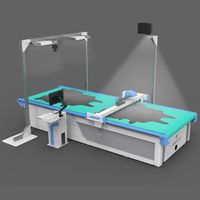

Kamege K420L Band Knife Leather Splitting Machine

-

Supplier: Dongguan Xiangdi Machinery Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Coral Liu -

Price: $14500.00 / 1 - 1 sets

$14000.00 / 2 - 4 sets

$13800.00 / 5 - 9 sets

$13200.00 / >=10 sets -

Min. Order: 1 set

Product details

| Certification: | CE, Rohs; | Place of Origin: | Guangdong, China; |

| Showroom Location: | Turkey,United Kingdom,United States,Italy,Viet Nam,Philippines,Pakistan,India,Spain,Thailand,South Korea,Bangladesh,South Africa,Japan,Poland; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; |

| Minimum thickness: | 0.05mm; | Port: | Shenzhen,Guangzhou; |

| Maximum thickness: | 8mm; | Type: | SPLITTING MACHINE; |

| Condition: | New; | Power: | 2.7KW,2.7kw; |

| Core Components: | PLC,Bearing,Motor,Gear; | Voltage: | 380/220V; |

| Marketing Type: | Hot Product 2021; | Applicable Industries: | Leather goods,Shoes,Garment; |

| Supply Ability: | 20 Sets per Month; | Net weight: | 630kg; |

| Packaging Detail: | Wooden case with plastic film,pallet; | Automatic Grade: | Automatic; |

| Machinery Test Report: | Provided; | Warranty of core components: | 1 Year; |

| Video outgoing-inspection: | Provided; | Brand Name: | Kamege; |

| Knife size: | 3500*50*0.7mm; | Package Preview: | ; |

| Warranty: | 1 Year; | After Warranty Service: | Video technical support; |

| Dimension: | 1700*1300*1100mm; | Weight: | 630 KG; |

| Working width: | 420mm; | Dimension(L*W*H): | 1760*1230*1440mm; |

Products Description

Purpose

It is suitable for all kinds of high-precision layered operation of genuine leather, leather, PVC, EVA, ultra filament, rubber and other materials in belt, cell phone cover, handbag, luggage, shoemaking, electronic products, stationery, sporting goods, auto tyre, pipeline detection and other industries, with a minimum thickness of 0.1mm!

Features

1.Feeding speed is controlled by touch screen;

2.It is equipped with the function of calculating and displaying production schedule target and output, and users can master the status of processing quantity in real time;

3.It is equipped with video function, and the display contents include operation video file, fault video file and maintenance

video file;

4.The 1.5KW power cutter wheel motor is adopted to solve the processing problem of hard and soft leather in large sheet;

5.The strong wind blade is used in motor, which makes the dust suction more powerful;

6.It is equipped with backwards function;

7.The internal structure of the machine is formed by integrally casting;

8.Electrical box: it is controlled by PLC system with higher stability; imported circuit components are used to improve control and service life; EU-US 24V DC safety operation voltage; unique phase sequence protection device and filter device; thermal protection of all motors; it is compatible with three-phase 380V and three-phase 220V; customized single-phase 220V; CE certified;

9.It is equipped with device of automatic dust removal, sharpening and clutch unit, optical microscope, etc., to keep machine clean with good working environment;

10.Centrifugal vacuum cleaner is used in the dust collection system.

It is suitable for all kinds of high-precision layered operation of genuine leather, leather, PVC, EVA, ultra filament, rubber and other materials in belt, cell phone cover, handbag, luggage, shoemaking, electronic products, stationery, sporting goods, auto tyre, pipeline detection and other industries, with a minimum thickness of 0.1mm!

Features

1.Feeding speed is controlled by touch screen;

2.It is equipped with the function of calculating and displaying production schedule target and output, and users can master the status of processing quantity in real time;

3.It is equipped with video function, and the display contents include operation video file, fault video file and maintenance

video file;

4.The 1.5KW power cutter wheel motor is adopted to solve the processing problem of hard and soft leather in large sheet;

5.The strong wind blade is used in motor, which makes the dust suction more powerful;

6.It is equipped with backwards function;

7.The internal structure of the machine is formed by integrally casting;

8.Electrical box: it is controlled by PLC system with higher stability; imported circuit components are used to improve control and service life; EU-US 24V DC safety operation voltage; unique phase sequence protection device and filter device; thermal protection of all motors; it is compatible with three-phase 380V and three-phase 220V; customized single-phase 220V; CE certified;

9.It is equipped with device of automatic dust removal, sharpening and clutch unit, optical microscope, etc., to keep machine clean with good working environment;

10.Centrifugal vacuum cleaner is used in the dust collection system.

Model | K420L |

Working width | 420mm |

Maximum thickness | 8mm |

Minimum thickness | 0.05 |

Knife size | 3500*50*0.7mm |

Power | 2.7KW |

Dimensions/Packing dimensions | 1600*1100*1220mm/1700*1170*1440 |

N.G/G.W. | 630kg/730kg |

Manufacturing technique

Product effect

Testing the hard leather to 2mm

Testing the soft leather to 0.2mm

Testing the rubber to 2mm

Company Information

Packaging & Shipping

Our Service

Exhibition

Manufacturing strength

Certifications

Related Products

VIEW MORE

You may like

-

Electric dual motor cutting machine press leather die cutting punching machine

-

ZXT fully automatic digital industrial CNC genuine clothing natural leather cutting machine for sale

-

Leather strip cutting machine and tape folding machine

-

60 tons single side automatic feeding hydraulic round bubble cleaning/leather/sponge scrubbing/pad/die cutting machine

-

Jindex Sofa Upholstery Shoes Automatic Leather Cutting Machine, PU Pattern Automatic Knife Cutting Machine China Supplier Hot Sale

-

Horizontal belt edge dyeing machine leather men and women leather oil edge machine

-

Leather processing drum for full line leather production

-

Leather ironing machine Leather warm roll electroplating embossing machine Belt belt making machine

-

Precision hydraulic leather belt embossing machine

-

VS925L Shoe Machine Atomic Refurbishment 25 Tons Swing Arm Cutting Press

Other Products

-

$2164.00 - $2348.00 / set

$2164.00 - $2348.00 / set -

$1500.00 / set

$1500.00 / set -

$65.00 / set

$65.00 / set -

$79.00 - $90.00 / set

$79.00 - $90.00 / set -

$1428.00 - $1587.00 / set

$1428.00 - $1587.00 / set -

$320.00 - $500.00 / set

$320.00 - $500.00 / set -

$57.00 / piece

$57.00 / piece -

$181.00 / set

$181.00 / set -

$500.00 / set

$500.00 / set