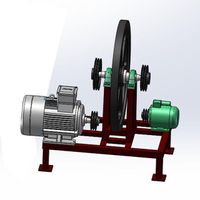

Manufacturer overmolding OEM u groove plastic small pulley wheels for rope

-

Supplier: Zhongde (Beijing) Machinery Equipment Co.,Ltd -

Region: Beijing, China -

Contact: Ms Linda Lee -

Price: $0.20 / >=100 pieces -

Min. Order: 100 pieces

Product details

| Density: | 0.9-2.5g/cm3; | Working temperature: | -60~350℃; |

| Place of Origin: | Hebei China; | Size: | As per customer's request; |

| Port: | Tianjin,Shanghai,Guangzhou,Beijing,Qingdao and etc; | Color: | Black,white,red,green or any color according to Pantone colors; |

| Warranty: | 3 years; | Payment Terms: | L/C,Western Union,T/T; |

| Tolerance: | ±0.05mm; | Brand Name: | Zhongde; |

| Applicable Industries: | Hotels,Garment Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Advertising Company; | Hardness: | Shore D; |

| Processing Technic: | CNC machining,injection molding & extrusion; | Drawing Format: | DWG/DXF/IGS/STEP/X-T and PDF; |

| Material: | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc.,Plastic; | Customized support: | OEM,ODM; |

| Package Preview: | ; | Supply Ability: | 50000 Piece/Pieces per Day; |

| Item: | OEM u groove plastic small pulley wheels for rope; | Type: | u groove; |

| Packaging Detail: | In general,we use ziplock bag or bubble film plus cardboard boxes, and wooden pallets or wooden cases will be used if necessary.; |

Our Services

Product Design

Mold Design

Bulk Production

Surface Treatment

Packaging

Material Selection

Mold Making

Logo Printing

Assembling

Door to Door Delivery

Product Description

Item | plastic pulley/poleas de plastico |

Material | Nylon ,mc nylon, POM,ABS,PU,PP,PE,PTFE,UHMWPE,HDPE,LDPE, PVC,etc. |

Color | Black, white, red, green, transparent or any color according to Pantone code |

Size | As per customer's requirements |

Technology | Injection molding, CNC machining, Extrusion. |

Surface Treatment | Powder coating, Zinc coating, Galvanization, Electro-deposition coating, Chrome/zinc/nickel plating, Polishing, Silkscreen, Black oxide |

Application | Automotive, ATV, Mechanical equipment, Construction, Home appliance, Aviation, Office facilities, Agriculture, etc. |

Shippment | We have longterm cooperation with internation shipping agent and express company, so that shipping safty and arriving time are secured |

Company Profile

Zhongde is a leading manufacture of OEM parts in rubber & plastic & metal parts. We are always pursuing providing better quality products in shorter period. With a knowledgeable team which has experience in molding and production, we are confident to help you develop and manufacture your product

We have different types of machines to meet different requriements. Most our machines were imported from overseal. The highest rotate speed of CNC machining center can reach to 20,000RPM. The largest vulcanize rubber machine can produce rubber parts within 3000mm.

CNC Lathe Center

Precision Machining Center

Vertical Machining Center

WEDM

EDM

Injection Molding Machine

Large Flat Vulcanizing Machine

Automatic Vulcanizing Machine

Vulcanizing Injection Machine

Product Range

Zhongde products range from mold to rubber & plastic & metal parts. We can also design drawing according to its applications or customers requirement.

Rubber Parts

Plastic Parts

Polyurethane Parts

CNC Machining Parts

Recommend Products

Vacuum Suction Pad

Plastic Injection Cover

Rubber Roller

Vibration Mount

Silicone Button

Rubber Bellow

CNC Plastic Block

Plastic Gear

Rubber Solid Ball

Metal Punching Parts

Rubber Impeller

Rubber Buffer

Sealing Gasket

Plastic Pulley Wheel

Plastic Enclosure

Rubber Handlebar Grip

Rubber Furniture Feet

Suction Cup

Customer Photos

Packing & Shipping

Packaging

Normally the goods are packaged as the picture shows, or it can be as customized.

Shipping

We will discuss with our customers to choose the suitable shipping method for goods.

FAQ

Q1. Are you factory or trade company?

A: We are both, we have our own factory and we can export by ourself.

Q2. What kind of payment do you accept?

A: Trade assurance, T/T, L/C, Weston Union are all accepted.

Q3. What is normal lead time?

A: Average 15-25 days for tooling, bulk orders should be depends on quantity.

Q4. What is your standard package?

A: In general we use ziplock bag or bubble file plus cardboard boxes, wooden pallets or wooden cases will be used if necessary,. Special packing method is available if needed.

Q5. What is the working life of the mould?

A: It depends on the parts we made. Besides, we will maintain or replace the mould be ourselves.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

VIEW MORE

You may like

-

Pulley Custom Free Energy Generator Cast Iron Flywheel Pulley 20kg 40kg, 50kg, 65kg 100kg, 200kg 5KW 10KW 15KW

-

Free Sample Solid Durable Plastic Nylon OD 50mm Fitness Equipment Accessories In Stock Gym Pulleys

-

Textile ceramic accessories winding machine wire wheel integral ceramic guide wheel alumina ceramic wheel

-

6202 High Quality Forged Steel Bearing Wheels 64mm Wire Rope Crane Pulley

-

Stainless steel 304/316 single double wheel pulley swivel eye wire rope pulley

-

Home Exercise Bike 193mm 200mm Pulley Nylon Fiber Belt Pulley

-

Single Nylon Pulley String Pulley Blocks for String Conductors

-

Reasonable price 8.1*52*22 baby carriage plastic moving wheels nylon plastic moving wheels

-

China factory price SPZSPAPBSPC cast iron V pulley with conical bush for ari machine fan pump

-

Custom Powerless Generator Cast Iron Flywheel for 40kg, 50kg, 65kg 100kg, 200kg

Other Products

-

$0.10 / piece

$0.10 / piece -

$0.35 - $0.65 / piece

$0.35 - $0.65 / piece -

$0.10 / piece

$0.10 / piece -

$0.10 / piece

$0.10 / piece -

$0.10 / piece

$0.10 / piece