Pinch Valves Rubber Sleeve

-

Supplier: Flowmiles -

Region: Anhui, China -

Contact: Ms Zhu Alice -

Price: -

Min. Order: 1 set

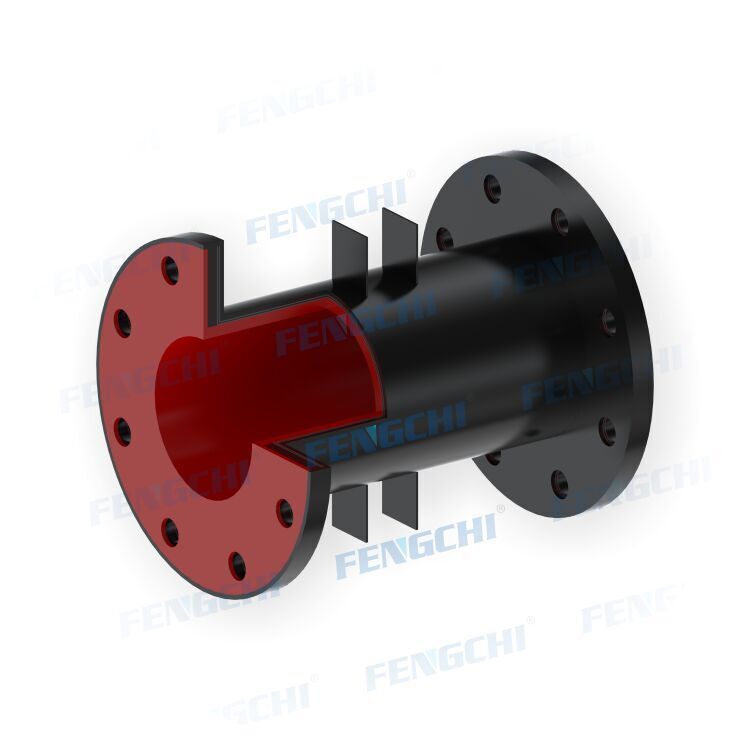

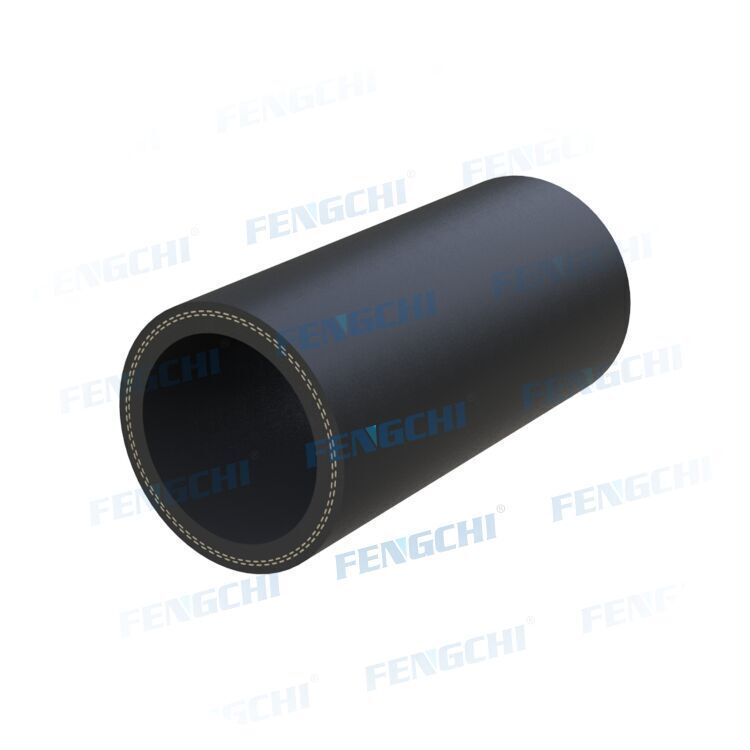

Rubber sleeve is the most important component for any type of pinch valves, it is the core of pinch valve.

Rubber sleeve provides corrosion & wear resistance, and pressure bearing capacity. The quality of pinch valve is as good as the quality of its sleeve.

Technical specifications

Size range: 15~2000mm ,1/2~80in

Pressure grade: 1~10Mpa

1:2 safety factor, which means bursting pressure is 2 times higher than the operating pressure.

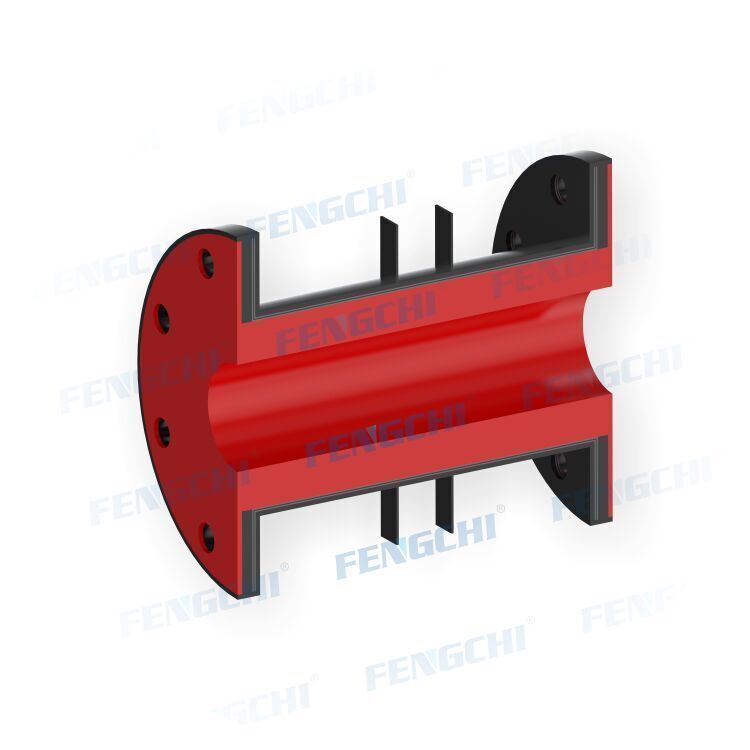

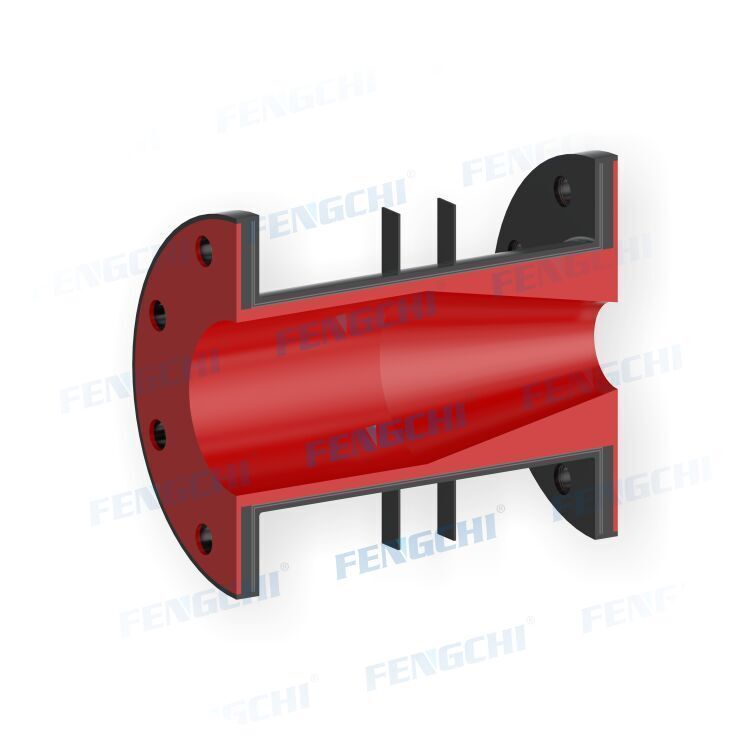

Analysis of construction

Inner Layer: adopt various kinds of rubber materials or formulas in order to fit for the high demanding applications involving abrasion, corrosion or high temperature, etc.

Reinforced layer: the perfect combination of synthetic rubber and synthetic fibre technology forms a unique reinforced skeleton, which enables the sleeve to bear pressure and fatigue.

Outer layer: Using Natural Rubber to protect and reinforce the flexure resistance of valve sleeve.

Opening tags: the middle part of the outer layer is equipped with opening tags to solve the problem of fixation and tensile strength of the inner sleeve and actuator, also to ensure full opening of valves in all process conditions.

Handmade

Each FENGCHI® pinch valve sleeve is handcrafted by professionally trained personnel, each sleeve is affixed with labels, which contains relevant parameters and numbers in order to provide a basis for quality traceability.

Material, features and matching process conditions

|

SBRT |

Severe wear high-frequency operation |

-40~+110℃ |

Abrasive material, weak acid, weak base and other chemical media |

|

EPDM |

Chemical applications Applicable to 75% of all industrial chemical applications |

-40~+120℃ |

Concentrated and oxidizing chemicals |

|

NR |

Strong abrasive and corrosive conditions |

-40~+75℃ |

Abrasive materials. Weak acid, weak base and other chemical media |

|

NRF |

foodstuff applications Compliant with FDA (Food & Drug Administration ) requirements. |

-40~+75℃ |

Media used in food and other alcohol used in CIP (clean-in-place) processes. |

|

NRL |

Strong abrasive and corrosive conditions (including slurries ) |

-40~+75℃ |

Abrasive pulp such as ore pulp. Weak acid, weak base and other chemical media

|

|

NBR |

suitable for oil and aliphatic hydrocarbons |

-30~+100℃ |

Oil, fat, fuels, Hydrocarbons, Lubricants, etc. |

|

NBRF |

Applications of fatty foodstuff, compliant with FDA (Food & Drug Administration ) requirements |

-30~+100℃ |

Vegetable and animal oils and fats |

|

HNBR |

high temperature applications |

-30~+160℃ |

Oils, fats, fuels, Hydrocarbons, Lubricants, etc. |

|

CR |

Applications of special-purpose chemicals. Resilient to Ozone and bad weather. |

-30~+100℃ |

Chemicals, acids, several solvents, fatty oils, greases, lubricants. |

|

FPM |

Applications of special-purpose chemicals. Resilient to Ozone and bad weather. |

-20~+120℃ |

Chemicals, fatty oils, aromatic and halogenated hydrocarbon. |

|

CSM |

Applications of special-purpose chemicals. Resilient to Ozone and bad weather. |

-40~+100℃ |

Chemicals, acids, several solvents, fatty oils, greases, lubricants. |

|

IIR |

Applications of special-purpose chemicals. Impermeable to gas. |

-40~+100℃ |

Concentrates and Acidic Chemicals. Vegetable oils.

|

|

PU |

Process conditions of abrasive mediums. |

-10~80℃ |

Abrasive materials, dilute chemicals, hydrocarbon oils, lubricating oils. |

-

IEVLEAD AD1-EU7

-

DIN Basket Strainer: DIN EN 12516-1, BS EN 12516.1, EN 12516

-

DIN EN 12516-1 Y Strainer, DN15-DN600, PN6-PN100, RF

-

API 600 Bolted Bonnet Gate Valve, 2-16 Inch, Class 150-2500 LB

-

Rail gap ruler Rail feeler

-

Portable electric rail drilling machine

-

Portable digital switch rail lateral wear gauge for quick and easy inspections

-

Lithium battery powered railway track inspection vehicle

-

Internal combustion engine railway Ballast Tamper

-

Hand track jack mechanical railroad lifting machine