50l 100l 200l 250l 300l 400l 500l 600l 800l 1000l stainless steel jacketed conical beer fermenter tank

-

Supplier: Shandong Yuesheng Beer Equipment Co., Ltd. -

Region: Shandong, China -

Contact: Ms Suri Lee -

Price: $850.00 /piece -

Min. Order: 1 piece

| Packaging Detail: | Export standard, maximum protection, including: Wooden case, angle steel, plastic film, bubble film.; | Power: | customized; |

| Dimension(L*W*H): | customized; | Warranty of core components: | 3 years; |

| Package Preview: | ; | Voltage: | 220V/380V/415V/customized; |

| Showroom Location: | United States,Italy,France,Brazil,Chile; | Marketing Type: | New Product 2020; |

| Port: | QINGDAO; | Washing way: | CIP spray ball; |

| Warranty: | 3 years for main equipments; | Fermenter cone: | 60 degree; |

| Applicable Industries: | Hotels,Manufacturing Plant,Food & Beverage Factory,Restaurant,Food & Beverage Shops; | Cladding thickness: | 2mm; |

| Machinery Test Report: | Not Available; | Key Selling Points: | High Safety Level; |

| Brand Name: | YUESHENG; | Supply Ability: | 30 Pieces per Month fermentation tank; |

| Weight: | KG; | Inside polishing: | 0.4 micrometer; |

| Core Components: | Pressure vessel; | Insulation thickness: | 80mm; |

| Plate surface: | mirror,wire drawing,2B; | Cooling way: | with glycol cooling jacket; |

| Machinery Capacity: | 50l-20000l; | Inner tank thickness: | 3mm; |

| Insulation layer: | polyurethane; | Payment Terms: | L/C,T/T; |

| Condition: | New; | Material: | stainless steel 304/316; |

| Processing: | Fermenting Equipment; | Video outgoing-inspection: | Provided; |

| Processing Types: | Alcohol; | Place of Origin: | Shandong, China; |

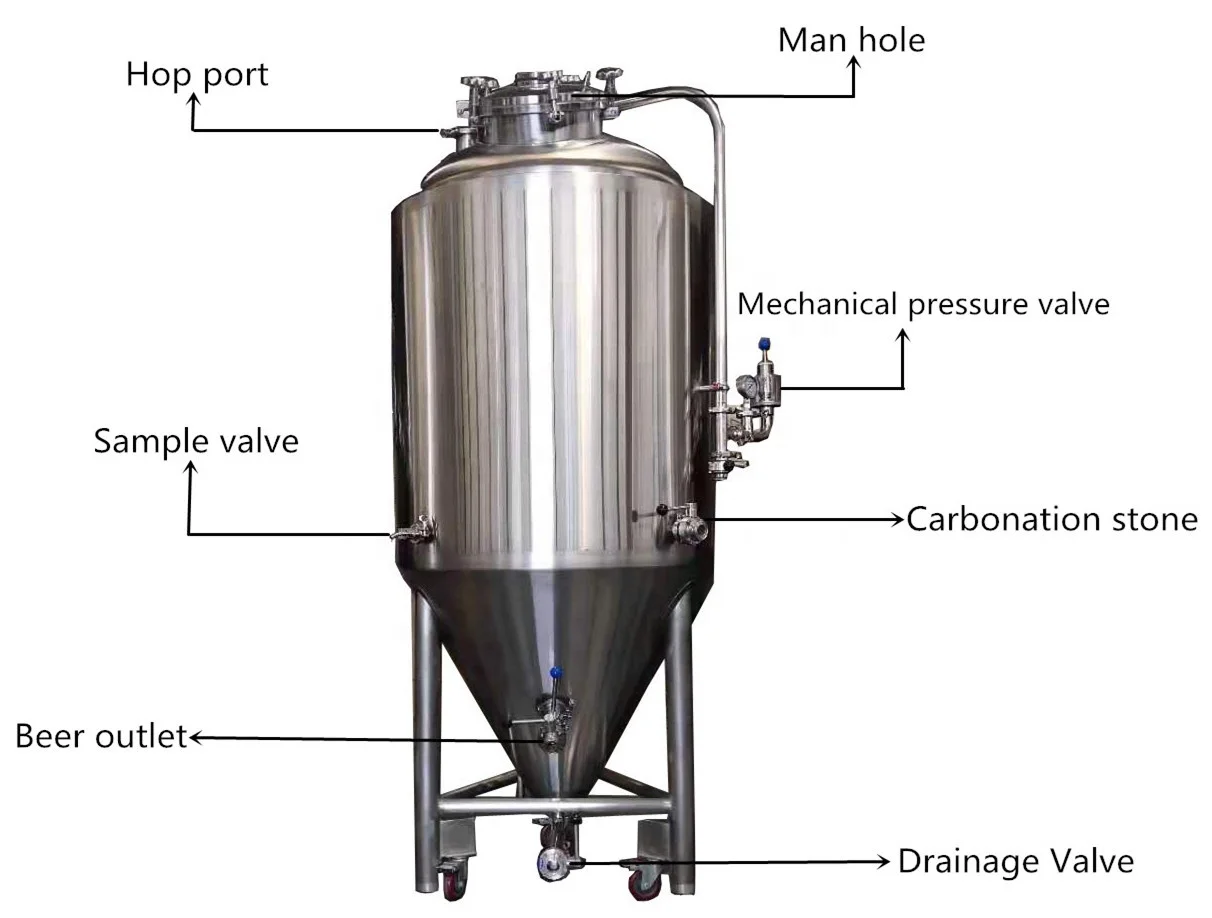

50l 100l 200l 250l 300l 400l 500l 600l 800l stainless steel jacketed conical beer fermenter tank

Fermenter tank configuration:

| Function | Beer Fermentation |

| Total capacity | Effective capacity +25% Headspace minimum |

| Interior Shell | SUS304 full welded; TH=3mm |

| Exterior Shell | SUS304 full welded; TH=2mm |

| Insulation | polyurethane,, TH=80/100mm |

| Glycol Jacket | Dimpled plate on cone and side,TH=1.5mm |

| surface treatment | Surface brushed; Polish treatment |

|

Control way |

Individually temperature controlled by PLC or DCS |

| Washing way | CIP spray ball, in the center of the inside tank |

| Bottom cone | 60-90 degree |

| Manway | top manhole or side manhole |

| Temperature control ways |

Platinum resistance thermometer and Direct reading thermometer, display temperature from intelligent data meter |

| Temperature measurement system | Temperature sensor PT100, temperature display by intelligent data meter |

| Pressure control system | Automatic control electric connected pressure gauge |

| Tank pressure | Design pressure 0.3MPa; Working pressure 0.2Mpa |

| Valves and fitting | Matched valves SUS304 1)Solenoid water valve; 2)Solenoid relief valve 3)Butterfly valves;(Bottom outlet Butterfly valve:DN40) (Racking Butterfly valve: DN32) 4)Sample valves; 5)Beer outlet valves; 6)Drain valves: 7) One detachable Ladder stair, SUS304 |

| optional |

Capacity:50-20000L Top hop additional port CO2 stone |

Please Note:

This fermenter comes complete with all valves, gauges and everything else a conical needs to operate, so it is as simple as fitting it into your brine lines and giving it a controller and start using. Other suppliers sell the tanks but not all the other gauges and valves to be able to plug in and start using the Unitank.

Accersories:

Welding and polish:

Polishing: Polishing is vital for tanks. Tanks should be polished wholly inside and outside.

Therefore it can ensure there is no place for the bacteria to hide in tanks.

Our polishing system consists of auto and semi-auto polishing machine and manual polishing.

Each tank is polished three times and more polish for the key place.

Welding: Our argon central system for welding provides 100% pure argon to protect tanks from

distorting during welding.

We also can custom make any tank to meet your brewery’s space and height restrictions.

Provide spare parts free of charge.

Provide installation and training services.

We consider all different potential situation in the delivery, so we use every prevention measures to avoid any potential inconvenience or trouble

Bulk cargo: Standard wooden case which can avoid any clash during the sea or air transportation in case of causing damage to the surface of our products.

Container cargo: the equipment will be bound firmly and won’ t easily swing to the side, or up, or down.50 / 500 / 1000 gallon stainless steel beer conical fermentation tank

1.Dedicated team of consulting services within 12 hours' reply

We have a whole well trained marketing team to provide the most userfriendly consulting services to

customers before they make decisions. Your questions would be replied within 12 hours by our sales

team.

2.Professional team of technical engineers

We have the most professional team of engineers for project design, equipment selection, system utilization, all of which make sure that the brewery system are up to customers’ satisfaction.

3.Industry leading manufacturing facilities

We have the most complete production line for equipment construction and state-of-the art manufacturing machines.

4.Warranty

Provide 36 months complete warranty for tanks body and lifetime maintenance service;

All of the accessories and auxuliaries facilities are guaranteed for one year.1000

gallon conical fermentation tank

shandong yuesheng beer equipment2is specialized in conical fermentation tank designing, manufacturing,installation, commissioning, technology and development services manufacturer. The company's production, technology,management of experienced professionals are constituted to excellent performance,exquisite workmanship, appearance concise atmosphere, the design is compact, easy to learn for the purpose of manufacturing production equipment.

Equipment is with UL/CE/ISO .

Advantage

Professional Beer Equipment manufacture with 10 years experiences in China.

Dedicated team of consulting Services&Professional team of technical engineers

Complete quality control and management systems

3 Years After-sales services for our goods.

Complete beer line to meet different capacities and all kinds of beer

Customize machine can be offered (voltage, material, dimension, heating source and so on);

1.What is kind of your packging?

Export standard, wooden case, iron crate, or any suitable for long distance sea transportation.

2.How long is your deliever lead time?

After 30-45 working days when we receiving your payment.

3.Could you caculate the shipping for me?

Yes, please kindly let us know which port is nearest your place.

4.Can your factory produce products according to our samples or drawing?

Yes, we can and most of our products can be customerized.

5.What is your term of payment?

50% T/T in advance ,balance before shippment. or other suitable payment methods.

How to make an order?

1.Send one inquiry or email

2.check email and choose models in our catalogue

3.negotiate detail order

4.confirm proforma invoice and arrange deposit

5.30-45 days later get your equipment

-

New WiFi Guten 40L 50L 70L Anti-burn Home Brewing All-in-one Micro Brewery/Craft Beer Machine/Brewery Equipment

-

500L 1000L Household Commercial Beer Fermentation Equipment Brewery Brewery Equipment Beer Brewing Equipment

-

China Micro Brewery Equipment Supplier

-

3x20" Ribbon Wrap Heating Pad Warming Heater Band for Kombucha and Beer Brewing

-

High quality 5l 10l 20l translucent fermenting barrel brewing beer container with air lock for home use

-

ethanol production machinery in small capacity medical alcohol production plant

-

stainless steel olive oil storage tanks

-

Alcohol copper still whiskey distillation column with helmet for sale

-

Automatic Fermentation Barrel Venting Household Fruit Beer Enzyme Container with 2 Lids Plastic Fermentation Tank

-

For sale pilot micro craft beer producers 100 200 400 500 1000 2000 l liter 2 3 5 7 20 bbl system equipment for drinking beer