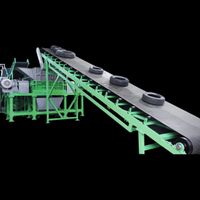

recycling tyre machine tire cusher and tyre shredder

-

Supplier: Gongyi Jinlonghengji Heavy Industry Machinery Co., Ltd. -

Region: Henan, China -

Contact: Ms sunny chen -

Price: $4500.00 / 1 - 4 sets

$4300.00 / 5 - 9 sets

$4000.00 / >=10 sets -

Min. Order: 1 set

Product details

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Marketing Type: | New Product 2020; |

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Machinery Test Report: | Provided; |

| Voltage: | 380V/460v/220V; | Single package size: | 245X365X152 cm; |

| Key word: | Tires Shredding Process Line; | Capacity: | 5t per hour; |

| Dimension(L*W*H): | it depends on the model; | Local Service Location: | Japan,Argentina,Algeria,Canada,Philippines; |

| Advantage: | higher cost performance; | Applicable Industries: | Building Material Shops,Manufacturing Plant,Food & Beverage Factory,Recycling station; |

| price: | Discount according to purchase quantity; | Packaging Detail: | Usually packed in wooden cases, which can be customized according to the needs; |

| Video outgoing-inspection: | Provided; | Warranty: | 2 years; |

| Certification: | CE ISO 9001; | Shaft Design: | Uniaxial /biaxial /quad; |

| Name: | tyre crusher tyre shredder recycling tyre machine; | Condition: | New; |

| Application: | Tyre recycling industry; | Weight: | 0.8t~31t; |

| Model Number: | SZ-600~2000; | appearance: | customization; |

| Warranty of core components: | 2 years; | After-sales Service Provided: | Field maintenance and repair service,Video technical support,Field installation, commissioning and training,Online support; |

| Key Selling Points: | Affordable price; | Showroom Location: | Morocco,UAE,Bangladesh; |

| Tire Machine Type: | Tire Recycling Machine; | Selling Units: | Single item; |

| Brand Name: | HJ; | Weight (KG): | 12000; |

| Tire recycling production line: | Shred Waste Tire; | Place of Origin: | Henan China; |

| Single gross weight: | 2000.0 KG; |

Our long-term cooperative customers

In order to expand our business scope, we are looking for high quality agents in various countries and regions. If you are

interested, please contact me:

interested, please contact me:

whatsapp :+18530909622

Email :sunnychen@hjjxc.com

Product Overview

Recycling tyre machine tire cusher and tyre shredder

Automatic control by microcomputer (PC), with functions of start, stop, reverse, overload automatic reverse, feature return and over-loading returns automatism, with characteristics of big torque in low speed, low noise. Suitable for crushing the solid material like television, washing machine, shell of refrigerator, medium size pipe, pipe fittings, forklift splint, tyres, packing barrel. Based on the original machine, closed-circuit crush until to the setting standard by rotary screen.

PRODUCT SPECIFICATIONS

No | Model | Size | feed inlet size | power | weight |

1 | SZ-500 | 2800*1300*1850 mm | 500*480 mm | 11*2 kw | 2200kg |

2 | SZ-800 | 3000*1300*1850 mm | 800*480 mm | 15*2 kw | 2500kg |

3 | SZ-1000 | 3300*1900*2200 mm | 1000*690 mm | 22*2 kw | 5200kg |

4 | SZ-1200 | 3600*2000*2200 mm | 1200*690 mm | 30*2 kw | 6400kg |

5 | SZ-1500 | 4180*2100*2400 mm | 1500*850 mm | 55*2 kw | 9000kg |

6 | SZ-1800 | 5800*2400*3300 mm | 1800*1206 mm | 75*2 kw | 13600kg |

7 | SZ-2000 | 6400*2700*3500 mm | 2000*1490 mm | 90*2 kw | 20100kg |

8 | SZ-2500 | 7500*3200*3800 mm | 2500*1800 mm | 110*2 kw | 25000kg |

9 | SZ-3000 | 8600*3500*4000 mm | 3000*1800 mm | 160*2 kw | 31000kg |

Blades

blades can be customized according to your discharging size

SALES AND SERVICE NETWORK

Successful Project

Project in Thailand

Project in Indonesia

Project in Philippines

SIMILAR PRODUCTS

Applicitations

Certificate

Company Profile

Exhibition

Our after-sales service

Pre-sale services

1 )Selecting equipment type;

2 ) Designing and fabricating the products in accordance with the special requirements of the clients;

3 )Training technical personnel for our clients;

4 ) Providing construction and technology consultations or working out proper construction schemes for those new

1 )Selecting equipment type;

2 ) Designing and fabricating the products in accordance with the special requirements of the clients;

3 )Training technical personnel for our clients;

4 ) Providing construction and technology consultations or working out proper construction schemes for those new

Services provided during the sale Respect our clients;

present the clients with ease, relaxation and a surprise; devote ourselves to improve the total value of our clients.

1)Checking products acceptance ahead of delivery;

2)Introducing the service system to our clients

After-sale services:

lmprove the added value of our products, and let the clients free from the using troubles:

1) Assisting the clients preparing for the first construction scheme;

2) Installing and testing the equipments;

3)Training the first-line operators on site;

4) Examining the equipment regularly;

5)Taking the initiatives to eliminate the failure(s) rapidly at site;

6)Distributing the guarantee fittings door-to-door;

7)Providing technical exchanging;

8)Providing maintenance for big items

1)Checking products acceptance ahead of delivery;

2)Introducing the service system to our clients

After-sale services:

lmprove the added value of our products, and let the clients free from the using troubles:

1) Assisting the clients preparing for the first construction scheme;

2) Installing and testing the equipments;

3)Training the first-line operators on site;

4) Examining the equipment regularly;

5)Taking the initiatives to eliminate the failure(s) rapidly at site;

6)Distributing the guarantee fittings door-to-door;

7)Providing technical exchanging;

8)Providing maintenance for big items

VIEW MORE

You may like

-

Tire Shredder Equipment Rubber Tire Shredder Recycling Machine Double Shaft Shredder

-

OEM double shaft tire shredder price shredder

-

hot sale tel shredder rubber tire twin shaft shredder

-

Industrial Recycler Plastic Wood Pallet Shredder Tire Cutter Dual Shaft Wood Shredder

-

Heavy Duty Industrial Scrap Car Tire Shredder for Scrap Tire Shredder

-

Full automatic customizable waste tire shredding recycling machine / tyre shredder

-

waste tire recycling machine tire/tyre shredder machine price in China

-

Full Automatic Whole Tire Shredder Machine Made in Qingdao Eenor Rubber Machinery Co.,Ltd

-

Used Tyre Grinding Cutting Machine Rubber Tire Crusher

-

large tyre shredding machine price waste tyre shredder for sale