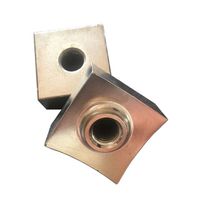

Wear Resistant Dual Shaft Plastic Metal Shredder Blades For Waste Recycling Industry

-

Supplier: Jiangsu Xinmechan Technology Co., Ltd. -

Region: Jiangsu, China -

Price: $119.00 / 1 - 19 sets

$98.00 / 20 - 99 sets

$78.00 / >=100 sets -

Min. Order: 1 set

Product details

| Health status: | new | treat: | heat treatment |

| Packaging Details: | wooden box | brand: | new machinery |

| Package preview: | size: | Various sizes available, customized | |

| Video shipment inspection: | if | Mechanical test report: | if |

| Module life: | 2-6 years old | Material: | H13, stainless steel, 9CrSi, 55SiCr or customized |

| port: | Shanghai Port | payment terms: | Western Union, D/P, D/A, T/T |

| Applicable industries: | Manufacturing plants, machine repair shops, household, energy and mining, other, advertising agencies, green recycling plants, environmental industries | Warranty: | 1.5 years |

| type: | Double Shaft Garbage Shredder | Showroom location: | the Philippines |

| Supply capacity: | 10000 blades per month | Plot format: | CAD, PDF AI PSD etc. |

| Marketing Type: | normal product | Processing: | Yes |

| application: | Universal Shredder Parts Knife | hardness: | 45-90HRC |

| Core component warranty: | 1 year | Core components: | Gearbox, motor, PLC |

Our shredder blades are designed for shredders that can process a wide variety of materials including paper, cardboard, plastic, rubber, tires, wood, e-waste, household waste lithium batteries and metals. Our blades are made of high-strength alloy or stainless steel, ensuring long-lasting cutting performance and durability.

size | custom made |

Material | H13, Cr12MoV, SKD-11, D2, 1.2379, high alloy tool steel |

hardness | 58-60 Hardness |

tolerant | Exceeds OEM specifications |

OEM service | usable |

Package | Wooden case, standard export packing |

application | Shredder blades for plastic, rubber, metal, waste recycling |

delivery time | 30 days after receiving the deposit |

feature:

1. High-strength alloy or stainless steel structure.

2. Precision cutting edge for efficient shredding.

3. Compatible with various types and models of paper shredders.

4. Easy to install and replace.

5. Competitive price for high quality products.

Whether you are a shredder manufacturer or user, our shredder blades provide superior cutting performance and durability for efficient and safe shredding operations. Please contact us for more information and custom options.

Welcome to our store, we specialize in manufacturing high quality paper shredder blades for worldwide customers. As a professional shredder blade manufacturer, we are committed to providing excellent products and services that meet our customers' needs.

Our state-of-the-art production facility is equipped with state-of-the-art machinery,Allows us to manufacture shredder blades in a variety of different sizes and configurations.We use only the highest quality materials, including premium tool steels and carbides, to ensure our blades meet the highest standards of durability and performance.

Our team of skilled technicians and engineers has extensive experience in the Shredder Blade industry and is dedicated to providing the best products and services. We work closely with our clients to understand their needs and requirements, and we stand ready to provide expert guidance and support.

In our company, we take quality very seriously. We have a comprehensive quality control system, and every blade that leaves our factory is rigorously tested and inspected to ensure it meets our stringent standards.We are committed to delivering products that exceed our customers' expectations and deliver long-lasting performance.

Our client base spans the globe, and we have developed strong relationships with clients in North America, Europe, Asia and beyond. We understand the importance of timely delivery and responsive customer service, and we are committed to providing an exceptional experience to all of our customers.

We are committed to providing our customers with quality after-sales service to ensure the best performance from your shredder blades.Our after-sales service includes:

product quality assurance | Regular maintenance |

We back all shredder blades with a warranty to ensure you get a free repair or replacement during the warranty period. | We recommend regular maintenance of your shredder blades to keep them in top condition. We provide professional maintenance services including blade sharpening, cleaning and lubrication. |

fast reaction | Customer Support |

Quick Response: We guarantee a timely response to your after-sales service request to ensure your equipment returns to normal operation as soon as possible. | CUSTOMER SUPPORT: Our customer support team is here to help and advise you, making sure you can use and maintain your shredder blades with ease. |

No matter what problems you encounter, we will do our best to provide you with fast, efficient and professional after-sales service, so that you can use our products with peace of mind.

Q: What are the commonly used materials for making shredder blades?

A: Shredder blades are usually made of high quality tool steel such asD2, M2 or H13, and alloy steels such as 4140 or 4340.Some manufacturers also use carbide and other hard materials to improve the durability and performance of the blade.

Q: How long do shredder blades typically last?

A: The lifespan of a shredder blade will vary depending on the material being shredded, how often it is used, and other factors. Generally, a high-quality shredder blade will last anywhere from a few months to a few years before needing to be replaced.

Q: How do I know when to replace the shredder blades?

A: Signs that your shredder blade may need replacing include decreased cutting performance, increased noise and vibration during operation, and obvious signs of wear or damage to the blade itself.

Q: Can shredder blades be sharpened or repaired?

A: In some cases, shredder blades can be sharpened or repaired to prolong their life. However, this depends on the extent of the damage and the type of blade material. It's best to consult a professional blade sharpening or repair service to determine if your blade is salvageable.

Q: Are there different types of shredder blades for different applications?

A: Yes, there are many different types of shredder blades available, each designed for a specific application and material. Some common types of shredder blades include single-, dual-, and quad-shaft blades, as well as various tooth and hook configurations.

Q: How do I choose the right shredder blade for my application?

A: To choose the right shredder blade for your application, you need to consider factors such as the type and hardness of the material being shredded, the size and consistency of the shred required, and the desired throughput. It is also important to consult a knowledgeable blade manufacturer or supplier who can recommend the best blade for your specific needs.

Q: Can I order custom shredder blades?

A: Yes, many blade manufacturers offer custom shredder blades to meet specific customer requirements. This may involve designing inserts with specific tooth profiles, edge geometries or other features to optimize performance for a particular application.

VIEW MORE

You may like

-

43*22*0.2mm three-hole blade brand new gear motor bearing essential engine core component home manufacturing factory retail

-

British N95 mask machine mold / custom welding mold ultrasonic roller with LOGO mask machine roller industrial blade

-

Tungsten Carbide Digital Cutting Machine Blades For CNC Machine Zund Z10

-

105*70*1.2mm Circular Slitter Blade for High Speed Steel Industrial Cutting Machine Parts

-

Packaging machine toothed blade perforating blade

-

Single Shaft Waste Paper Shredder Cutting Blades and Cutters Single Shaft Shredder Blades

-

High Quality Shearing Knife Shearing Blade Packaging Serrated Blade Forming Serrated Knife

-

Customized High Quality Food Grade Stainless Steel Blade Shaped Mechanical Blades

-

Hot selling blade with spare parts foam sponge cutter with knife with cutting blade

-

Flannel Cutting Circular Blade Convenient and Fast Cloth Cutting Circular Blade

Other Products

-

$6.00 - $38.00 / piece

$6.00 - $38.00 / piece -

$6.00 - $38.00 / piece

$6.00 - $38.00 / piece