mobile single heating electric boiler for heating and hot water

-

Combination boiler Electric wall-mounted heating boiler is used for central heating and hot water electric combination boiler

-

304 stainless steel electric steam boiler JDR36D

-

DS-ST-01A Smart Steam Generator Boiler Price Per Iron

-

wood boiler 23- 104 KW

-

Electric Steam Iron with Steam Generator DS-21A Mini Steam Generator Price

-

Dual circuit Vaillant wall-hung boilers with two heat exchangers for central heating and hot water are now available

-

Bosch gas wall-hung boiler stock spot German high-quality gas boiler central heating hot water

-

High Efficiency Instant Gas Boiler for Wall Mounted Gas Heating and Water Heater vs China Wall Mounted Gas Water Heater

-

Pumps and in-tank solenoid coil induction heaters for house heating