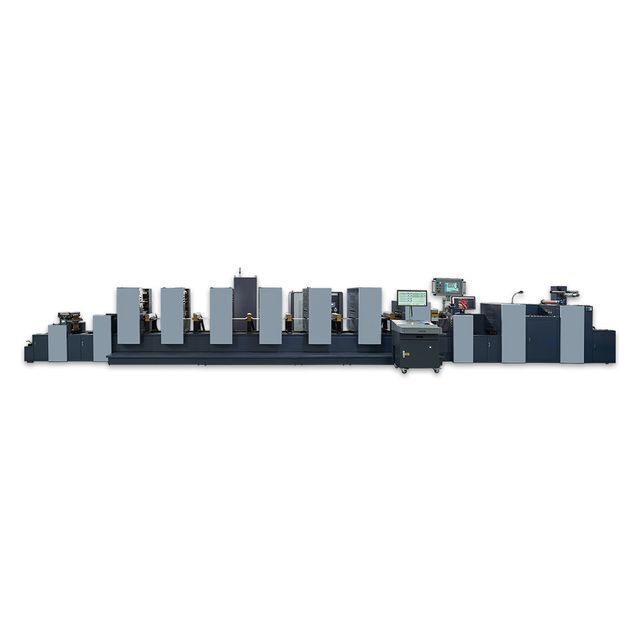

DABA Automatic digital label offset printing machine for blank paper cup

-

Supplier: Wenzhou Daba Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Alex Xu -

Price: $230000.00 /set -

Min. Order: 1 set

Product details

| Usage: | Card Printer,Label Printer,Paper Printer,Bill Printer,Tube Printer,Cloths Printer; | Applicable Industries: | Manufacturing Plant,Food & Beverage Factory,Retail,Printing Shops,Construction works ,Energy & Mining,Other,Advertising Company; |

| Printing Speed: | 2000-7000 Sheets/hour; | Function: | Paper Printing; |

| Max Printing Size: | 605 * 440mm; | Brand Name: | DABA; |

| Package Preview: | ; | Dimensions(L*W*H): | 9850*1800*1950; |

| Packaging Detail: | By seaworthy wooden case; | Type: | Offset Printer; |

| Video outgoing-inspection: | Provided; | Max. Paper Size: | 560mm; |

| Weight: | 10000 KG; | Certification: | CE; |

| Color & Page: | Multicolor; | Machinery Test Report: | Provided; |

| Marketing Type: | New Product 2020; | Automatic Grade: | Automatic; |

| Showroom Location: | None; | Port: | Ningbo/Shanghai; |

| Voltage: | 3Phase 380v; | Core Components: | Bearing,Motor,Pump,Gear,PLC,Other,Gearbox,Pressure vessel,Engine; |

| Supply Ability: | 5 Sets per Month; | Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram; |

| Plate Type: | offset printer; | Color Unit Number: | Multi Colour; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Place of Origin: | Zhejiang, China; |

| Warranty: | 1 Year; | Condition: | New; |

| Key Selling Points: | Automatic; | Warranty of core components: | 1 Year; |

| Application: | Offser Printing Machine; |

Product Description

Main Features

Intermittent Label Offset Printing Machine adopts latest servo control system which can ensure the material nip steady and accuracy. It can free from the printing roller change.

The operation of this machine is faster, convenient and simple. PS plate intermittent printing hits the high level label demands from short run to long run. It’s the best choice for printing highest quality labels with lowest production cost.

The operation of this machine is faster, convenient and simple. PS plate intermittent printing hits the high level label demands from short run to long run. It’s the best choice for printing highest quality labels with lowest production cost.

Machine Parameter | ||||

Model | DBJY-320 | DBJY-450 | ||

Printing speed | 50-180 rpm/min | 50-150 rpm/min | ||

Printing color | 4-10colors | 4-10colors | ||

Max. printing length | 350mm | 380mm | ||

Max. web width | 320mm | 470mm | ||

Max. printing width | 300mm | 450mm | ||

Max. unwinding diameter | 700mm | 700mm | ||

Max. rewinding diameter | 600mm | 600mm | ||

Power supply | 3 phase 380V | 3 phase 380V | ||

Total power | 33.6kw(without UV power) | 40kw(without UV power) | ||

Dimensions(L×W×H) | 10550×1600×1800mm | 11150×1700×1800mm | ||

Main machine weight | about 9.5t | about 11.5t | ||

Details Images

1.Unwinding Unit

2.Web Guide

control paper move straightly

3.Heavy Offset Printing Unit

Printing unit: adopting high quality and heavy offset printing unit.

Assembled with 19 pieces of ink rollers,4pcs of Form Rollers and 4pieces of Water rollers (alchohol dampening system), has nice inking system which can largely avoid gear mark and ghost image.

The fine and accurate printing would never be reached by flexo/letterpress machine.

4.Shaftless Driving System

Every printing unit run by an independent servo motor, 15 sets of servo motors in total for whole machine (6color) to ensure the exact color registration during high speed operation. The vertical and horizontal motions of every printing unit are all controlled by independent motor (ease the laboring and reduce the waste).

5.Video Inspecting System

By video still system, the machine can regulate vertical & horizontal registering without stopping, it improves the printing quality and increases the producing capacity.6.Touch Screen Control System

Touch LCD screen, faster CPU, 12inch operating display, independent touch screen in each printing unit, powerful human-computer dialogue system, multi-guide inspecting display interface, instant alarm signal, makes operation much easier and more efficient.7.Printing Unit Control Pannel

8.Computer Ink Control System

9.Traction Unit

10.Quality Checking Unit

11.Lamination Unit

12.Rewinding Unit

1.Second Pass Register Sensor

Super large printing area of 300x350mm, the max repeat length can go up to 350mm and the max running speed can be 63m/min.By high-precision photocells, the machine ensures multi-register print on both side, make the possibility of label variety.

2.Cold Foiling Unit

Inline cold foiling, has the characteristic of fast speed, high efficiency, increase the decorative effect for color and graphic.

3.Rotary die cutting station

One big magnetic cylinder used in this machine, largely saves the tooling cost. Different die-cutting job can be achieved by

changing the flexible die.

changing the flexible die.

4.Flexo UV Varnishing Unit with Chamber System

Flexo UV varnishing unit (both solid and spot) makes the printing more shining and attractive.

5.Delam/Relam Unit

Delaminate the adhesive label , then printing on glue surface and re-laminating.6.Screen Printing Unit

Inline flat screen printing, has characteristic of thick ink layer, strong relief perception.

Applicable Material:

* Self-adhesive paper,Self-adhesive thermal paper,thermal paper ATM etc.

* Self-adhesive film:Self-adhesive PE film,Self-adhesive PET film,Self-adhesive PVC film,etc.

* plastic film:Cpp film,PET film,PVC film,PE film,etc.

* Laminating Film.

* Paper material:kraft paper,paper cup paper,etc.

* Self-adhesive film:Self-adhesive PE film,Self-adhesive PET film,Self-adhesive PVC film,etc.

* plastic film:Cpp film,PET film,PVC film,PE film,etc.

* Laminating Film.

* Paper material:kraft paper,paper cup paper,etc.

Application Industry:

* Food product label, Anti-counterfeit label, Daily chemical products label, Medicines label, Chemical label, Paper cup paper,Blank label,etc.

Samples show

In Factory Photo

Our Service

1.Purchase Service

DABA COMPANY have a specialize and efficiency working team.If you are new onthe printing and packing area Some samples of your

products could be shew to uswill be appreicate we will give you specialized suggestion of whole work

DABA COMPANY have a specialize and efficiency working team.If you are new onthe printing and packing area Some samples of your

products could be shew to uswill be appreicate we will give you specialized suggestion of whole work

2.Shipping Service

DABA COMPANY have a spcialized and independent department which just for

shipping the buyer's goods.The workers are knowing T/T,L/C Items well.All Exporteddocuments could be made perfectly

DABA COMPNAY cooperate with the most famous shipping company in China also.

They could provide the best and economic shipping ways to the buyer's port.

DABA COMPANY have a spcialized and independent department which just for

shipping the buyer's goods.The workers are knowing T/T,L/C Items well.All Exporteddocuments could be made perfectly

DABA COMPNAY cooperate with the most famous shipping company in China also.

They could provide the best and economic shipping ways to the buyer's port.

3.Installation Services

Installation Services are available with all DABA Company machines.DABA Comapnywill dispatch technician to The Buyer's factory to

installation and preoperation ofmachines But the buyer need to surpply the round trip tickets food hotel cost.

Installation Services are available with all DABA Company machines.DABA Comapnywill dispatch technician to The Buyer's factory to

installation and preoperation ofmachines But the buyer need to surpply the round trip tickets food hotel cost.

4.Clients Training Services

DABA Company advise The buyer could send own technican come to DABA factoryto learn how to operate machines.DABA Company

technician will teach and train thelerners hand by hand till he can operate machine by himself.

Obviouslly,Traning within Installation period is acceptable.

DABA Company advise The buyer could send own technican come to DABA factoryto learn how to operate machines.DABA Company

technician will teach and train thelerners hand by hand till he can operate machine by himself.

Obviouslly,Traning within Installation period is acceptable.

5.After Sales Service

DABA Company machines guarantee time is one year.

Many easy broken spare parts will be prepared in the tool box together with

machines.Any parts broken Just a pictures or a videos.The new free parts will reachwithin 3-7 Express working days.

DABA Company machines guarantee time is one year.

Many easy broken spare parts will be prepared in the tool box together with

machines.Any parts broken Just a pictures or a videos.The new free parts will reachwithin 3-7 Express working days.

Company Information

Packing & Delivery

FAQ

Q: What's your delivery date? A: Usually finish the production within 30days after your 30% advanced payment, actually need to check according our stock & production plan.

Q: Terms of payment?

A: We accept T/T, 30% in advance and 70% balanced against B/L copy. We accept L/C at sight. We accept Cash.

Q: How many days will you finish installing ?

Q: How many days will you finish installing ?

A: We will finish installation and training within 15days.

Q: How long is your machine's warranty period?

A: All our machine have one year guarantee, starting from finished installation.

Q: How could we do after one year warranty period?

A: We also can do service for you, however, if require overseas service, you need pay salary to our technician 100USD/day.

Q: How could we do if the parts broken within warranty?

A: We would express the free replacement parts during the warranty date.

Q: How many worker do we need running those machines?

A: For flexo printing, slitting, die-cutting machine, only need one person for each.

Q: What should we charge for your engineer?

A: You should charge for the cost of our engineer's visa , air tickets, hotel, food ,and also their salary 100USD one day per person.

VIEW MORE

You may like

-

Second-hand offset printing machine Heidelberg GTO 52 one, two and four colors ready for shipment

-

Second-hand offset printing machine two-color GTO52 2-color offset printing machine made in Germany

-

Used Heidelberg Kord 64 Kord 72 offset printing presses

-

Magazine multi-color printing 4-color offset printing machine price

-

Quality Reliable German Made Used Automatic Offset Presses For Sale

-

Top Dealer for Low Maintenance Used Automatic Offset Presses

-

paper die cutter pol ar orignal germany using massikot 92cm 115cm

-

Four-color second-hand German Heidelberg offset press SM74 SM52 MoV MOZ

-

German CMYK 4-color offset press

-

Similar Speedmaster Heidelberg offset presses for magazines

Related Search

mini offset printing machine for paper

offset printing machine for paper

offset printing machine for cans

automatic offset printing machine ce

3d digital printing machines for sale

offset printing machine

transfer printing machines for t-shirt

a2 paper four 4 color offset printing machine

max offset printing machine

one color mini offset printing machine