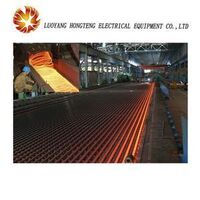

Hot rolling mill steel bar production line manufacturer rebar making machine

-

Supplier: Luoyang Hongteng Electrical Equipment Co., Ltd. -

Region: Henan, China -

Contact: Ms michelle woo -

Price: $20000.00 /set -

Min. Order: 1 set

| Packaging Detail: | Standard export cases for packing steel bar production line rebar production line; | Type: | Hot Rolling Mill; |

| Voltage: | 380V; | Place of Origin: | Henan China; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Video technical support,Online support; | part 1: | melting furnace or steel billet reheating furnace; |

| Power(W): | 500KW; | Certification: | ISO,CE; |

| Warranty: | 1 Year; | power: | depend on production yield; |

| NAME: | steel bar production line; | part 2: | hot rolled machine; |

| Condition: | New; | Port: | shanghai,tianjin,qingdao ,guangzhou; |

| capacity: | 5 /10/15 ton per hour; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,cash; |

| Supply Ability: | 3000 Set/Sets per Year steel bar production line; | heating furnace: | electric heating or gas heating; |

| part3: | cooling bed; | Brand Name: | hognteng; |

| raw material: | scrap steel or steel billet; | Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; |

| part 4: | packing table; | area: | 10*20m; |

Hot rolling mill steel bar production line manufacturer rebar making machine

If you want to produce steel bar/rebar, please contact us!

We can provide complete production equipment!

Free provincial technology!

Features of our steel bar production line:

1. Hot steel billet rolling mill

2. Turnkey project of complete line

3. Powerful working team and technology support

4. Cooperated with Best China Metallurgical Design Institute

5. Excellent user achievement and good positive feedback

6. Very challenging project quotation

7. Lifelong after-sales & maintenance support

Our company supply all kinds of steel wire /rebar/ flat bar/angel steel/H steel / steel bar production line productivity

two types Steel production line:

1. Raw material is scrap steel iron

waste steel ----melting---- casting----mold unloading----sorting-----deliver to heating furnace----heating to 1150 degree to 1200 degree----- come out furnace----- rolling----- finished product ----packing---- sales

2. Raw material is steel billet

Steel billet ------Feed into furnace----- electric induction heating furnace ------feeding out of furnace---run in rolling table-----roughing rolling mill--run out lifting rolling table ------continuous rolling mills----Cooling bed input rolling table--chain type cooling bed----cut into Fixed-length -packing table

Covering area: 20m*100m, Transformer capacity:3000KVA

5T/hour productivity, we suggest customer use 60*60 steel billets,this mainly decide cost of rolling mill.

PART 1: heating furnace

Heating energy can use natural gas or heavy oil as medium, or electric heating.

1). Gas heating save cost , but it is suitable for continuous 24 hours working

2). If every day Intermittent work, for example, work 5hours, 8-10 hours, recommend you electric heating furnace, is more suitable .

For example, use electric induction heating furnace 2300KW, heating capacity : 5.2ton per hour. The steel billet is fed into heating furnace, through feeding mechanism ,by automatic hydraulic type push steel billet , to be heated.

Technical parametes of steel billet electric heating furnace for steel bar production line

Model KGPS-3000 | Technical parameters |

Rated power | 2300KW |

Hydraulic push steel billet machine | 10 T |

Heating furnace body | Customized for 60*60 steel billet

|

Water cooled cable | 2 PCS |

Discharging mechanism | mechanical |

Rated frequency | 500HZ |

Rated temperature | 1250℃ |

Generator specification | KGPS-2300-0.5 |

The heating quality of the blank directly affects the energy consumption of the heating furnace, the life of the rolling mill, and the output and quality of the finished product.

The heating process of the blank mainly includes:

Billet heating temperature ,Billet heating time,

Billet heating speed ,Billet heating uniformity,

Based on theoretical calculations and actual production experience, the billets should be continuously heated to 1050 to 1150°C in the furnace.

PART 2 : Rolling mills

2.1.Rough rolling mills

The steel billet heated by the heating furnace is pushed out by the auto hydraulic type push steel billet machine one by one, and is fed into the Φ350 three-high mill through feeding out of heating furnace roller path and the run in rolling table.

2.2.use 3 groups Φ250×2 two-high mills ,one drag two (one group has two racks) continuous rolling mills.

PART 3.Cooling bed

Cold Beds and Finished Products

The rolled part with the finished section enters into the cooling bed input track.

The rolling stock continues to lead to a 3000KN cold shearing machine, which is cut to a length of 6 to 12 meters by means of a sizing machine. After the sheared steel is inspected on the inspection bench, the fixed-length and non-sizing steels are placed in the finished product collection basket.

Auxiliary equipment

1. Run in rolling table before roughing mill 1set

Run out lifting rolling table 1 set

2. pinch roller 1set,

3. Swinging head scissors 1 set

4. Chain type cooling bed 1 set(40×4M)

5. 100 Hydraulic metal cutting machine 1set

6. feeding (Run in )rolling table,rolling table come out of from cooling bed,rolling table after shear

The biggest advantages : We provide turnkey project

Seller will dispatch engineer to supply installation & debugging service till machine normal production.Seller will training buyer's workers to operate machine & normal daily maintenance.

Buyer pay seller engineer USD100/day/person.Buyer responsible for seller engineer‘s visa,round-trip tickets,accommodation,food.

ISO CE certificate

Before sales

Our professional technical recommend the right machine,and can also customise special machine as customer's requirement and special parts.

Sales following

During machine production, watching the machine quality and testing machine.and take pictures or make video for customer checking.

After Sales

We will send technical go to customer's factory to install and adjust machine.

We have after-sell service center in Vietnam and Indonesia,to supply all life-time machine maintance and repairment service

If you are intertested in steel bar /rebar production line ,please contact us !

We will provide you the whole solution and reasonable price .

-

Various narrow strip mills in steel re-rolling mills

-

120mm/160mm goldsmith sheet semicircle pattern wire roller silver gold electric mill for jewelry making machine

-

Continuous Casting Machine Rebar Manufacturing Machine Rolling Mill Production Line

-

Gear Ratio 1:2.5 Manual Wire Rod Tablet Press Jewelry Gold Jewelry Two Roller Rolling Mill Mill Jewelry

-

4" Benchtop Combined Plate and Wire Rod Mill Motorized and Manually Operated

-

Floor Standing Combined Plate and Wire Goldsmiths Jewelry Rolling Mills for Gold, Silver, Copper, Brass, Plate and Wire

-

6-high five-stand cold rolling mill/1450mm 6-high cold rolling mill

-

Indian Jewelry Gold and Silver Sheet and Wire Rolling Machine Precision Sheet and Wire Rolling Factory

-

1450 Aluminum Caster Casting Machine to make 1250mm wide and 6mm thick aluminum sheet rolling mill

-

High quality programmable screw machine EZSO GP-100T, max width 680mm, bending machine

Other Products

-

$43000.00 / set

$43000.00 / set -

$45000.00 / set

$45000.00 / set -

$40000.00 / set

$40000.00 / set -

$50000.00 / set

$50000.00 / set -

$20000.00 / set

$20000.00 / set -

$999.00 / set

$999.00 / set -

$20000.00 / set

$20000.00 / set -

$999.00 / set

$999.00 / set