Hongteng 8-32mm capacity 3-15T/Hour Reinforced angle bar deformed steel bar iron rod making machine

-

Supplier: Luoyang Hongteng Electrical Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms michelle woo -

Price: $45000.00 /set -

Min. Order: 1 set

Product details

| Local Service Location: | Egypt,Viet Nam,Indonesia,Russia,Kazakhstan,Kyrgyzstan,Uzbekistan; | power: | depend on production yield; |

| Warranty of core components: | 1 Year; | Power: | Not-standard; |

| After Warranty Service: | Video technical support,Online support; | Machinery Test Report: | Provided; |

| Condition: | New; | Weight: | Not-standard; |

| Package Preview: | ; | Video outgoing-inspection: | Provided; |

| Showroom Location: | Viet Nam,Indonesia,Russia; | After-sales Service Provided: | Engineers available to service machinery overseas,Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; |

| Voltage: | Not-standard; | Port: | shanghai,tianjin,qingdao ,guangzhou; |

| Place of Origin: | Henan China; | Type: | Hot Rolling Mill; |

| Payment Terms: | L/C,Western Union,D/P,D/A,T/T,MoneyGram,cash; | NAME: | steel bar making machine; |

| Applicable Industries: | Building Material Shops,Manufacturing Plant,Construction works ,Energy & Mining; | raw material: | scrap steel or steel billet; |

| Supply Ability: | 3000 Set/Sets per Year iron rod making machine; | part3: | cooling bed; |

| capacity: | 3-15 ton per hour; | Marketing Type: | New Product 2020; |

| Brand Name: | Hongteng; | Warranty: | 1 Year; |

| part 1: | melting furnace or steel billet reheating furnace; | Packaging Detail: | Standard export cases for packing steel rebar making machine Together with below documents: 1. packing list, 2 originals 2. invoice, 2 originals 3. bill of lading, 4. certificate of origin; |

| part 2: | hot rolled machine; | Certification: | ISO CE BV; |

| Core Components: | Hot rolling mill; | Dimension(L*W*H): | Not-standard; |

| Key Selling Points: | Competitive Price; |

8-32mm capacity 3-15T/Hour Reinforced deformed steel bar iron rod making machine

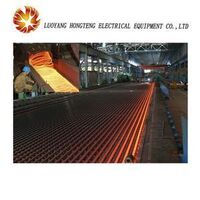

Product Show

1. The continuous rolling mill is an advanced method which can improve labor productivity and rolling type, mainly used in iron and steel plants to produce section bar, wire rod, steel bar, channel steel, flat bars, steel plates and other products. The raw material is steel scrap or billet (40-120mm).

2. The continuous casting and rolling production Line generally suitable for capacity of 5- 20t/h.

3. The diameter of the steel bar of the final product: 6.5-32mm, the length: 3000-12000mm.

2. The continuous casting and rolling production Line generally suitable for capacity of 5- 20t/h.

3. The diameter of the steel bar of the final product: 6.5-32mm, the length: 3000-12000mm.

Project site

1, By using metallurgical heat energy of continuous casting blanks, 30% of energy consumption can be saved.

2, Simplify the production process, reduce the plant area of factory and save the cost of infrastructure construction.

3, Greatly shorten the production cycle, improve the quality of products

2, Simplify the production process, reduce the plant area of factory and save the cost of infrastructure construction.

3, Greatly shorten the production cycle, improve the quality of products

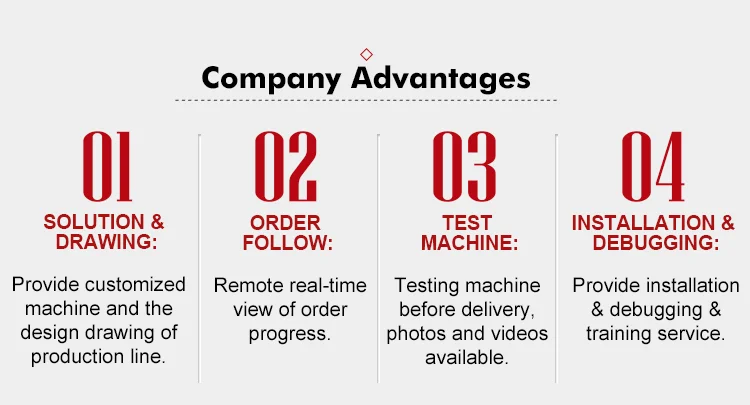

1, Provide overall solution and after-sales guarantee

2, Provide plant design, proposal, manufacturing, shipping, installation and commissioning services

3, Provide factory building design, overall equipment layout, rolling mill process design, electrical circuit layout and other services.

4, Dispatch technicians to provide installation services after the machine arrives until the customer is satisfied

5, Long-term technical support, long-term machine warranty

2, Provide plant design, proposal, manufacturing, shipping, installation and commissioning services

3, Provide factory building design, overall equipment layout, rolling mill process design, electrical circuit layout and other services.

4, Dispatch technicians to provide installation services after the machine arrives until the customer is satisfied

5, Long-term technical support, long-term machine warranty

Specification and Technical Parameter | ||||||||

Capacity(T/Hour) | Working hours(Year) | Electricity consumption | Feed section (MM) | Rebar diameter | ||||

5 | 2400 | 5MW | 60*60 | Ø8-16 | ||||

8 | 2400 | 8.5MW | 70*70 | Ø8-24 | ||||

10 | 3600 | 9.5MW | 90*90 | Ø8-32 | ||||

15 | 3600 | 10MW | 120*120 | Ø8-32 | ||||

16 | 6000 | 15MW | 120*120 | Ø6.5-32 | ||||

35 | 6000 | 26MW | 150*150 | Ø6.5-32 | ||||

Recommend Products

Why Choose Us

We can give customer one APP account, Customer can use their phone or computer to view order progress in real time

Certifications

Product packaging

VIEW MORE

You may like

-

Various narrow strip mills in steel re-rolling mills

-

120mm/160mm goldsmith sheet semicircle pattern wire roller silver gold electric mill for jewelry making machine

-

Continuous Casting Machine Rebar Manufacturing Machine Rolling Mill Production Line

-

Gear Ratio 1:2.5 Manual Wire Rod Tablet Press Jewelry Gold Jewelry Two Roller Rolling Mill Mill Jewelry

-

4" Benchtop Combined Plate and Wire Rod Mill Motorized and Manually Operated

-

Floor Standing Combined Plate and Wire Goldsmiths Jewelry Rolling Mills for Gold, Silver, Copper, Brass, Plate and Wire

-

6-high five-stand cold rolling mill/1450mm 6-high cold rolling mill

-

Indian Jewelry Gold and Silver Sheet and Wire Rolling Machine Precision Sheet and Wire Rolling Factory

-

1450 Aluminum Caster Casting Machine to make 1250mm wide and 6mm thick aluminum sheet rolling mill

-

High quality programmable screw machine EZSO GP-100T, max width 680mm, bending machine

Other Products

-

$43000.00 / set

$43000.00 / set -

$40000.00 / set

$40000.00 / set -

$50000.00 / set

$50000.00 / set -

$20000.00 / set

$20000.00 / set -

$999.00 / set

$999.00 / set -

$20000.00 / set

$20000.00 / set -

$20000.00 / set

$20000.00 / set -

$999.00 / set

$999.00 / set