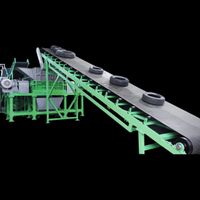

Heavy Duty Industrial Scrap Car Tire Shredder for Scrap Tire Shredder

-

Supplier: Shanghai Kraus&noble Industrial Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Linda Wu -

Price: $5000.00 /set -

Min. Order: 1 set

Product details

| Dimensions (L*W*H): | therefore | type: | Fully automatic |

| Warranty: | 12 months | payment terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram |

| Voltage: | 380V/50HZ or customized | Core Components Warranty: | 2 years |

| Supply capacity: | 150 sets per month | Key words: | high efficiency |

| Main selling point: | automatic | place of origin; place of origin: | Shanghai |

| model: | FN0001 | port: | Shanghai/Qingdao/Shenzhen/Ningbo |

| usage: | recycling waste | Raw materials: | Scrap tire tire rubber |

| color: | client needs | After-sales service provided: | Online support |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump | application: | Tire and Rubber Recycling Industry |

| Name: | tire shredder production line | Packaging Details: | export wooden box |

| brand: | OEM | Mechanical test report: | if |

| Advantage: | High capacity | Applicable industries: | manufacturing plant, other, recycling |

| Showroom location: | not any | Weight (kg): | 3000 kg |

| Video external inspection: | if | Health status: | new |

| Marketing Type: | New Products 2022 | Other names: | waste rubber tire crusher |

| Tyre machine type: | tire recycling machine |

Heavy Duty Industrial Scrap Car Tire Shredder for Scrap Tire Shredder

technical parameter

Tire pellets are mainly used to recycle waste and to make new rubber products. It can also be used to make rubber, industrial diesel, etc.

1. Tear the tire into strips less than 10 cm.

2. The tire granulator pulverizes 10cm of rubber raw materials into tire particles of about 5-8mm.

3. The crushed tire particles and the iron wire in the tire particles are preliminarily separated and magnetically separated in the crusher.

The magnetic separator is conveyed, and the qualified tire particles are conveyed to the next equipment for secondary processing.

4. The tire pulverizer grinds the tire particles into rubber particles of 1-5mm.

5. Conveying magnetic separator to cyclically screen tire particles and iron wire, qualified tires

The granules are conveyed to the vibrating screen machine.

6. The vibrating screen machine performs detailed screening according to the size of the rubber particles.

1. Tear the tire into strips less than 10 cm.

2. The tire granulator pulverizes 10cm of rubber raw materials into tire particles of about 5-8mm.

3. The crushed tire particles and the iron wire in the tire particles are preliminarily separated and magnetically separated in the crusher.

The magnetic separator is conveyed, and the qualified tire particles are conveyed to the next equipment for secondary processing.

4. The tire pulverizer grinds the tire particles into rubber particles of 1-5mm.

5. Conveying magnetic separator to cyclically screen tire particles and iron wire, qualified tires

The granules are conveyed to the vibrating screen machine.

6. The vibrating screen machine performs detailed screening according to the size of the rubber particles.

Model | input size | output size | capacity | motor | Number of blades | aspect | weight |

KN-800 | 800mm | 50*50mm | 1-2T/h | 2*22kw | 16 | 4*2.6*3.2m | 8T |

KN-1200 | 1200mm | 60*60mm | 3-5T/h | 2*37kw | 20 | 4.8*2.8*3.5m | 14T |

KN-1600 | 1600mm | 50-150mm | 6-8T/h | 2*45kw | 16-30 | 5*2*3.4m | 18T |

KN-1800 | 1800mm | 50-150mm | 7-10T/h | 2*55kw | 20-24 | 5.6*2*3.4m | 23T |

The rubber shredder adopts PLC automatic control system, which automatically reverses the control system when overloaded. The two-axle tire crusher is specially designed for low-speed high-torque used tires to minimize noise and power consumption.

The shredder blades are made of high quality steel and are Bodycote heat treated for optimum shredding performance. The shredder is easy to remove and replace the blade, suitable for shredding large, extra thick and hard materials. Crushing blades are 25mm-152mm depending on tire type, output and final product. This shredder can process OTR tires, big truck tires, car tires, etc. at a speed of 1-30 tons within 1 hour.

The shredder blades are made of high quality steel and are Bodycote heat treated for optimum shredding performance. The shredder is easy to remove and replace the blade, suitable for shredding large, extra thick and hard materials. Crushing blades are 25mm-152mm depending on tire type, output and final product. This shredder can process OTR tires, big truck tires, car tires, etc. at a speed of 1-30 tons within 1 hour.

Product Description

VIEW MORE

You may like

-

Tire Shredder Equipment Rubber Tire Shredder Recycling Machine Double Shaft Shredder

-

OEM double shaft tire shredder price shredder

-

hot sale tel shredder rubber tire twin shaft shredder

-

Industrial Recycler Plastic Wood Pallet Shredder Tire Cutter Dual Shaft Wood Shredder

-

Full automatic customizable waste tire shredding recycling machine / tyre shredder

-

waste tire recycling machine tire/tyre shredder machine price in China

-

recycling tyre machine tire cusher and tyre shredder

-

Full Automatic Whole Tire Shredder Machine Made in Qingdao Eenor Rubber Machinery Co.,Ltd

-

Used Tyre Grinding Cutting Machine Rubber Tire Crusher

-

large tyre shredding machine price waste tyre shredder for sale

Related Search

heavy duty lift car jack

heavy duty iveco truck tire

heavy duty truck tires prices

heavy duty hinges for hidden doors

heavy duty clamp for pipe

industrial machines heavy duty

heavy duty shelves for garage

heavy duty jib crane for sale

heavy duty washing machine for home

heavy duty trucks for sale in south africa suppliers