Copper wire crusher copper wire separator Copper wire granulator

-

Supplier: Baoding Baonan Machinery And Equipment Manufacturing Co., Ltd. -

Region: Hebei, China -

Contact: Mr Peter Wu -

Price: $6400.00 / 1 - 9 sets

$5600.00 / >=10 sets -

Min. Order: 1 set

| Payment Terms: | L/C,T/T; | Key Selling Points: | Smashing small particles, high sorting purity; |

| Applicable Industries: | Other; | Wire processing range: | 0.02-50mm; |

| Warranty: | 1year,1 Year; | Power (kW): | 10; |

| Machinery Test Report: | Provided; | Core Components: | Engine,Gearbox,Motor,Gear,Pump; |

| Keyword: | Copper wire crusher copper wire separator Copper wire granulator; | Condition: | New; |

| Material / Metal Processed: | Brass / Copper,Carbon steel,Aluminum; | Weight (KG): | 1450; |

| Showroom Location: | None; | Input: | 40-60KG/H; |

| Place of Origin: | Hebei, China; | Warranty of core components: | 1 Year; |

| Port: | xingang port; | Recovery rate: | 99%; |

| Packaging Detail: | 1. Standared export package, carton box, Film Package/steel frames Package/customer requirement 2. 20 feet container, 40 feet container; | Blade material: | SKD11(D2); |

| Marketing Type: | New Product 2021; | Certification: | CE; |

| Weight of machinery: | 1100Kg; | Product name: | Waste cable granulator; |

| Package Preview: | ; | Size: | 1600*1600*2000; |

| Supply Ability: | 100 Sets per Month; | Video outgoing-inspection: | Provided; |

Baoding Baonan Machinery And Equipment Manufacturing Co. Ltd, orienting at research, development, manufacture and sales, is a professional and productive entity enterprise, specialized in manufacturing solid waste and garbage recovery processing equipment. It locates in Bizhuang industrial park, covering a total area of thirty thousand square meters. Our company mainly produce copper wire granulator, scrap metal shredding equipment, waste metal separating and sorting equipment, eddy current separator, cleaning and drying equipment. In addition, our company can provide project design, process design, machinery purchasing selection, as well as design and manufacture products according to the special needs of customers, also conduct technical training.

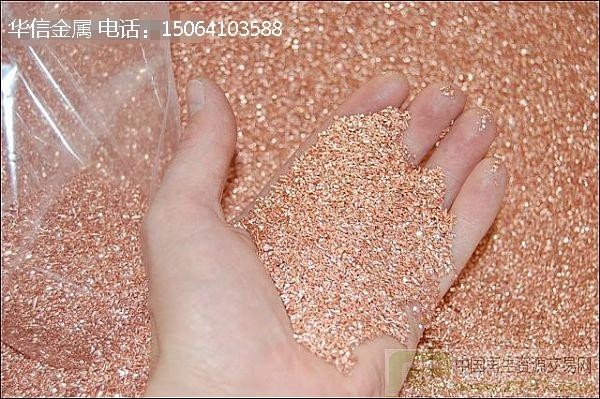

Copper wire crusher copper wire separator Copper wire granulator

This kind of machine is mainly used to recycle all kinds of waste cable wires, the raw materials will be separated into copper and PVC, the applicable range of the wires diameter from 0.02 mm to 50 mm, such as automobile electrical wires, car bottom wires, motorcycle electric wires, computer copper wires and communication cable, etc.

Copper wire crusher copper wire separator Copper wire granulator | ||||||||

Type | Engine modelMeas.(m) | Weight(t) | Power(kw) | Input(kg/h) | ||||

TM-300A | 1.6*1.6*2.0 | 1.5 | 8.69 | 40-60 | ||||

TM-300 | 3.5*2.0*4.0 | 4.5 | 17 | 150-200 | ||||

TM-400 | 4.5*1.6*4.0 | 4.8 | 65 | 400 | ||||

TM-600 | 5.0*1.8*4.1 | 6.5 | 76.45 | 600 | ||||

TM-800 | 5.5*1.8*4.1 | 8.8 | 80.75 | 800 | ||||

Main Features

2. Integrated structure, easy to install and debug, convenient to transport, stable performance.

3. Blade and screen use special wear resistance and high toughness alloy material to reduce the production cost.

4. Double roller, low speed to guarantee the feeding efficiency

5. No dust, no secondary pollution

6. Copper purity 99.9%

7. Pulse dust collector

1- How to choose proper products you want?

• Please tell us as detail as what you want?

• What's your raw material ?

• What's the final products you want to produce?

• What capacity you want it performance?

2- How to control the quality?

• We have technical, engineer team design the sample machinery before enter into market

• Production QC team ensure the machine manufacturing quality

• We will running every machine after finished before shipment

• Optional choose by client running the machinery by material

20GP container or 40GP container

Loading container at factory.

2.Delivery

** We can shipping the goods by air or by sea.

** We will send pictures of cargo loading to our client to check and keep recording.

** We can send cargo to client's warehouse to loading

**.We have free spare parts with the machine.

• Pre-sale: we given client the details technician offer, sign the sales contract etc.

• In-sales: we supply the details layout, installation instruction, technician support for the clients.

• We have free spare parts with the machine.

• We supply long term spare parts for every customer.

• We always up date the new technology to every customer.

-

V-S30 Fully Automatic Scrap Copper Wire Granulator Recycling Machine Copper Recycling Machine

-

High performance small copper cable shredder mini cable shredder used copper wire shredder

-

High-quality PCB recycling equipment/PCB dismantling machine

-

BSGH Mini Cable Granulator Waste Cable Wire Separator Recycling Machine at 220 V with the most advanced technology and good quality

-

industrial iron ore crusher plant price

-

Shredder Double Shaft Shredder, Shredder, Waste Plastic Shredder

-

2022 Best Selling Cable Wire Granulator Grid Grinding Separator Recycling Machine

-

Factory direct sales metal pipe bender round pipe bender iron pipe bender

-

Double shaft scrap metal shredder used car shredding scrap metal shredder

-

Copper Wire Pelletizer Splitter/Small Copper Wire Pelletizer