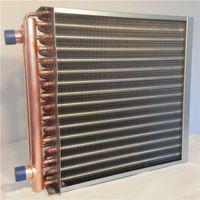

High quality water heat exchanger air with copper fan

-

Supplier: Changzhou Vrcoolertech Refrigeration Co., Ltd. -

Region: Jiangsu, China -

Contact: Mr Kevin Yuan -

Price: $116.00 / 1 - 49 units

$92.00 / >=50 units -

Min. Order: 1 unit

Product details

| Dimensions (L*W*H): | design | Tube type: | Smooth |

| Video external inspection: | if | Liquid flow rate: | 0.1~10M/s |

| The original: | Jiangsu, China | Tube: | copper |

| brand: | cooler | Main selling point: | long lasting |

| weight: | 5kg | Core Components Warranty: | 1 year |

| Fin surface: | bare | Fin material: | aluminum |

| Gross weight per piece: | 45.000 kg | type: | tube fin |

| Mechanical test report: | if | Packaging Details: | wooden packaging |

| Fin Type: | corrugated | place of origin; place of origin: | Jiangsu, China |

| Frame Material: | Galvanized steel | Marketing Type: | Hot Products of 2019 |

| Sales unit: | single product | application: | boiler |

| Showroom location: | Indonesia | Core components: | heat exchanger |

| Applicable industries: | Hotels, Clothing Stores, Building Materials Stores, Mechanical Repair Stores, Manufacturing Plants, Food and Beverage Plants, Farms, Restaurants, Home Use, Retail, Food Stores, Printing Stores, Construction Works, Energy and Mining, Food and Beverage Stores, Advertising Agencies | Voltage: | 220v/380v/custom |

| Warranty: | 1 year | Health status: | new |

| Maximum working pressure: | 40bar | product name: | Air to water heat exchanger with fan |

| structure: | tubular heat exchanger | Single package size: | 35X35X12 cm |

Product Description

1.Applications

A heat exchanger is an energy-saving device that transfers heat between two or more fluids at different temperatures. It transfers heat from a higher temperature fluid to a lower temperature fluid, bringing the fluid temperature to flow. Meeting the specified indicators of process conditions is also one of the main equipment for improving energy efficiency. ·Mainly concentrated in petroleum, chemical industry, metallurgy, electric power, shipbuilding, central heating, refrigeration and air conditioning, machinery, food, medicine and other fields. ·Our factory is currently focusing on large heat exchangers in various industries.2.raw material

tube | copper | titanium | aluminum | Carbon steel |

Stainless Steel 304 | Stainless Steel 316 | Copper Nickel (90/10) | Copper Nickel (70/30) | |

fin | copper | aluminum | Stainless steel | |

Carbon steel | titanium | |||

frame | Galvanized | aluminum | Stainless steel |

Material Details

tube

We manufacture pipes of different diameters, more thicknesses and different materials such as copper, stainless steel and cupronickel. During the flaring stage, the tube expansion allows perfect contact between the tube and the fins, so it ensures an efficient heat exchange.

COPPER - Copper Pipe

Stainless Steel - AISI 316L Tube

CURONICKEL - CuNi10Fe1Mn Tube

fin

The fins are made of aluminium, pre-painted aluminium or copper and are pressed with special corrugations that increase the heat exchange between the air and the fins, reducing load losses on the air side while promoting condensation or flowing thawed water. The fins can also be made of 316L stainless steel for installations where the heat exchange is in corrosive environments, such as those used in the food industry or in salty environments. The main geometries achievable depending on the material selected are reported below; in addition, larger or smaller spacings between the fins can be created depending on the application selected by the customer and the thickness of the tape required.

Aluminum fins

Hydrophilic aluminum fins

Pre-coated aluminum fins

Steel fins 316L

copper fins

plate

Thanks to its precise three-dimensional design and modern punching and CNC bending machines, it is possible to manufacture woodwork and structures in different sizes to suit any architectural requirements of the client.

Galvanized steel

aluminum plate

copper plate

brass plate

Stainless steel sheet Aisi 304 plated with protective pvc

Engineering data

We have customized products for many clients, here are some of the projects we have done before.We can provide design data and production drawings.

We promise we usedesign softwareSold by famous peopleEuropean HAVC softwarecompany. Through 8 years of cooperation with them, we have designed, processed and exported dry coolers to countries all over the world.All customer feedback is that the actual cooling performance is almost the same as the theoretical design value.

customer feedback photos

Russia Epoxy Coating Project

Thailand chiller project

New Zealand Heat Pump Project Golden Fin Evaporator

Italian 7mm fan coil unit coil

British Blygold Project

Australian U-coil project

VIEW MORE

You may like

-

AH0608T-CA Centrifugal Server Power Supply for Cooling Oil Fan Grid Fan

-

Best price competitive price tube heat exchanger swimming pool water heat exchanger

-

Custom Refrigerator Heat Exchanger Display Case/Freezer Micro Channel Heat Exchanger

-

Double-wall copper tube coaxial heat exchanger

-

Standard 24*24" air to water heat exchanger for room heating

-

Stainless steel tube heat exchanger, industrial shell and tube heat exchanger

-

OD 12.7mm - 50mm Food/Beverage Plant Coaxial Tube Heat Exchanger

-

Copper tube aluminum fin condenser with fan

-

Stainless steel crystal cooler manufacturer cooling coil

-

VT10 Titanium Stainless Steel Plate Industry for Plate Heat Exchanger with Gasket

Other Products

-

$16.80 - $42.70 / piece

$16.80 - $42.70 / piece -

$1480.00 - $2000.00 / unit

$1480.00 - $2000.00 / unit -

$860.00 / unit

$860.00 / unit -

$5.00 / unit

$5.00 / unit -

$10.00 / unit

$10.00 / unit

Related Search

high quality infrared heating lamp 500w

heat exchanger air

high quality car heated seats

water air heat exchanger core

water to air heat exchanger

elephant chain hoist with high quality

automatic gypsum powder equipment with high quality

best price with high qualiti ku lnb suppliers

high quality snap hook with key ring

high quality stable air compressor