Helmet Safety Hat Food Container Lunch Box Servo Motor 4 Color Pad Printing Machine with Independent Print Head

-

Supplier: Dongguan Hoystar Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Jenny Fong -

Price: $8900.00 /set -

Min. Order: 1 set

Product details

| Mechanical test report: | if | Auto grade: | automatic |

| Dimensions (L*W*H): | 1400*1000*1650mm | Voltage: | 220v |

| Colors and Pages: | Polychromatic | Core components: | PLC, Engine, Bearing, Gearbox, Motor, Pressure Vessel, Gear, Pump, Servo Motor 4 Color Helmet Pad Printing Machine |

| Packaging Details: | Wooden box packaging servo motor 4-color pad printing machine helmet safety helmet food container lunch box independent print head | Certification: | ce |

| Marketing Type: | New Products 2020 | Plate type: | Toppan Printing |

| usage: | Paper Printer, Label Printer, Card Printer, Tube Printer, Receipt Printer, Cloth Printer, Servo Motor 4 Color Pad Printer For Helmet Hard Hat Food Container Lunch Box With Separate Print Head | Health status: | new |

| payment terms: | L/C,Western Union,T/T,MoneyGram | Main selling point: | high accuracy |

| Warranty: | 1 year | Packaging Preview: | |

| After-sales service provided: | Online support | type: | 4 color pad printing machine for helmet hard hat food container, pad printing machine |

| place of origin; place of origin: | Guangdong, China | After Warranty Service: | Video technical support |

| weight: | 170kg | Applicable industries: | Clothing Stores, Manufacturing Plants, Machinery Repair Shops, Food and Beverage Plants, Retail, Printing Stores, Advertising Agencies, Helmet Servo Motor Four Color Pad Printing Machines |

| port: | can choose | Supply capacity: | 110 sets per month |

| brand: | good star | Showroom location: | Mexico |

| Core Components Warranty: | 1 year | Video external inspection: | if |

Product Description

Helmet Safety Hat Food Container Lunch Box Servo Motor 4 Color Pad Printing Machine with Independent Print Head

Features

1. PLC program, a variety of print mode options

2. Built-in automatic 4-digit counter and statistics. number of prints

3. Servo positioning without mechanical adjustment

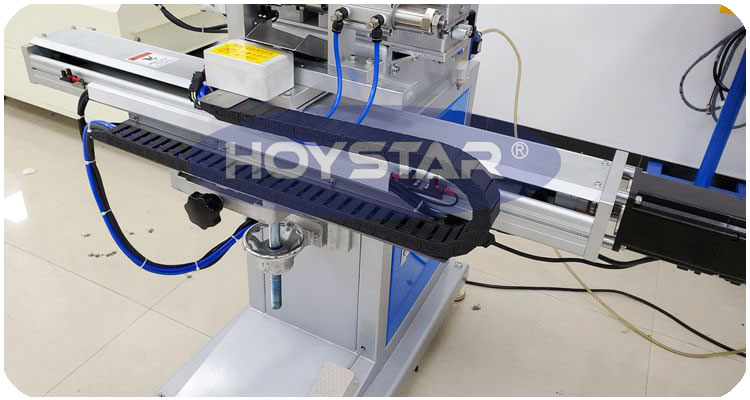

4. Using Japanese THK linear guide and ball screw to build linear table

5. Each nozzle can be lifted up and down independently, not limited by the size of the product

6. The body is made of coin alloy with metal coating surface

7. The XYZ direction of the worktable, print head and ink tray can be adjusted

8. Ink suction and pad printing pressure can be adjusted independently

9. The stroke of the scraper is adjustable

10. It has the function of automatically sliding and leveling the ink before and after to avoid partial solidification of the ink.

11. All cylinder speeds have independent regulator intortum

12. Using original Japanese SMC and Taiwan Airtic pneumatic components

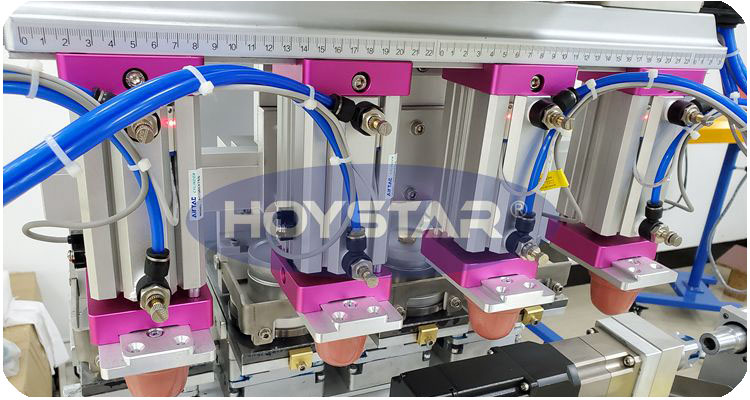

13. Each adjustable position has a scale mark

14. It has the function of preventing the mat from falling when there is no air pressure in

15. The machine runs fast, the sound is stable and the sound is low.

1. PLC program, a variety of print mode options

2. Built-in automatic 4-digit counter and statistics. number of prints

3. Servo positioning without mechanical adjustment

4. Using Japanese THK linear guide and ball screw to build linear table

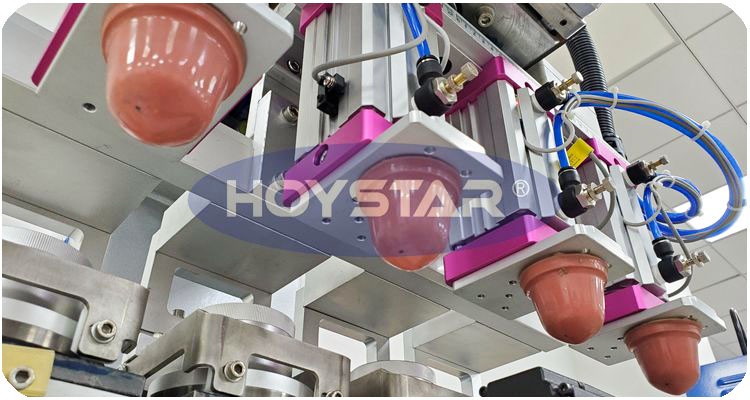

5. Each nozzle can be lifted up and down independently, not limited by the size of the product

6. The body is made of coin alloy with metal coating surface

7. The XYZ direction of the worktable, print head and ink tray can be adjusted

8. Ink suction and pad printing pressure can be adjusted independently

9. The stroke of the scraper is adjustable

10. It has the function of automatically sliding and leveling the ink before and after to avoid partial solidification of the ink.

11. All cylinder speeds have independent regulator intortum

12. Using original Japanese SMC and Taiwan Airtic pneumatic components

13. Each adjustable position has a scale mark

14. It has the function of preventing the mat from falling when there is no air pressure in

15. The machine runs fast, the sound is stable and the sound is low.

technical parameter

Steel plate size | 100*250mm |

Closed Ink Cup Diameter | 90mm |

Maximum printing area | Diameter 90mm |

air pressure | 5-7 bars |

Voltage | 220V or 110V single phase |

aspect | 1140*900*1650mm |

weight | 150kg |

detailed picture

independent print head,

Cylinder drive and printing are controlled separately

Adopt PLC program and touch screen control panel

Closed Ink Cup System

Has the advantages of saving ink cost and environmental protection

feature

1. Action model options fully automatic semi-automatic manual self-programming

2. (You can choose to print 1, 2, 3, 4 colors and print in any rotation

3. Working mode 1-4 stations can be positioned arbitrarily

4. Start mode panel foot switch

5. Fixed pulse positioning of shuttle and turntable

6. Driving mode of shuttle and turntable servo motor

7. Electronic switch for scraper working mode

8. Scraper pressure controller through pressure regulating valve

2. (You can choose to print 1, 2, 3, 4 colors and print in any rotation

3. Working mode 1-4 stations can be positioned arbitrarily

4. Start mode panel foot switch

5. Fixed pulse positioning of shuttle and turntable

6. Driving mode of shuttle and turntable servo motor

7. Electronic switch for scraper working mode

8. Scraper pressure controller through pressure regulating valve

Silicone pad, adjustable front and rear

Shuttle table operation/servo motor and rail drive

Printing sample display

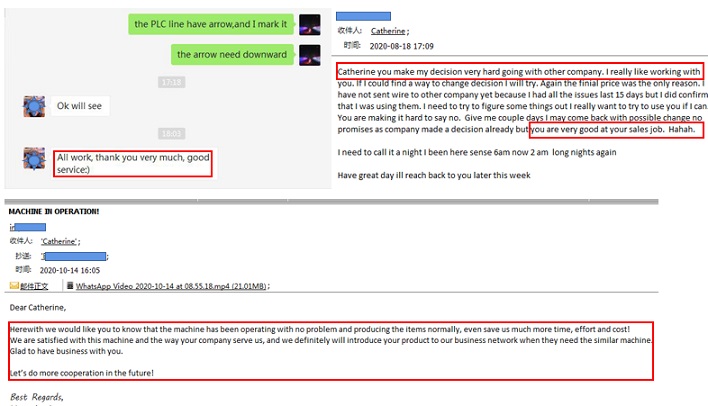

customer feedback

VIEW MORE

You may like

-

Eight-color plastic toy full body printing pattern machine toy automatic pad printing machine

-

Two-color ceramic tile printing machine/pan ceramic pad printing

-

Buffer Printer Odorless Pad Printing Machine Sealed Ink Cup Toy Card Pad Printing Machine

-

Automatic Electric Pad Printer

-

Small manual one-color pad printing machine is easy to operate

-

Electric Pneumatic Ink Cup Manual Pad Printer Electric Pad Printer

-

Desktop Mimeograph Machine Pneumatic Cup Small Helmet Pad Printing Machine

-

Manual pad printing with new sealed electric ink

-

Semi Automatic Easy IC Steel Plate Free Shipping Silicone Glass Bottle Pad Printer 2 Colors Conveyor Belt Dryer

-

4 color pad printing pad printing machine silicone seal ink cup pad printing machine with conveyor belt

Other Products

-

$5500.00 - $7500.00 / set

$5500.00 - $7500.00 / set -

$4800.00 / set

$4800.00 / set -

$4800.00 / set

$4800.00 / set -

$8000.00 / set

$8000.00 / set -

$14500.00 / set

$14500.00 / set -

$1000.00 / set

$1000.00 / set