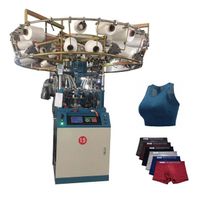

Legging knitting machine, Pantyhose knitting machine, Tights knitting machine

-

Supplier: SANTAMORA ENTERPRISE CO., LTD. -

Region: Fujian, China -

Contact: Mr KINGKNIT ENTERPRISE -

Price: $3000.00 /set -

Min. Order: 1 set

Product details

| Applicable Industries: | Manufacturing Plant; | Product Name: | Legging knitting machine, Tights knitting machine; |

| Supply Ability: | 300 Set/Sets per Month; | Port: | any port in china; |

| Product Type: | Underwear; | Knitting Method: | Double; |

| Place of Origin: | Taiwan; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| Production Capacity: | High; | Knitting Style: | Warp; |

| Dimension(L*W*H): | 2650*850*160mm; | Packaging Detail: | Export standard searworthy wooden case.If export to european countries,the wooden box will be fumigated. If container is too tigher,we will use pe film for packing or pack it according to customers special request.; |

| Brand Name: | KING KNIT; | Warranty: | 1 Year; |

| Weight: | 380kg; | Condition: | New; |

| Power(W): | 1.5KW; | Name: | pantyhose knitting machine; |

| Type: | circular; | Computerized: | Yes; |

| Type: | Circular; | Keywords: | Legging Knitting Machine; |

| After-sales Service Provided: | Video technical support,Online support,Free spare parts,Field maintenance and repair service; | Knitting Style: | weft knitting; |

| Knitting Method: | Double; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

Product Description

Legging Knitting Machine ,Pantyhose Knitting Machine , Tights Knitting Machine

Product Functions and Advantages

1 .Since the high speed legging seamless knitting machines is provided with small tailor-made needles,its yarn feeders are three more than those of a common high speed mini circular knitting machine, which effectively improve production efficiency.

2. The powerful computer control system is applied to automatically monitor and control every running parameters,including spraying oil in fixed quantity and al regular lime, dust removing, needle breakage detection, auto-stop if the fabric is broken or the rated volume of production is reached, etc.

3. In order to successfully avoid deformation caused by environmental factors and increase knitting system precision,its frame is mainly made of gray iron allay and has received natural aging treatment. The oil-immersed gear meshing drive model is adapted awing to its high stability and less noise.

4.Designed with 2tracks for dial and 4tracks for cylinders, Through replacement of needles and cams , it can produce a variety of knitting fabric.

Detailed Image

Application of underwear knitting machine

Can make all kinds of apparel such as underwear, outerwear, swimwear, sportswear,medical wear etc, which with terry or tuck stitch. The yarn can be natural fiber, synthetic fiber and artificial fiber etc. Machine can knit terry in any part of fabric to make fabric with good warmth retention and moisture absorption, also make fabric more softness. Machine can also knit tuck stitch in any part of fabric, which make fabric with more pattern designs

Our Company

VIEW MORE

You may like

-

Plain cord fabric two-end electric placket knitting machine

-

Semi-automatic manual flat knitting machine for home use knitting machine China

-

KH brothers semi-automatic manual manual full jacquard computer sweater leader flat knitting machine

-

KH Brother Manual semi-automatic sweater hat scarf collar flat knitting machine

-

Seamless underwear machine

-

Knitting Machine Low Price 48 Needles Circular Knitting Crochet Knitting Machine For Socks Hat Scarf Sweater Diy

-

Smart Weaver Knitting Kit Machine Oversized 48 Hand Crank DIY Wool Knitting Machine Hat Knitting Machine Toy Girl House Kids

-

48 Needles Sock Knitting Machine Small Sentro 48 Needles Circular Plastic Educational Toys Home Sweater Knitting Machine

-

Hollow round flat shoelace rope crochet machine knitting knitting machine

-

Second hand flower shima seiki new ses 122s 12g flat knitting machine

Other Products

-

$2300.00 / set

$2300.00 / set -

$1500.00 / set

$1500.00 / set