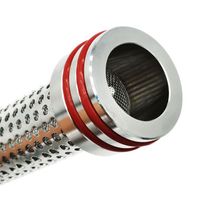

New Basket Strainer Stainless Steel Basket Strainer

-

Supplier: Shanghai Junyi Filter Equipment Co.,Ltd -

Region: Shanghai, China -

Contact: Ms Susana Wang -

Price: $520.00 / 1 - 9 pieces

$480.00 / >=10 pieces -

Min. Order: 1 piece

| Import/Export form: | Flange/inner cable/outer cable/quick installation | Shell material: | Q235B/304/304/316/316L |

| Core components: | Pressure Vessels, Pumps | Core Components Warranty: | 1 year |

| place of origin; place of origin: | China Shanghai | payment terms: | L/C,Western Union,T/T,MoneyGram |

| Video external inspection: | if | After-sales service provided: | Provide overseas third-party support |

| Marketing Type: | New Products 2020 | Packaging Preview: | |

| Applicable industries: | Hotels, Farms, Energy and Mining | brand: | Junyi |

| Health status: | new | Cover compressed form: | Bolts/Quick Bolts |

| Mechanical test report: | if | Warranty: | 1 year |

| structure: | T-type pre-filter | Weight (kg): | 50 |

| Basket form: | Perforated mesh/single-layer mesh/composite mesh | Sealing material: | teflon/rubber |

| port: | Shanghai Port | Filter form: | T Basket Strainer or Y Basket Strainer |

| Packaging Details: | Wooden crates that meet export standards. | Showroom location: | Egypt, USA, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Malaysia |

| Nominal diameter: | N15--DN600 | application: | Liquid Filtration System |

| Supply capacity: | 10 pieces per week |

Basket strainer

1. The filter is an indispensable device for conveying medium in pipeline series, and is usually installed on the side of pressure reducing valve, overflow valve, liquid level control valve or the inlet of other equipment.

2. It is used to filter out impurities in the medium to ensure the normal use of valves and equipment.

3. The filter has advanced structure, low resistance and convenient sewage discharge.

Structure and working principle of T-basket filter

Basket filters consist of connecting pipes, main pipes, filter baskets, flanges, flange covers and fasteners.

When the liquid enters the filter basket through the main pipe, particulate impurities are trapped in the filter basket. The clean liquid is discharged from the outlet through the filter basket. When cleaning is required, open the cock. Rotate the bottom of the main tube to drain the fluid. With the flange cover removed, the basket can be placed in the main tube for reuse. Therefore, it is very convenient to use and maintain.

application

1. Applicable industries: fine chemicals, water treatment systems, papermaking, automobile industry, petrochemicals, machining, coatings, etc.

2. Applicable liquid: all kinds of micro-particle liquid.

Main filtration function: remove large particles, clean fluid, protect critical equipment.

3. Filtration type: large particle filtration. Use reusable filter material. It should be cleaned manually on a regular basis.

Advantage

| 1. | Housing material: carbon steel or stainless steel 201/304/316 |

| 2. | Filter material: stainless steel |

| 3. | Sealing material: NBR, VITON |

| 4. | Diameter: 25-300mm |

| 5. | Pressure: 1.0Mpa, 1.6Mpa |

| 6. | Filtration precision: 10-300 mesh |

feature

1. Working temperature: ≤95℃;

3. Nominal diameter: DN15-DN600;

4. Nominal pressure: PN0.6-2.5Mpa;

5. Filtration precision: 50um-8000um

6. Shell material: Q235B, 304, 304, 316, 316L;

7. Sealing material: PTFE/rubber;

8. Inlet and outlet form: flange/inner wire/outer wire/quick installation

9. Cover pressure form: bolt/quick bolt

10. Applicable viscosity (cp): 1-30000

11. Mesh basket form: punching mesh/single-layer mesh/composite mesh

Different models for you to choose

Maintenance of the T-shaped basketfilter

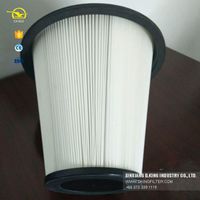

- The key component of this filter is the filter element. The filter element consists of a filter frame and a stainless steel wire mesh. SS wire mesh is a vulnerable part and needs special protection.

- After the filter works for a period of time, a certain amount of impurities will precipitate in the filter element, and then the pressure will increase and the flow rate will decrease, so the impurities in the filter element should be cleaned in time.

- When cleaning impurities, care should be taken to ensure that the stainless steel wire mesh in the filter element is not deformed or damaged. Otherwise, when you reuse the filter, the impurities in the filtrate will not meet the design requirements. And the compressor, pump or instrument will be destroyed.

- Once the stainless steel wire mesh is found to be deformed or damaged, it should be replaced immediately.

Packaging and Shipping

download Google

The order should be determined by the following parameters:

(1) What do you filter?

(2) diameter; working pressure;

(3) Filter material;

(4) flange standard; working pressure;

Pre-sales and after-sales service

pre-sale service

1.Your inquiry will be answered within 6 hours.

2.Help you choose the right model

3.Exactly designed to your requirements

After-sale service:

1. Provide 12 months warranty, you will always have our technical support

2. Engineering can serve your machine overseas

Frequently Asked Questions

1.Q: Can you provide us with detailed drawings?

Yes, we can provide you with drawings after advance payment.

2. Q: Are you a manufacturer or a trader?

We are a professional and experienced manufacturer located in Shanghai.

3.Q: Can you accept OEM?

Yes, we can produce machines exactly to your design standards.

4Q: How about the delivery time?

Usually 10-20 working days after prepayment, we promise we will ship as soon as possible.

contact us

-

5000ml vacuum suction filter glass filter device with Buchner funnel

-

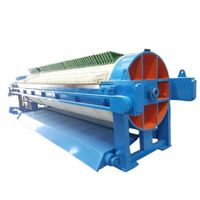

High quality rotary vacuum ceramic disc filter for water treatment and solid liquid separation

-

40 inch PP meltblown filter element for sediment high flow industrial water filter

-

Dryer with air compressor EMERSON Liquid Line Refrigerator Dryer with air compressor EK-084

-

High Efficiency Engine Parts Fuel Filter Factory 10289138 PU10008X SN70316 Manufacturer

-

Conical dust removal air filter 200900050 suitable for dust collector S26 with engineering plastic cover

-

Disposable capsules are available in a variety of sizes and with a variety of connectors for liquid and gas filtration

-

Best Selling High Performance Custom Color Replacement CLS112-10 CNG Natural Gas Filter

-

2.3-4 custom metal SS stainless steel perforated filter element (filter element) for process filtration

-

Pullman Ermator S Series Vacuum Dust Collector Conical Air Filter China Supplier

Other Products

-

$4000.00 - $4560.00 / set

$4000.00 - $4560.00 / set -

$9500.00 - $10000.00 / set

$9500.00 - $10000.00 / set -

$1.00 - $1.50 / piece

$1.00 - $1.50 / piece -

$1100.00 / set

$1100.00 / set