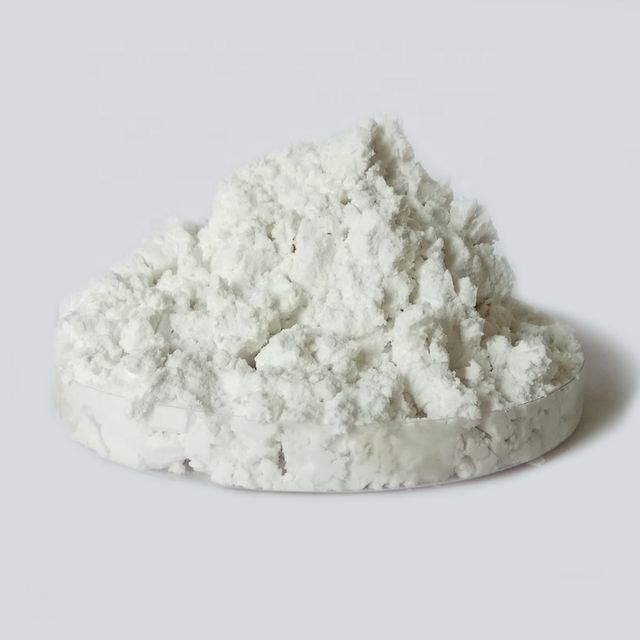

Diatomite filter aid for beer industry DE filter media for beer filtration

-

Supplier: Shengzhou Huali Diatomite Products Co., Ltd. -

Region: Zhejiang, China -

Price: $600.00 / >=1000 kilograms -

Min. Order: 1000 kilograms

| Moisture: | 0.5 | Silica: | 90.8 |

| Supply capacity: | 1000 metric tons per month | use: | beer industry |

| diatomite: | diatomite | use: | filter aid |

| port: | Shanghai or Ningbo | Applicable industries: | Food and Beverage Factory |

| Packaging Details: | 25kg/woven bag | payment terms: | wire transfer |

| Penetration: | 1.5-3.5 | brand: | Feifei |

| Median particle size: | twenty four | pH: | 10.0 |

| color: | white | diatomite: | diatomite |

| place of origin; place of origin: | Zhejiang, China |

Diatomite/Diatomite Beer Industry Filter Aid Beer Filtration DE Filter Media

Solid-liquid separation or solid-liquid separation (SLS) is one of the most widely used operations in industrial processing. Depending on the final product, the required material can be liquid or solid.

Diatomaceous earth filter aids are lightweight, chemically inert, and form a high porosity filter cake to maintain free flow of liquids. Specifically, an efficient filter aid has the following characteristics:

- The particles must be structured so that they do not pack tightly together, but form a cake with 85% to 95% pore space. This not only allows for higher initial flow rates, but also provides pore space to capture and contain filterable solids, while leaving a high percentage of channels open for flow.

Use of diatomaceous earth filter aid:

1. Condiments: monosodium glutamate, soybean, vinegar, salad oil, rapeseed oil, etc.

2. Beverages: beer, rat fee, rice wine, fruit juice, wine, syrup drinks, etc.

3. Medicine: antibiotics, vitamins, Chinese medicine refining, dental fillings, cosmetics, etc.

4. Chemical products: organic acid, inorganic acid, alkyd, paint, vinyl resin, etc.

5. Industrial oil products: lubricating oil, lubricating oil additives, petroleum additives, metal flake oil, transformer oil, coal tar, etc.

6. Water treatment: daily waste water, industrial waste water, effluent treatment, swimming pool water, etc.

7. Sugar industry: fructose syrup, glucose, starch sugar, sucrose, etc.

Application Instructions:

- preliminary inspection: Visually inspect filter elements (especially in spring) as torn or improperly installed elements or fabric can cause problems, while dirty or clogged elements can reduce water flow and result in short cycles.

- pre-painted: This procedure is used to apply a thin layer of DE to the filter element.

- Mix the appropriate amount of CD080 filter aid (depending on package instructions and filter manufacturer's instructions) with water in a bucket to form a slurry.

- Apply directly to the pool skimmer.

- Backwashing and cleaning: Backwashing DE filters involves reverse flow and/or manual flushing of filter elements. Proper maintenance and thorough cleaning of the filter is necessary for good filtration.

Flux Calcined Diatomite Filter Aid

CD 090

physical properties

color | white |

Penetration (Darcy) | 3.5-5.0 |

Sieve Analysis +150 mesh sieve residue% +325 mesh residue% |

45 |

Density (g/ml) wet bulk dry goods |

240 |

Median particle size (microns) | 35 |

PH value (10% slurry) | 10.0 |

Moisture (%) | 0.5 |

proportion | 2.3 |

Acid Solubility% | ≤3.0 |

Water solubility % | ≤0.5 |

chemical properties

Lead (lead), ppm | 4.0 |

Arsenic (As), ppm | 5.0 |

Silica % | 90.3 |

Al2O3 % | 4.0 |

Fe2O3 % | 1.5 |

Calcium Oxide % | 0.4 |

Magnesium oxide % | 0.5 |

Other oxides % | 3.0 |

Ignition Loss % | 0.5 |

-

Medium Filter / Industrial Filter Aid / Food Grade Pulp

-

Oil cellulose filter aid manufacturers manufacturers directly supply beer food industry beverage cellulose fiber

-

Organic filter aid / cellulose filter / filter aid

-

flux calcined diatomaceous earth filter aid

-

kieselguhr filter aid for edible oil filtration food grade filter aid

-

High Quality ultrastrong Cellulose Fiber for filtering

-

Kieselguhr Filter Aid (QH-500#)

-

diatomaceous earth powder food grade

-

Full Auto Filter-Press Plant

Other Products

-

$680.00 / metric ton

$680.00 / metric ton -

$680.00 / metric ton

$680.00 / metric ton -

$680.00 / metric ton

$680.00 / metric ton