Multifunctional Stainless Steel Q1 CNC Letter Bending Machine Letter Bending Machine

-

Supplier: Weifang Dayuan Machinery Co., Ltd. -

Region: Shandong, China -

Contact: Ms May zhang -

Price: $1950.00 / 1 - 4 sets

$1700.00 / >=5 sets -

Min. Order: 1 set

Product details

| Material/Metal Finishing: | aluminum alloy, aluminum | Material width: | ≤100mm |

| Main selling point: | Simple operation, dedicated to borderless letters | Video external inspection: | if |

| Warranty: | 1 year | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Core components: | PLC, motor | Packaging Preview: | |

| Mechanical test report: | if | place of origin; place of origin: | Shandong China |

| automation: | automatic | Weight (kg): | 100 |

| accurate: | 0.1mm/m | Core Components Warranty: | 1 year |

| type: | CNC automatic bending machine | Showroom location: | Russia, Malaysia |

| Supply capacity: | 500 sets per month | Minimum arc radius: | >3.5mm |

| Applicable industries: | printing shop, advertising agency | weight: | 100kg |

| port: | Qingdao, Suzhou, Guangzhou | Machine size: | 1500*500*500mm |

| Application materials: | flat aluminum | Material thickness: | 0.3-0.8mm |

| preset pressure: | 0.4-0.8Mpa | strength: | 300w |

| Health status: | new | Marketing Type: | New product |

| Packaging Details: | wooden box |

Specification

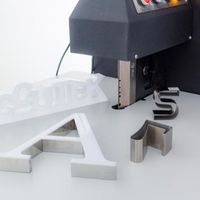

Simple to operate frameless aluminum channel letter bender for making LED 3D letter signs

Professional equipment, suitable for flat aluminum, for borderless aluminum characters, resin characters, liquid acrylic characters/super characters, side luminous characters, signs and other luminous signs. Small size, small footprint, convenient and low cost

Shipping, one-touch operation and adjustment. The best choice for your store's advertising equipment.

Shipping, one-touch operation and adjustment. The best choice for your store's advertising equipment.

Model | the first season |

working principle | Automatic feeding, slotting, bending |

Application materials | flat aluminum |

Material thickness | 0.3-0.8mm |

Minimum arc radius | >3mm |

accurate | 0.1mm/m |

Control System | Automatic bending system |

strength | 300w |

Machine size | 1500*500*500mm |

weight | 100kg |

preset pressure | 0.4-0.8Mpa |

Product display

Machine Features

●feeding system

The feeding roller is upgraded with built-in rolling bearing, which is more stable and durable, with less resistance and smoother feeding.

Closed-loop detection system ensures accurate feeding length and processing error ≤0.1mm.

●Grooving system

Closed-loop detection system ensures accurate feeding length and processing error ≤0.1mm.

●Grooving system

Planer cutting, no flying chips, clean cutting and low noise.

The planer adopts the finished carbide blade, with square rail positioning, smooth cutting, easy replacement and long service life.

The planer adopts the finished carbide blade, with square rail positioning, smooth cutting, easy replacement and long service life.

●Bending system

Intelligent compensation of springback coefficient + upgraded copper shaft pipe bender increases a larger bending arc range and can bend more complex signs with smaller arcs.

●The rear plate of the upgraded fixture is inlaid with cemented carbide, which greatly improves the service life of the rear plate.

●The material plate is easy to disassemble and assemble, and the maintenance is convenient.

●The rear plate of the upgraded fixture is inlaid with cemented carbide, which greatly improves the service life of the rear plate.

●The material plate is easy to disassemble and assemble, and the maintenance is convenient.

Product configuration

feeding system

●Closed loop detection system

Ensure accurate feed lengths and machining tolerances≤0.1 mm.

Ensure accurate feed lengths and machining tolerances≤0.1 mm.

●The built-in rolling bearing of the feed roller is upgraded,More stable and durable, less resistance and smoother feeding.

Grooving system

●Plane cutting, no flying chips, clean cutting and low noise.

●Carbide finished blade + squaree guide rail positioning, stable cutting, simple replacement, long service lifeservice life.

●Carbide finished blade + squaree guide rail positioning, stable cutting, simple replacement, long service lifeservice life.

Bending system

●Intelligent compensation of springback coefficient + upgraded copper shaft elbow.

●A wider range of arc benders has been added to bend smaller arcs for more complex signs.

●A wider range of arc benders has been added to bend smaller arcs for more complex signs.

detailed picture

Sturdy support, 20mm track, to ensure the stability and accuracy of cutting

One-button operation for start, feed, and return

Oil-water separator: keep the air pressure stable at all times

sample letter

main products

VIEW MORE

You may like

-

YIKE hot-selling LED advertising aluminum character bending machine, logo groove character making machine

-

27'' 700mm acrylic manual bending machine acrylic channel letter hot bending tool hot bending plastic hot bender heater

-

CNC automatic 3D advertising word bending machine / acrylic LED sign aluminum strip bending machine

-

220V 1000W 24" 600mm Acrylic Plastic PVC Bending Machine Heater Bending Machine

-

Automated cnc logo bending machine letter making channel letter bending machine

-

Manual Groove Bending Tool

-

Round ellipse rectangle automatic PLC control custom arc aluminum profile bending machine aluminum mirror frame bending machine

-

Metal slot word punching pliers stainless steel slot word advertising production puncher tool

-

TOP Accutek Hot Sale Automatic CNC Metal Channel Letter Bending Machine All in One Indoor and Outdoor Door Plate Bending Machine Special Sale

-

Automatic CNC Metal Channel Letter Bending Machine for 3d Aluminum Profile Paper

Other Products

-

$3118.00 - $3898.00 / set

$3118.00 - $3898.00 / set

Related Search

stainless steel china potato chips making machine

stainless steel water sink seam welding machine

stainless steel bending machine sheet metal

cnc stainless steel machining part

oem precision cnc machining stainless steel parts

cnc machining stainless steel

cnc pine bending machine

stainless steel flour dough mixer machine price

304 stainless steel csk head machine screw

stainless steel braiding machine