Simple operation plastic melter densifier agglomerator plastic

-

Supplier: Suzhou Beakeland Machinery Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Bonnie Wang -

Price: $4000.00 /set -

Min. Order: 1 set

Product details

| Applicable materials: | PP PE PET PS film bag fiber woven non-woven fabric, etc.; | Control System: | star triangle; |

| Weight (kg): | 2000; | Material to Material Contact: | SUS304 stainless steel; |

| Video external inspection: | if; | Packaging Details: | FCL Shipping: Nude Color Packing, Free Packing with Plastic Stretch Film Only. LCL: Packed in wooden case. If the customer needs wooden box packaging or other special packaging types, the packaging fee needs to be paid by the customer. |

| Applicable industries: | Manufacturing plants, plastic recycling plants; | Bearing Lubrication Type: | Hydraulic oil does not stop for lubrication; |

| Marketing Type: | normal product; | Final product: | bubble particles; |

| Core components: | PLC, engine, bearing, gearbox, motor, pressure vessel, gear, pump; | Supply capacity: | 10 sets per month; |

| Plastic Type: | Bopp,PE,PP/PE,EPS,PP,PET,PETG,PA; | brand: | BKL; |

| product name: | plastic melter densifier agglomerator plastic; | Mechanical test report: | if; |

| port: | Shanghai; | Dimensions (L*W*H): | 2.7*1*1.85; |

| Main selling point: | multifunctional; | Showroom location: | Brazil; |

| Warranty: | 1 year; | Outlet method: | By pneumatic or manual; |

| place of origin; place of origin: | Jiangsu, China; | Packaging Preview: | ; |

| Core Components Warranty: | 1 year; | Working principle: | Self-friction heating and plasticizing; |

| payment terms: | L/C,Western Union,T/T,MoneyGram; | Health status: | new; |

| spinning speed: | 750 rpm; |

Product Description

phosphorusPlastic melt densifier,agglomerator plastic

feature:

The granulator can directly recycle waste plastic films and other products with a wall thickness of less than 2mm into granules. It is suitable for the agglomeration of waste products or films made of soft PVC, HDPE, LDPE, PP and other thermoplastics.

The pellets can be used directly in an extruder or injection molding machine. It can also be further granulated according to some advanced requirements.

The granulator can directly recycle waste plastic films and other products with a wall thickness of less than 2mm into granules. It is suitable for the agglomeration of waste products or films made of soft PVC, HDPE, LDPE, PP and other thermoplastics.

The pellets can be used directly in an extruder or injection molding machine. It can also be further granulated according to some advanced requirements.

Specification

application:

Applicable plastic materials: PE, HDPE, LDPE, PP, BOPP, etc.

Material shape: film, bag, (PE, PP) recycled material

Material Type: Roll, Bulk, Bundle

Materials are sourced from scrap, industrial defect films, water wash films and printed films.

NOTE: Depending on the material properties, different downstream equipment is required.

Applicable plastic materials: PE, HDPE, LDPE, PP, BOPP, etc.

Material shape: film, bag, (PE, PP) recycled material

Material Type: Roll, Bulk, Bundle

Materials are sourced from scrap, industrial defect films, water wash films and printed films.

NOTE: Depending on the material properties, different downstream equipment is required.

Model | Volume (L) | Effective Volume (L) | Spindle Speed (rpm) | capacity (kg/hour) | heating method | freed method |

ZL-100 | 100 | 75 | 800 | 80-100 | on their own friction | manually or pneumatic |

ZL-200 | 200 | 150 | 800 | 150-200 | ||

ZL-300 | 300 | 225 | 800 | 250-300 | ||

ZL-500 | 500 | 375 | 750 | 450-500 | ||

ZL-800 | 800 | 600 | 750 | 750-800 |

Contact us to learn more...

Why choose us

Suzhou Bikland Machinery

Dedicated to R&D and manufacturing of cleaning equipment for ten years, and exported to more than 20 countries in Europe, America, Asia, Africa, etc., with a team of 5 engineers, 7 foreign trade personnel, and 38 employees, undertaking various high-end customized machines, with a small sales economy The capacity cleaning line is deeply loved by new and old customers. Dedicated to the research and development and manufacturing of cleaning equipment for ten years, and exported to more than 20 countries in Europe, America, Asia, Africa, etc., with a team of 5 engineers, 7 foreign trade personnel, and 38 employees, undertaking all kinds of high-end customized machines, economical sales The small batch cleaning line is deeply loved by new and old customers.

VIEW MORE

You may like

-

Unvulcanized Steel Cord Scrap Rubber Steel Wire Separator

-

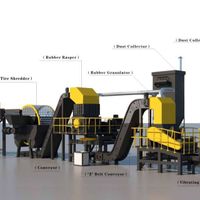

Tire recycling plant for waste recycling equipment

-

Semi-automatic waste tire recycling into rubber powder machine tire cutting machine

-

High-performance used tire recycled rubber production line rubber powder making machine tire recycling production line

-

Reclaimed rubber production equipment

-

Used tire cutting machinery, tire recycling machinery for sale

-

Factory sale 1-2 tons waste tire rubber shredder recycling plant

-

Waste tire wire separator/tire wire remover/tire wire remover

-

Zero consumption tire doubling machine used tire doubling machine for sale

-

waste tire recycling machine used tire recycling shredder factory in pakistan