Automatic carton flexo printing machine price Taiwan printing slotting die cutting machine carton printer slotting machine

-

Supplier: Cangzhou Lighten Import & Export Trading Co., Ltd. -

Region: Hebei, China -

Price: $45000.00 / 1 - 1 sets

$43000.00 / >=2 sets -

Min. Order: 1 set

Product details

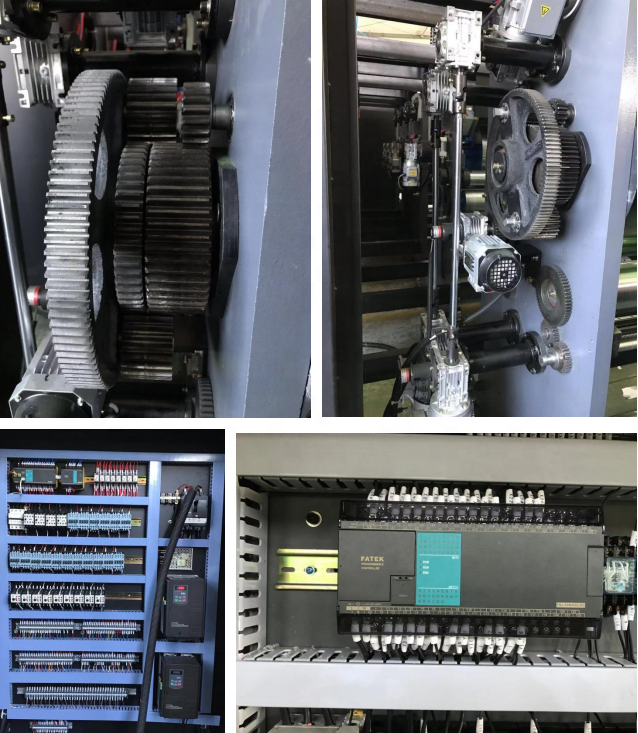

| brand: | lighten | Name: | Flexo Printing Slotting Die Cutting Machine |

| Applicable industries: | Clothing store, manufacturing factory, food and beverage factory, printing factory, construction engineering, food and beverage shop, carton industry, corrugated cardboard production industry, corrugated cardboard production factory, carton manufacturing factory, carton manufacturing industry, corrugated cardboard packaging industry, corrugated cardboard Packaging industry, corrugated box factory, corrugated box packaging industry | Weight (kg): | 25000kg |

| port: | Tianjin harbor | Health status: | new |

| application: | carton packing machine | Mechanical test report: | if |

| Showroom location: | Egypt, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, United Arab Emirates, Colombia, Algeria, Sri Lanka, Romania, Bangladesh, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan, Malaysia, Australia, none | Video external inspection: | if |

| Supply capacity: | 150 sets per quarter | Main selling point: | high productivity |

| Core components: | Gearbox, Gear, Bearing, PLC | Warranty: | 1 year |

| payment terms: | Western Union, L/C, T/T | Packaging Details: | General packaging PE film container customer demand |

| product name: | Fully automatic high-speed high-definition printing machine | Marketing Type: | Hot Products of 2020 |

| Function: | corrugated box printing slotting die cutting | Warranty: | 1 year |

| Core Components Warranty: | 1 year | Packaging Preview: |

Product Description

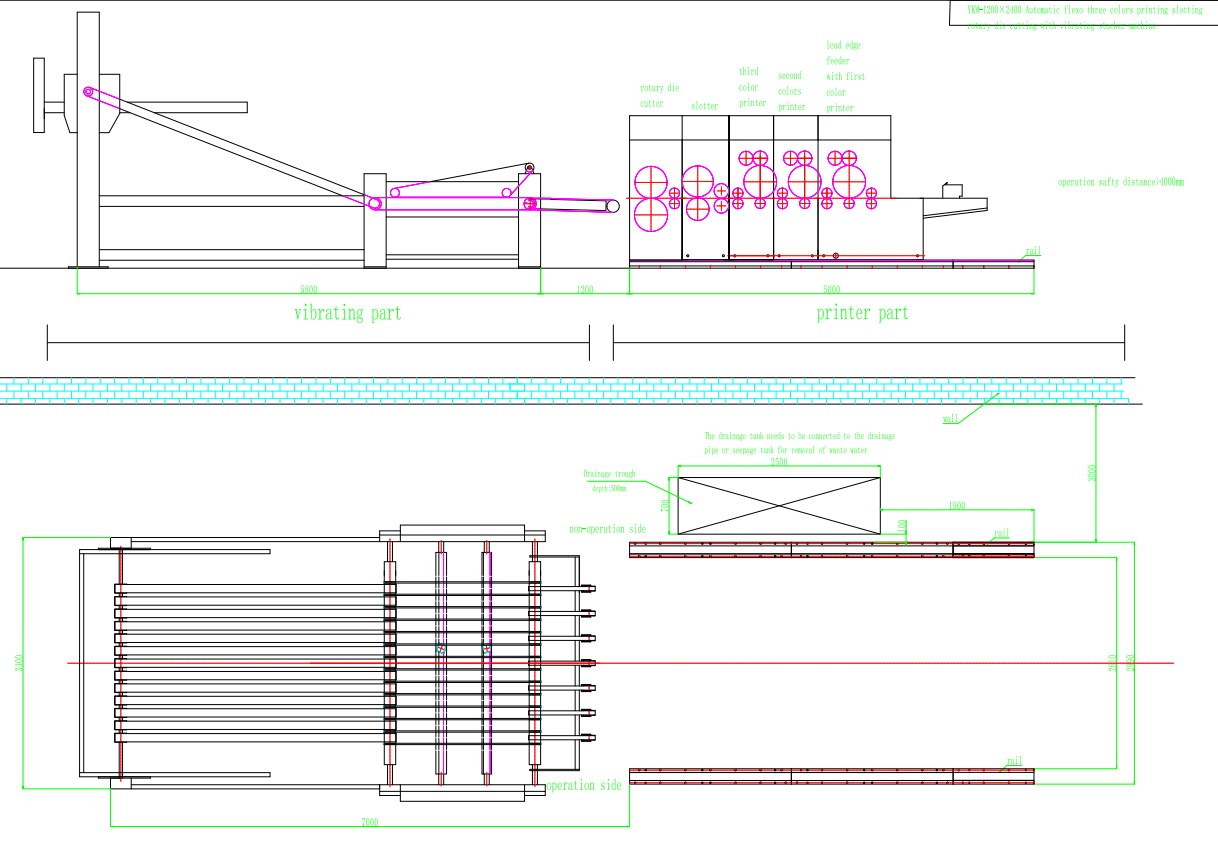

GYKM-High Speed Flexo Printing Slotting Rotary Die Cutting Belt Vibrating Stacker

Maximum paper feed size:

920×2200mm 1200×2400mm 1400×2600mm(accept customization)

Machine running speed:150~280 pieces/min(accept customization)

Machine running speed:150~280 pieces/min(accept customization)

Specification

Do not. | scope | unit | Model: GYKM-1224 | Model: GYKM-1428 | Model: GYKM-920 | |

1 | Machine size (inside) | mm | 2600 | 3000 | 3000 | |

2 | maximum. Design speed | Pieces/min | 200 | 180 | 250 | |

3 | economic speed | Pieces/min | 0-180 | 0-160 | 0-220 | |

4 | maximum. paper feed size | mm | 1200×2400 | 1400×2800 | 920×2400 | |

5 | minute. paper feed size | mm | 320×800 | 350×800 | 280×700 | |

6 | maximum. Printing size | mm | 1200×2200 | 1400×2600 | 1200×2400 | |

7 | Minimum slotting distance | mm | Negative knife: 300×100×300×100mm Positive knife: 180×180×180×180mm | Negative knife: 280×80×280×80 Positive knife: 160×160×160×160mm | ||

8 | Jump paper size | mm | 1400×2400 | 1600×2800 | 1200×2400 | |

9 | Printing accuracy | mm | ±0.5 | ±0.5 | ±0.5 | |

10 | Standard plate thickness | mm | 7.2 | 7.2 | 7.2 | |

11 | Cardboard thickness | mm | 2-10 | 2-10 | 2-10 | |

12 | maximum. Die cut size | mm | 1200×2300 | 1400×2700 | 920×2300 | |

13 | Die cutting accuracy | mm | ±1 | ±1 | ±1 | |

14 | Die-cut cardboard thickness | mm | 2-10 | 2-10 | 2-10 | |

15 | Printing Roller Axial Adjustment | mm | ±10 | ±10 | ±10 | |

leading edge feeder

Optional: 1.Zero prussure Type

2. Light pressure type

3. Ordinary style

printing unit

Optional: 1. Ceramic roller with scraper

2. Ceramic roller with rubber roller

3. Metal roller with rubber roller

2. Ceramic roller with rubber roller

3. Metal roller with rubber roller

slotted unit

Optional: 1. Computer adjustment

2. Electric adjustment

2. Electric adjustment

Die cutting unit

Optional:

1. Ordinary rotary die cutting

2. Slotting knife rotary die cutting

3. Slotting knife rotary die cutting (computer control)

1. Ordinary rotary die cutting

2. Slotting knife rotary die cutting

3. Slotting knife rotary die cutting (computer control)

Additional options:

full vacuum pipetting

The suction fan assists paper feeding. Make sure the curved cardboard feeds smoothly. Air volume can be

Adjust according to the size of the cardboard to maximize the vacuum suction of the cardboard and make the paper feeding more accurate.

Adjust according to the size of the cardboard to maximize the vacuum suction of the cardboard and make the paper feeding more accurate.

Machine Details

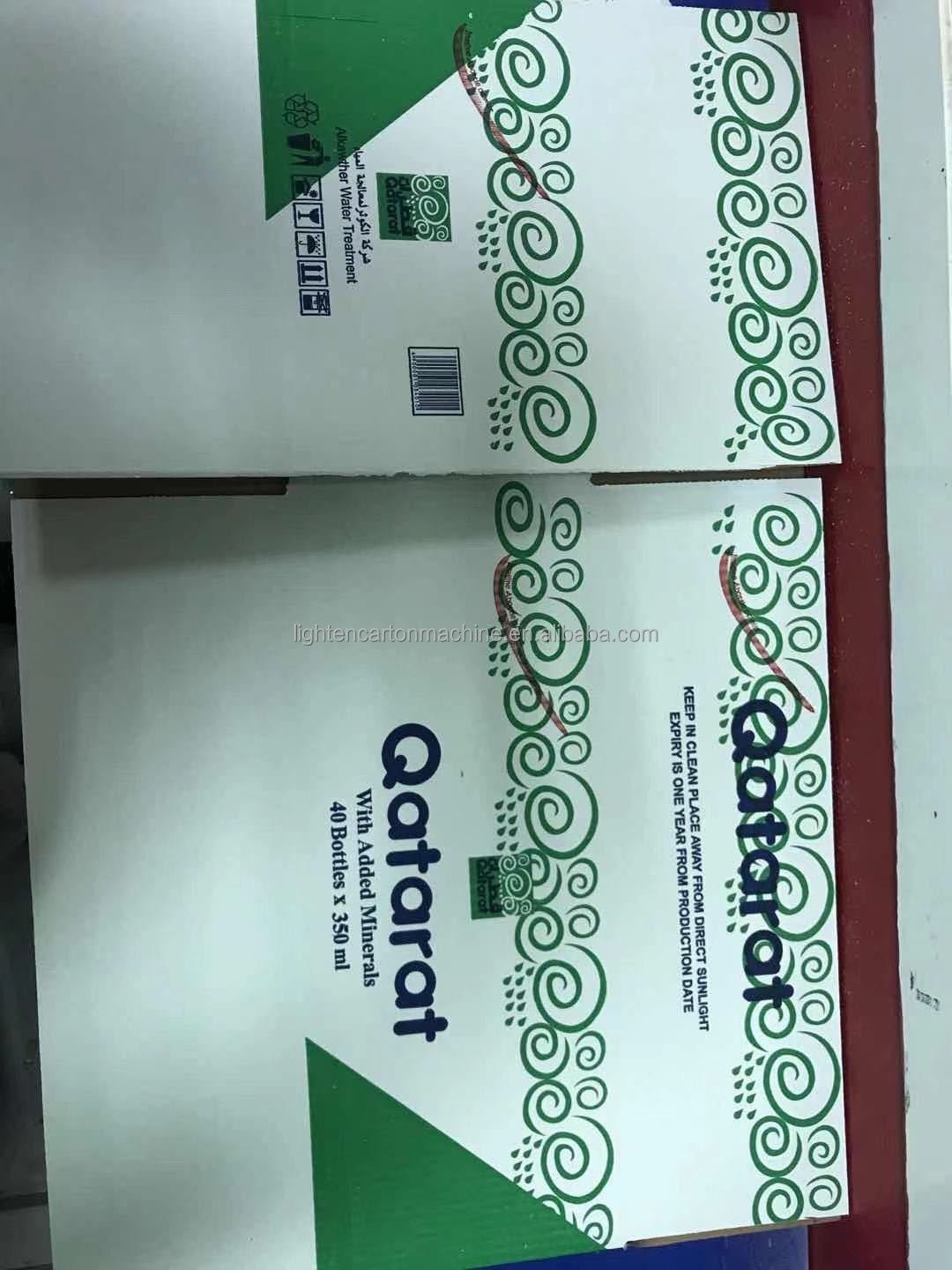

Print samples.

customer photo

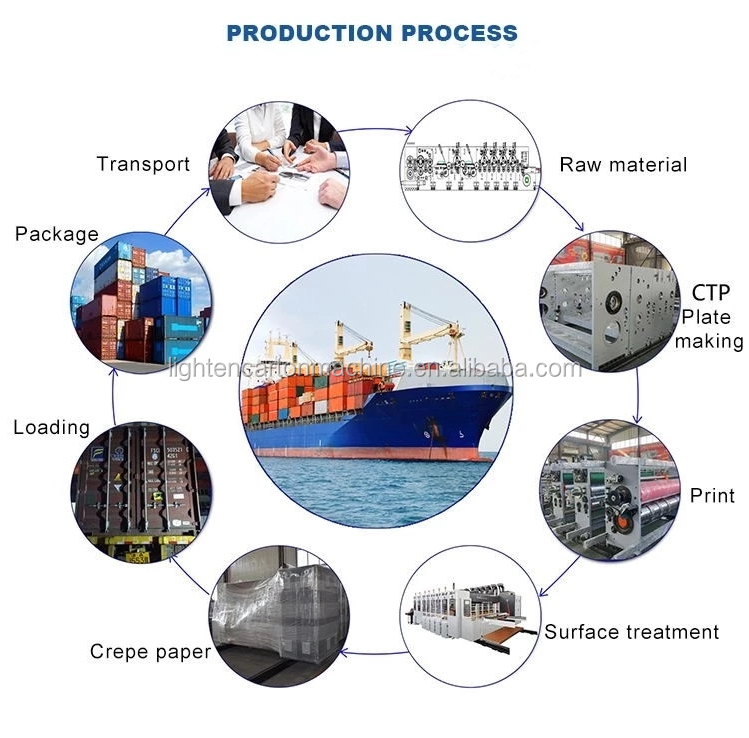

Packaging and Delivery

Company Profile

VIEW MORE

You may like

-

Chain feeder semi-automatic corrugated box 1-4 color pizza box printing machine

-

Fully automatic high-speed four-color corrugated box making machine carton printing slotting die-cutting machine

-

Tooth-shaped corrugated arc-shaped blade carton slotting machine cutting knife customization

-

Corrugated box eccentric slotting machine

-

Corrugated Cardboard Slotting Machine RS4 Corrugated Box Slotting Die Cutting Machine

-

Ocean corrugated cardboard pizza printing slotting die cutting machine

-

Corrugated box automatic flexo slotting die-cutting machine

-

HY-AA series chain feeding corrugated box printing slotting machine

-

High speed automatic carton flexo printing machine slotting machine rotary die cutting machine inline and carton folder gluer

-

Corrugated carton carton flexo paper printing machine printing box slotting die cutting machine

Related Search

automatic creasing carton flexo printing slotting

flexo printing slotting machine

flexo printing slotting die cutting machine print

auto feeding flexo printing slotting machine

flexo printing slotting die-cutting machine print

automatic wooden box printing slotting machine

automatic water ink printing slotting machine

flexo printing slotting die cutting machine

automatic paper box printing slotting machine

printing rotary die cutting machinery