Textile dyeing machine 300 kg

-

Supplier: Taizhou Tongjiang Washing Machinery Factory -

Region: Jiangsu, China -

Contact: Ms Cherry Chen -

Price: $12000.00 / 1 - 2 pieces

$11000.00 / >=3 pieces -

Min. Order: 1 piece

| Packaging Details: | Veneer wooden box export standard packaging | Packaging Preview: | |

| Applicable industries: | Hotels, clothing stores, building materials stores, manufacturing plants, restaurants | Core Components Warranty: | 1 year |

| heating method: | indirect steam heating | Warranty: | 12 months |

| Health status: | new | Supply capacity: | 100 pieces per month |

| payment terms: | letter of credit, wire transfer | weight: | 300kg |

| brand: | Tong Yang | Mechanical test report: | if |

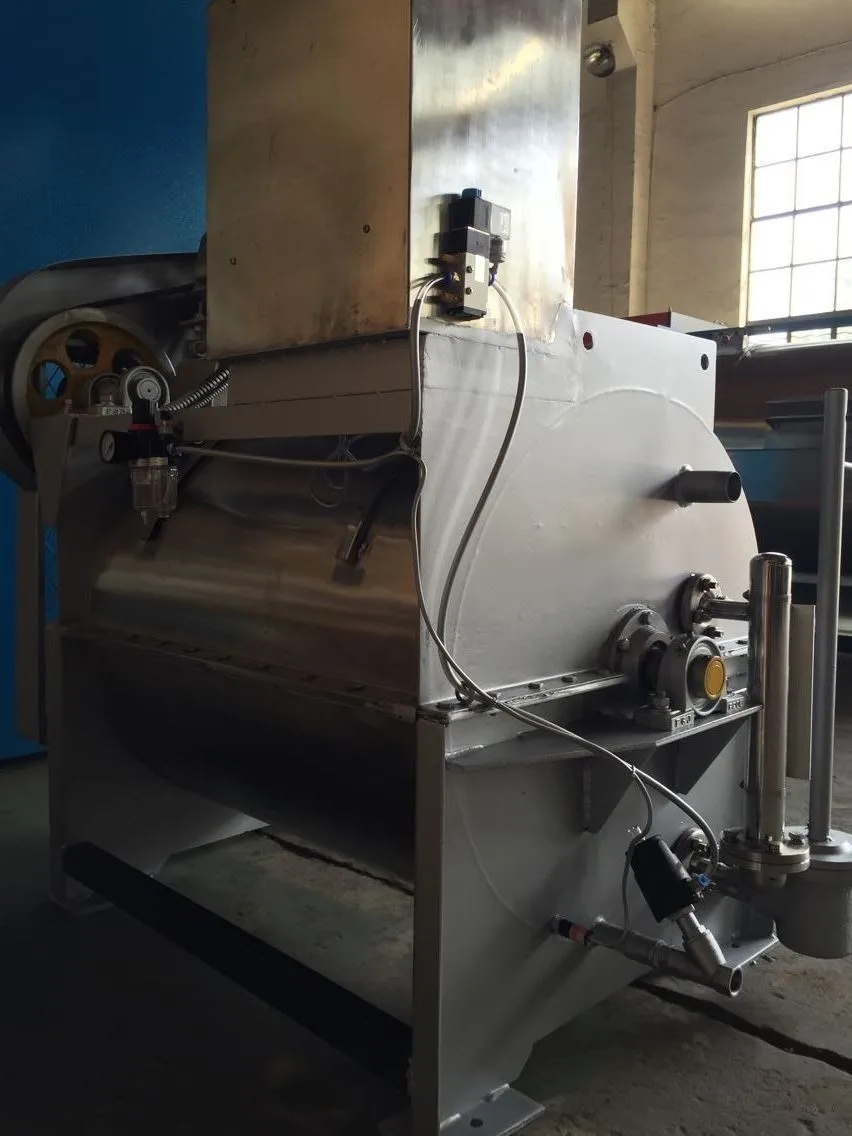

| Material: | 304 stainless steel | port: | Shanghai |

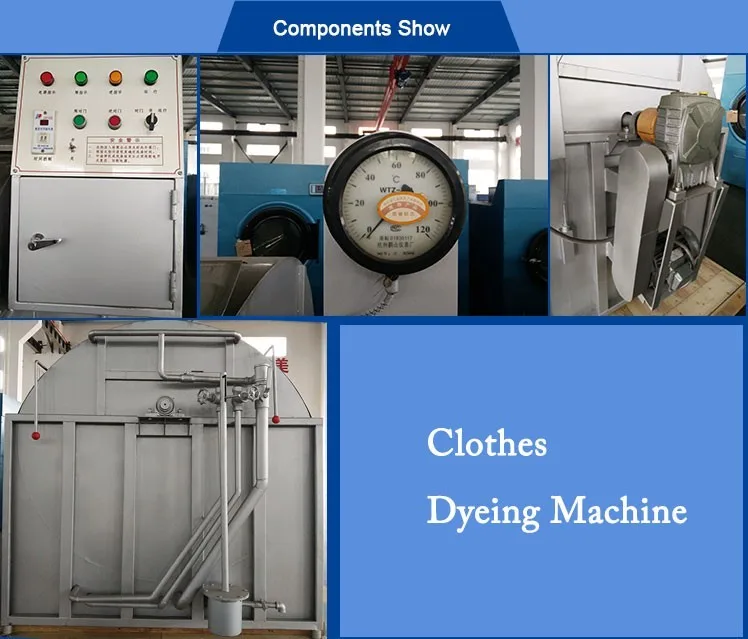

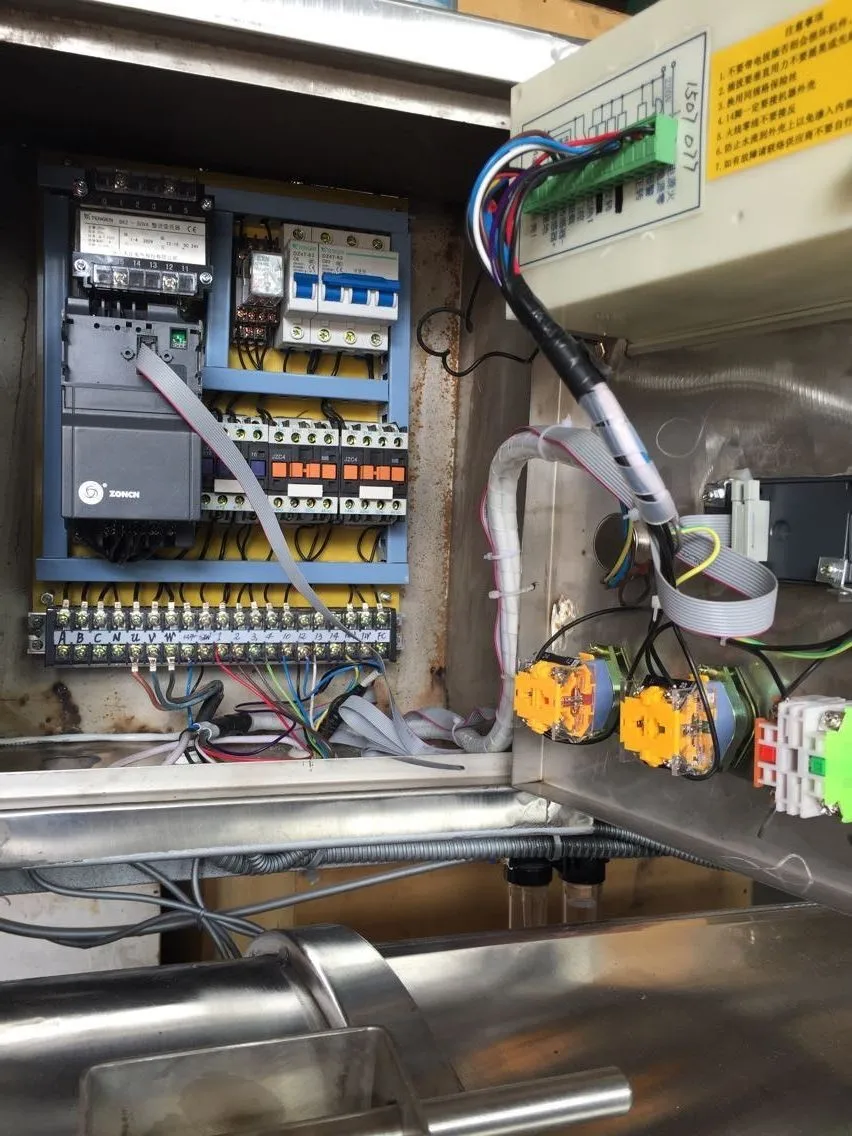

| Core components: | PLC, engine, bearing, motor, gear | Used for: | dyeing |

| capacity: | 15~400kg | Showroom location: | Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Vietnam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, Mexico, Russia, Spain, Thailand, Kenya, Argentina, South Korea, Chile, Colombia, Algeria , Sri Lanka, Romania, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Uzbekistan, Tajikistan, Malaysia, Australia, Morocco |

| Video external inspection: | if | place of origin; place of origin: | Jiangsu, China |

| Auto grade: | automatic | Name: | Textile dyeing machine |

| Marketing Type: | New Products 2020 | control: | computer control |

300kg textile dyeing machine:

Specification:

| type | maximum. capacity (Kilogram) |

drum size (mm) |

speed (rev/min) |

strength (kilowatt) |

Dimensions (mm) |

steam pressure (MPa) |

Water consumption per time (kg) |

| GXF30 | 30 | 660×800 | 5-33 | 1.1 | 1500×1100×1300 | 0.4-0.6 | 520 |

| GXF50 | 50 | 800×980 | 5-33 | 1.5 | 1750×1200×1500 | 0.4-0.6 | 620 |

| GXF70 | 70 | 950×1220 | 5-33 | 2.2 | 2050×1400×1850 | 0.4-0.6 | 750 |

| GXF100 | 100 | 960×1420 | 5-33 | 3 | 2300×1400×1850 | 0.4-0.6 | 920 |

| GXF150 | 150 | 1060×1650 | 5-33 | 4 | 2500×1500×1900 | 0.4-0.6 | 1100 |

| GXF200 | 200 | 1080×2000 | 5-33 | 5.5 | 2900×1500×2000 | 0.4-0.6 | 1430 |

describe:

1. This machine is suitable for wool, polyester, nylon, rayon, knitwear, etc. Dyeing process.

2. The liquid cylinder is made of high-quality contacts and high corrosion-resistant 202'' stainless steel plate, ensuring non-polluting fabric and durable.

3. The wall of the dyeing tank and the paddle wheel are all polished to ensure that the fabric is not damaged.

4. According to the dyeing requirements and severity of different fabrics, it can be carried out on any high-speed rotating paddle without electric device.

5. The dyeing process is all started and stopped by the button operation of the electric box, the dyeing time can be automatically controlled by the time, and the dyeing time can be adjusted in advance according to different needs.

6. Through the forward and reverse power automatic controller, the dyeing vat paddle wheel falls into the rotation range, and the liquid flow and fabric are changed, thereby improving the dyeing effect.

7. According to different dyeing process requirements, install direct or indirect steam pipes at the bottom of the tank to achieve the effect of heat preservation and heat preservation.

-

High temperature and high pressure medical material gauze bleaching machine

-

Tubular knitted fabric overfeed expander spreading machine

-

Polyester Dyeing Machine

-

DGNT Fine Fabric Dyeing Machine

-

Electric single-sided leather side dyeing machine semi-automatic belt side color painting box

-

High temperature sample staining machine (glycerol), laboratory staining machine

-

Normal temperature dyeing machine

-

High temperature and high pressure fiber dyeing machine

-

Steam-Heated Chain Ironing Machine

-

Best Quality Fabric Dyeing Machine / Industrial Washing Machine / Wool Washing Machine