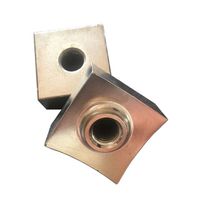

Hss Packaging Machine Knife Food Bag Packaging Serrated Blade Zigzag Cutting Knife For Packaging Machine

-

Supplier: Zhijing Precision Machinery (Shanghai) Co., Ltd. -

Region: Shanghai, China -

Contact: Ms Lily Duan -

Price: $2.00 /pair -

Min. Order: 1 pair

Product details

| Applicable industries: | Clothing Stores, Building Materials Stores, Manufacturing Plants, Machinery Repair Stores, Food and Beverage Plants, Farms, Restaurants, Retail, Food Stores, Printing Stores, Construction Engineering, Energy and Mining, Food and Beverage Stores, Advertising Agencies | type: | serrated knife |

| Mechanical test report: | if | port: | Shanghai |

| application: | paper processing machine | After Warranty Service: | Video technical support, online support, spare parts, on-site maintenance and repair services |

| Packaging Details: | All our products are carefully packaged. We will choose the right packing box for the product: foam box, carton, wooden box to protect the product from shipping damage | Custom order: | accepted |

| Local service location: | Peru, Mexico, Malaysia, South Korea, Sri Lanka, Ukraine | Certificate: | ISO9001 |

| Supply capacity: | 100 pairs per month | Marketing Type: | New Products 2020 |

| Core parts warranty: | 6 months | Key words: | serrated knife |

| Material: | M2, D2, SK5, or as needed | quality assurance: | We guarantee the high quality of our knives |

| place of origin; place of origin: | China | Advantage: | long working life |

| Core components: | Packaging machine blade | Video external inspection: | if |

| Health status: | new | payment terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram |

| Showroom location: | not any | brand: | Zhijing |

| size: | 175mm*17mm*5mm | product name: | Packing Serrated Saw Blades Serrated Knives |

| Warranty: | 6 months |

Product Description

Packaging and Delivery

In order to better protect the safety of your goods, we will provide professional, environmentally friendly, convenient and efficient packaging services.

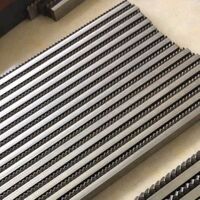

processing

Machining of serrated knives andbladefor packaging machines | ||

1. Select material | Select the right material for the processing of the product. Materials we have: 9CrSi, Cr12mov, W6Mo5Cr4V2, LD, H13, 9Mo2V, 60Si2Mo, 15GCr12, Cr12, 42CrMo, 55SiCr, DC53, 3Cr13, SK5, HSK-51, SKD-11, M2, D2, ASP30, ASP60, PM79, EM2 | |

2. Forging | Increase the density and hardness of the material Material | |

3. Annealing | It can quickly reduce the hardness of the material, which is convenient for fine Machined finishing. | |

4. Finishing | Process raw materials into suitable shapes. | |

5. Quenching | Increase the hardness of the molded product. | |

6. Insulation | In order to increase the wear resistance of the product, it is necessary to Insulated for a long time. | |

7. Initial grinding | Grinding product accuracy, gloss, parallelism, etc. | |

8. Precise grinding | Supergrinding improves precision and parallelism product | |

9. Quenching and tempering | Parallel quenching and tempering of products processing. | |

10. Quality Check | Reject substandard products from entering the market | |

11. Packaging | Choose the right packaging for the product. | |

VIEW MORE

You may like

-

43*22*0.2mm three-hole blade brand new gear motor bearing essential engine core component home manufacturing factory retail

-

British N95 mask machine mold / custom welding mold ultrasonic roller with LOGO mask machine roller industrial blade

-

Wear Resistant Dual Shaft Plastic Metal Shredder Blades For Waste Recycling Industry

-

Tungsten Carbide Digital Cutting Machine Blades For CNC Machine Zund Z10

-

105*70*1.2mm Circular Slitter Blade for High Speed Steel Industrial Cutting Machine Parts

-

Packaging machine toothed blade perforating blade

-

Single Shaft Waste Paper Shredder Cutting Blades and Cutters Single Shaft Shredder Blades

-

High Quality Shearing Knife Shearing Blade Packaging Serrated Blade Forming Serrated Knife

-

Customized High Quality Food Grade Stainless Steel Blade Shaped Mechanical Blades

-

Hot selling blade with spare parts foam sponge cutter with knife with cutting blade

Other Products

-

$2.00 / piece

$2.00 / piece -

$17.00 / piece

$17.00 / piece -

$50.00 / piece

$50.00 / piece -

$32.00 / piece

$32.00 / piece -

$29.00 / piece

$29.00 / piece -

$18.00 / piece

$18.00 / piece -

$45.00 / pair

$45.00 / pair