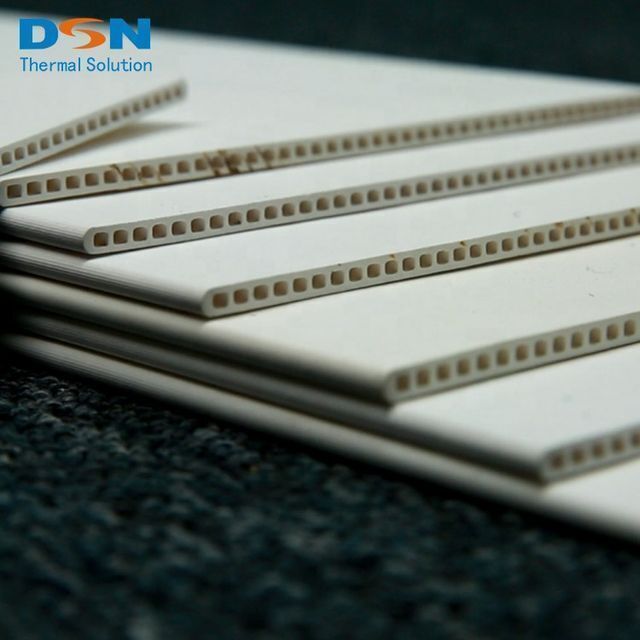

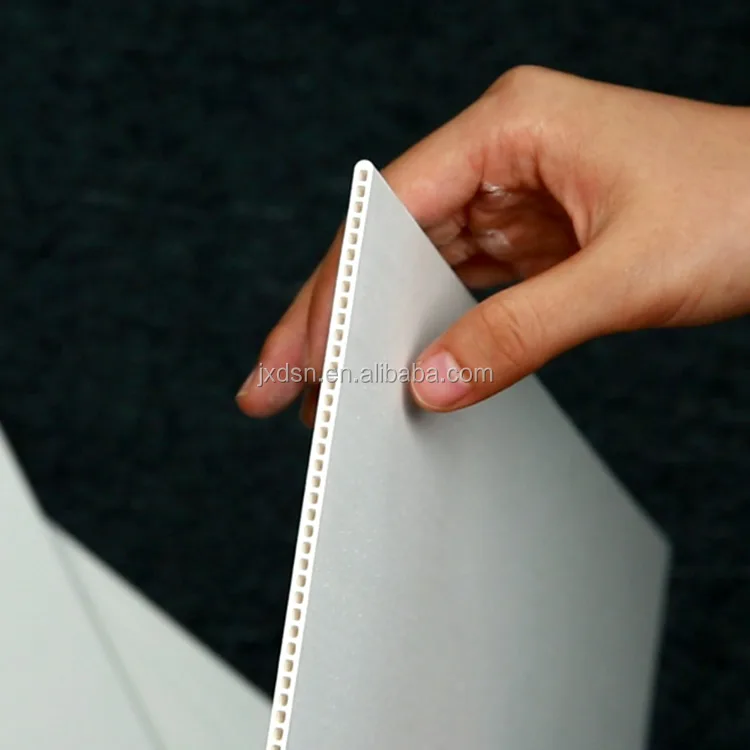

New wastewater treat ceramic ultrafiltration membrane filter plate

-

Supplier: Jiangxi Dasen Technology Co., Ltd. -

Region: Jiangxi, China -

Contact: Ms Cindy Dasen -

Price: $22.50 / 1 - 9 pieces

$22.05 / 10 - 99 pieces

$20.70 / >=100 pieces -

Min. Order: 1 piece

| Temperature: | 10~75 ℃; | Power: | /; |

| Selling Units: | Single item; | Filtration: | Negative pressure suction filtration; |

| Package Preview: | ; | After Warranty Service: | Video technical support,Online support,Spare parts; |

| Weight: | 0.5kgs; | Warranty: | 1 Year; |

| Marketing Type: | Ordinary Product; | Core Components: | flat ceramic membrane; |

| Water channel: | 43 pcs; | Brand Name: | NanoMem; |

| Membrane area: | 0.15 m2; | Productivity: | 50L/Hour; |

| Applicable Industries: | Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Retail,Construction works ,Energy & Mining,Municipal wastewater; | Material: | Aluminium Oxide,Foam film; |

| Video outgoing-inspection: | Provided; | Packaging Detail: | 1) PET film covered--protection; 2) Use paper card to separate each layer; 3) Standard export carton or customized; 4) Marked with customer's information or customized.; |

| Size: | 150*510*4mm; | Machinery Test Report: | Provided; |

| After-sales Service Provided: | Video technical support,Online support; | Max. Pressure: | 0.3 MPa; |

| Product name: | ceramic filtration membrane; | Warranty of core components: | 1 Year; |

| Porosity: | 35%; | Place of Origin: | Anhui China; |

| Weight (KG): | 0.5; | Showroom Location: | None; |

| Single gross weight: | 2.0 KG; | Single package size: | 62X20X9 cm; |

| Local Service Location: | None; | Bending strength: | 70 MPa; |

| Condition: | New; | Nominal pore size: | 0.1μm; |

Model | PCFM-A-20-3-U | PCFM-A-50-3-U | PCFM-A-100-3-U | PCFM-A-1U-3-M | |||

Formation | Plate | ||||||

Filtration | Negative pressure suction filtration | ||||||

Materials | Alpha-Al2O3 | ||||||

Water channel | 43 pcs | ||||||

Channel dimension | 2*3 mm | ||||||

Dimension | 150*510*4 mm | ||||||

Net weight | 0.44 kg | ||||||

Membrane area | 0.15 m2 | ||||||

Max. Pressure | 0.3 MPa | ||||||

Temperature | 10~75 ℃ | ||||||

Nominal pore size | 0.02 µm | 0.05 µm | 0.1 µm | 1 µm | |||

Porosity | 30% | 34% | 35% | 40% | |||

Pure water flux | 20 m3/Day | 20 m3/Day | 100 m3/Day | 200 m3/Day | |||

Bending strength | 80 MPa | 70 MPa | 70 MPa | 70 MPa | |||

Model | NM303 | NM703 | NM705 | NM710 | |||

Frame materials | SS 304 | SS 304 | SS 304 | SS 304 | |||

Pipe materials | UPVC | UPVC | UPVC | UPVC | |||

pH | 2~12 | 2~12 | 2~12 | 2~12 | |||

Membrane dimension, mm | W150×H310×T4 | W150×H510×T4 | |||||

Membrane material | Alpha-Al2O3 | ||||||

Membrane area, m2 | 3 | 30 | 50 | 100 | |||

Quantity of membrane, Pcs | 34 | 204 | 340 | 680 | |||

Capacity, m3/d | 2~4 | 20~30 | 40~50 | 80~100 | |||

MLSS, mg/L | 3,000~12,000 | 3,000~12,000 | 3,000~12,000 | 3,000~12,000 | |||

Confluence pipe diameter, mm | 32 | 50 | 75 | 75 | |||

Width, mm | 400 | 665 | 665 | 665 | |||

Length, mm | 600 | 760 | 1289 | 1289 | |||

Height, mm | 470 | 1978 | 1616 | 2590 | |||

Weight (dry), kg | 28 | 150 | 250 | 450 | |||

Corporate vision: lead innovation and services, help customers create competitiveness.

Enterprise mission: cultivate talents and make dedication

Business idea: people-oriented, customer first, continuous creation, pursuit excellence.

Environmental policy: full participation, compliance with laws and regulations, treasure resources.

Q1: Do you have MOQ?

A1: No MOQ for the standard product.

Q2: Do you provide samples?

A2: Yes, we do, and could delivery in 24 hours after confirmation for stock.

And we can offer free samples within one pcs. Just please pay the shipping fee.

Q3: Are you factory or trading company?

A3: We are a professional manufacturer for over 10 years.

Q4: What is the lead time for mass production?

A4: The lead time of mass production is about 5 - 7 days.

Q5: What is your payment method?

A5: Accept TT, Paypal, West Union, L/C, ect.

Q6: Can you provide finished product processing service?

A6: Yes, we can provide the finished product after die-cutting.

-

RUNXIN water softener control valve fully automatic multi-port flow control multi-filtration control valve

-

Small factory water treatment equipment groundwater well water reverse osmosis machinery RO filter mineral water manufacturing machine

-

Reclaimed water recycling system Car wash water recycling system Car wash reclaimed water system Laundry room reclaimed water recycling system

-

High output automatic five gallon filling machine equipment/drinking water filter

-

Water filling station / pure water vending machine for sale

-

Hot Water Softener Ion Exchange Resin for Ion Exchange Resin Tank

-

100 Gallon -- 5000 Gallon PVC Portable Water Storage Tank For Sale

-

Hotsale Medical Ozone Machine Kit Home Clinic Use Therapeutic Medical Ozone Generator

-

Household water purifier system 5/6 stage reverse osmosis system

-

500L/hour 1000L/hour water purifier osmoseurs 5 cassette ro water system Reverse osmosis system Sea water desalination plant