kieselguhr filter aid for edible oil filtration food grade filter aid

-

Supplier: Shengzhou Huali Diatomite Products Co., Ltd. -

Region: Zhejiang, China -

Price: $680.00 /metric ton -

Min. Order: 1 metric ton

| Loss on Ignition: | 0.5%; | Place of Origin: | Zhejiang China; |

| Material: | Celite Diatomaceous Earth Powder; | Density: | 0.3g/ml; |

| pH: | 10.0; | Supply Ability: | 1000 Metric Ton/Metric Tons per Month; |

| Median Particle Diameter: | 24um; | Packaging Detail: | Usually in pp woven bags of 25kg/20kg net each, with pallets. Jumbo bags are also available. 25kgs per bag, or Jumbo Bag of 500kg net each , on wooden pallet. Customized packaging is available.; |

| Payment Terms: | L/C,T/T; | Port: | Shanghai or Ningbo; |

| Permeability: | 3.5-5.0 darcy; | colour: | white; |

| SiO2: | 90.8%; | Brand Name: | FeiFei; |

| Product Name: | kieselguhr filter aid; | Moisture: | 0.5%; |

diatomite / diatomaceous earth / kieselguhr filter aid for edible oil filtration food grade DE filter media

Diatomaceous earth filtration is a key process step in reliable and consistent production of vegetable oils, edible oils, and related food products .

Diatomaceous earth filter aids are light in weight, chemically inert, and form high porosity filter cakes to maintain free-flow of the liquid. Specifically, an efficient filter aid is characterized by the following:

The structure of the particles must be such that they will not pack together closely, but will form cakes that are 85% to 95% pore space. This not only permits higher initial flow rates, but also provides pore spaces to trap and contain the filterable solids while leaving a high percentage of channels open for flow.

diatomaceous earth filter aid for edible oil filtration

Potential applications for mineral precoat filtration in edible oil purification include:

- removal of triglycerides and particulate matter (“foots”) from crude oil

- miscella filtration for production of lecithin from gums

- removal of bleaching earth, color bodies, and other components from bleached and/or detoxified oils

- removal of waxes to enhance cold stability of winterized oils

- removal of nickel catalyst after hydrogenation

- residual catalyst filtration to remove solid nickel catalyst after transitioning to nickel soaps

- removal of impurities formed during deodorization

- polishing filtration to improve product quality and clarity

The separation of solids from liquids, or Solid-Liquid-Separation (SLS) is one of the most widely used operations in industrial processing. The desired material may be either the liquid or the solid, depending on the finished product.

Diatomaceous earth filter aid for edible oil filtration

Diatomaceous earth filter aids are light in weight, chemically inert, and form high porosity filter cakes to maintain free-flow of the liquid. Specifically, an efficient filter aid is characterized by the following:

- The structure of the particles must be such that they will not pack together closely, but will form cakes that are 85% to 95% pore space. This not only permits higher initial flow rates, but also provides pore spaces to trap and contain the filterable solids while leaving a high percentage of channels open for flow.

- Diatomaceous earth filter aid for edible oil filtration

As tighter and tighter restrictions are enacted on discharged water from industrial plants due to environmental concerns, there is a growing need for more effective industrial wastewater treatment methods.

Two key components of these treatment methods are mechanical (physical) separation and sludge dewatering. The clarified water can then be recycled back into the manufacturing process or discharged safely.

Using of diatomite filter aids:

1. Condiment: monosodium glutamate, soy, vinegar, salad oil, colza oil, etc.

2. Beverage: beer, rat fee, yellow wine, fruit juice, wine, beverage syrupy, etc.

3. Pharmaceutical: antibiotic, vitamin, refined traditional Chinese medicine, filling for dentistry, cosmetics, etc.

4. Chemical products: organic acid, mineral acid, alkyd, oil paint, vinylite, etc.

5. Industrial oil products: lubricating oil, additives of lubricating oil, petroleum additive, trussed metal sheet oil, transformer oil, coal tar, etc.

6. Water treatment: daily waste water, industrial waste water, effluent treatment, swimming pool water, etc.

7. Sugar Industry: fruit syrup, glucose, starch sugar, sucrose, etc.

Application Instructions:

- Preliminary Inspection: Visually inspect the filter elements (particularly in the springtime) as torn or improperly fitted elements or fabric acan cause problems, and dirty or clogged elements will reduce the flow of water as well as cause short cycles.

- Precoat: This procedure is used to coat or cake the filter elements with a thin layer of DE

- Thoroughly mix the proper amount of CD080 filter aid (depending on package instructions and filter manufacturer instructions) in a bucket with water to form a slurry.

- Apply directly to pool's skimmer.

3. Backwashing & Cleaning: Backwashing the DE filter involves reversing the flow and/or hand rinsing the filter elements. Proper maintenance and thorough cleaning of the filter are necessary for obtaing good filtration results.

Technical Data

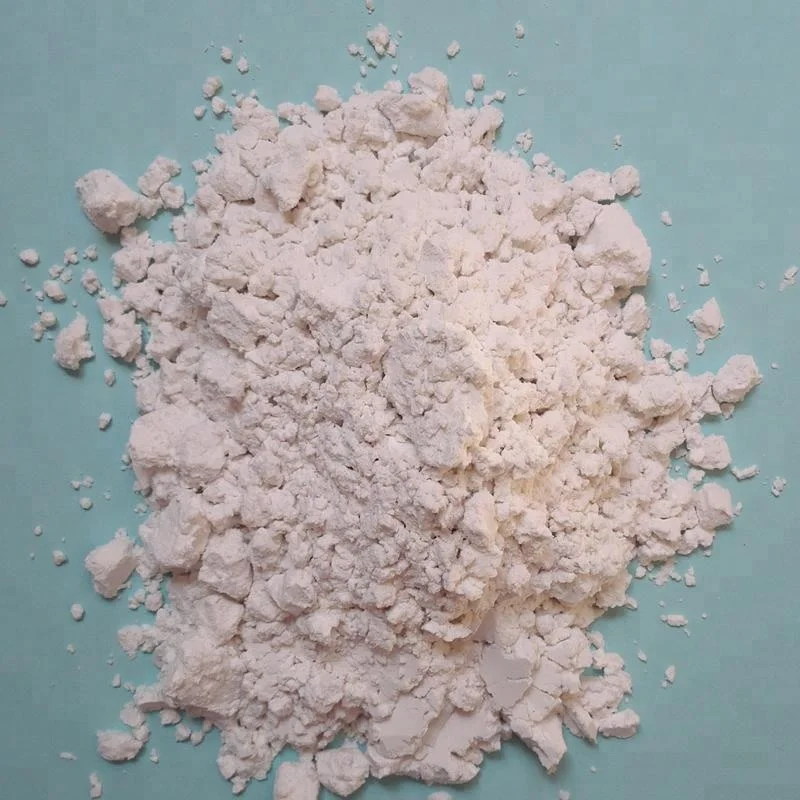

Flux Calcined Diatomaceous Earth Filter Aid

CD 090

Physical Properties

Color | White |

Permeability(Darcy) | 3.5-5.0 |

Sieve Analysis +150 Mesh Screen Residue % +325 Mesh Screen Residue % |

45 |

Density (g/ml) Wet bulk Dry bulk |

240 |

Median particle Diameter(microns) | 35 |

PH (10% slurry) | 10.0 |

Moisture (%) | 0.5 |

Specific gravity | 2.3 |

Acid Solubility % | ≤3.0 |

Water Solubility % | ≤0.5 |

Chemical Properties

Pb (lead), ppm | 4.0 |

Arsenic (As), ppm | 5.0 |

SiO2 % | 90.3 |

Al2O3 % | 4.0 |

Fe2O3 % | 1.5 |

CaO % | 0.4 |

MgO % | 0.5 |

Other Oxides % | 3.0 |

Loss on Ignition % | 0.5 |

Usually in pp woven bags of 25kg/20kg net each, with pallets. Jumbo bags are also available.

25kgs per bag, or Jumbo Bag of 500kg net each , on wooden pallet. Customized packaging is available.

samples are available, freight prepaid or freight collect.

Shengzhou Huali Diatomite Products Co., Ltd., a company (manufacturer) with a history of nearly 50 years, specializes in the production of diatomite, with a total investment of 20 million Yuan, and 30,000-square-meter factory area. Our company is provided with advanced air-drying equipment, rotary calciner and kiln, ultrafine crusher, classification process equipment, and perfect quality detection device. We annually produce 20,000 tons diatomite of CD series products under "Feifei" trademark. With good quality diatomite, advanced production equipment, strict quality control system, excellent technical and customer service, we can provide our clients with high-quality products and good service.

Shengzhou Huali Diatomite Products Co., Ltd

Add.: Bainidun Industrial Agglomeration Area, Ganlin Town, Shengzhou City, Zhejiang Province, China

URL:http://www.diatomite.co http://cndiatomite.en.alibaba.com

Tel: 0086 575 8361 8811

Fax: 0086 575 8361 7766

1. Q: What's the minimum quantity / MOQ?

A: 1MT, one full 20 feet container is better.

2. Q: What is the payment term?

A: 30% of payment by T/T in advance as deposit; The balance 70% of payment by T/T before Shipment.

3. Q: What is the earliest shipping time?

A: For normal packing, usually in 3 weeks after we receive the deposit , for special packing or customized packing , we will arrange asap.

4. Q: What is the packaging style ?

A: Normal packaging is In pp woven bags of 25kg/20kg net each.

5. Q: How can I get sample? / Is sample available ?

A: Sample is available and free, but you need to pay the freight cost.

-

Medium Filter / Industrial Filter Aid / Food Grade Pulp

-

Oil cellulose filter aid manufacturers manufacturers directly supply beer food industry beverage cellulose fiber

-

Organic filter aid / cellulose filter / filter aid

-

Diatomite filter aid for beer industry DE filter media for beer filtration

-

flux calcined diatomaceous earth filter aid

-

High Quality ultrastrong Cellulose Fiber for filtering

-

Kieselguhr Filter Aid (QH-500#)

-

diatomaceous earth powder food grade

-

Full Auto Filter-Press Plant

Other Products

-

$600.00 / kilogram

$600.00 / kilogram -

$680.00 / metric ton

$680.00 / metric ton -

$680.00 / metric ton

$680.00 / metric ton