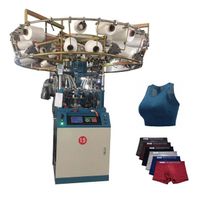

HKS3 M High Speed Warp Knitting Machine

-

Supplier: Wuhu Aris International Trade Co., Ltd. -

Region: Anhui, China -

Contact: Mr Osben Wang -

Price: $80000.00 /set -

Min. Order: 1 set

Product details

| Main selling point: | high productivity | After-sales service provided: | Video technical support, online support, free spare parts, on-site installation and commissioning training, on-site maintenance and repair services |

| Weaving method: | single | Health status: | new |

| Supply capacity: | 5 sets per month | Marketing Type: | New Products 2020 |

| Mechanical test report: | if | Local service location: | not any |

| Warranty: | 1 year | Knitting style: | through |

| payment terms: | L/C,D/P,T/T,Western Union,MoneyGram | weight: | 8000 kg |

| Measurement: | E32,18GG,16GG,28GG | Packaging Details: | vacuum packaging |

| Showroom location: | not any | Core Components Warranty: | 1 year |

| brand: | Aris | After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Product Category: | sweater, underwear | Packaging Preview: | |

| type: | Terry | port: | Shanghai |

| Applicable industries: | warp knitting | place of origin; place of origin: | Jiangsu, China |

| Weave width: | 218 inches | Dimensions (L*W*H): | 6710*1670*2322 |

| strength: | 11KW | Core components: | Motors, Bearings, Engines, Gearboxes |

| Video external inspection: | if | Production capacity: | 2200 rpm |

| Computerized: | Yes |

Product Description

Product Usage:

coating material

sportswear

Flannel for toys

decorative material

mosquito net

shoe material

curtains etc.

coating material

sportswear

Flannel for toys

decorative material

mosquito net

shoe material

curtains etc.

technical parameter | width | |

Model | HKS2/3/4 | |

working width | 186"/218"/290" | |

Measurement | E18....E28/E32 | |

bar | 2/3/4 | |

pattern drive | CD or EL | |

Let-off and take-up | EBC and electronic take-up | |

main motor power | 11kW | |

Main motor control method | Inverter control | |

Machine size | 6710x1670x2322mm | |

Speed of work | 2200 rpm | |

Main configuration | ||

main motor | Siemens, Germany | |

Inverter | mitsubishi | |

bearing | Germany SKF and INA | |

all needles on the machine | Groz-Beckert | |

Needle bar/core needle bar/needle comb bar/comb bar material | carbon fiber | |

test component | Korea AUTONICS and Japan Koyo | |

touch screen | ChinaMCGS | |

Operating components | French Schneider | |

Terminal assembly | PHOENIXCONTACT OF GERMANY | |

All machined parts | Manufactured by Tianyi Company based on karlamyer experience. | |

More information

Working widths up to 290", other machine sizes available upon request.

Wide working width, other machine gauges are available upon request.

Guide rod/stitch forming parts: needle rod, tongue rod, composite sinker, two ground wire guide rods, (one pile rod) independently inserted into the compound needle.

Beam Bracket for 2 (3) Sets of Pay-Off Systems with 30" Beam

Touch Screen/Operation Interface - Terminal

Single-speed motion control system for controlling basic functions

Optional: Yarn laser scanning automatic stop device

Let-off device:

Each let-off device is controlled by the EBA system.

Cloth collection device:

The EWA system controls the four-roller take-up, with a maximum width of 218"

Winding device:

Winding is controlled by the same motion control as the EWA.

Pattern device:

The N-type patterner consists of 2-3 pattern discs and motion changing gears.

Electronic equipment:

Speed-regulated main motor, power-off protection, low-speed transmission function, total machine capacity

Oil Supply:

Heating device, cooling through air circulation heat exchange device, pressure lubrication filling and oil injection, equipped with

With anti-dirty alarm filter.

Optional:

The water treatment heat exchange device replaces the air heat exchange device.

Wide working width, other machine gauges are available upon request.

Guide rod/stitch forming parts: needle rod, tongue rod, composite sinker, two ground wire guide rods, (one pile rod) independently inserted into the compound needle.

Beam Bracket for 2 (3) Sets of Pay-Off Systems with 30" Beam

Touch Screen/Operation Interface - Terminal

Single-speed motion control system for controlling basic functions

Optional: Yarn laser scanning automatic stop device

Let-off device:

Each let-off device is controlled by the EBA system.

Cloth collection device:

The EWA system controls the four-roller take-up, with a maximum width of 218"

Winding device:

Winding is controlled by the same motion control as the EWA.

Pattern device:

The N-type patterner consists of 2-3 pattern discs and motion changing gears.

Electronic equipment:

Speed-regulated main motor, power-off protection, low-speed transmission function, total machine capacity

Oil Supply:

Heating device, cooling through air circulation heat exchange device, pressure lubrication filling and oil injection, equipped with

With anti-dirty alarm filter.

Optional:

The water treatment heat exchange device replaces the air heat exchange device.

Size Information

Model | working width | Outline Dimensions | Measurement | Design speed |

KS2 | 186 inches | 5720*1670*2322 | E18...E28/E32 | 2200 rpm |

KS2 | 218 inches | 6710*1670*2322 | E18...E28/E32 | 2200 rpm |

KS3 | 186 inches | 5720*1670*2322 | E18...E28/E32 | 2200 rpm |

KS3 | 218 inches | 6710*1670*2322 | E18...E28/E32 | 2200 rpm |

VIEW MORE

You may like

-

Plain cord fabric two-end electric placket knitting machine

-

Semi-automatic manual flat knitting machine for home use knitting machine China

-

KH brothers semi-automatic manual manual full jacquard computer sweater leader flat knitting machine

-

KH Brother Manual semi-automatic sweater hat scarf collar flat knitting machine

-

Seamless underwear machine

-

Knitting Machine Low Price 48 Needles Circular Knitting Crochet Knitting Machine For Socks Hat Scarf Sweater Diy

-

Smart Weaver Knitting Kit Machine Oversized 48 Hand Crank DIY Wool Knitting Machine Hat Knitting Machine Toy Girl House Kids

-

48 Needles Sock Knitting Machine Small Sentro 48 Needles Circular Plastic Educational Toys Home Sweater Knitting Machine

-

Hollow round flat shoelace rope crochet machine knitting knitting machine

-

Second hand flower shima seiki new ses 122s 12g flat knitting machine

Related Search

automatic high speed blister packing machine

high speed carding textile machine

high speed cold forging machine

creel feed yarn warp knitting machine

high speed paper bowl machin suppliers

high speed medical centrifuge machine

high speed automatic cutting machine suppliers

high speed overflow dyeing machine

single needle high speed industrial sewing machine

high speed dri lamin machin suppliers