Automatic dry mix mortar 5-8t/h ceramic tile adhesive mixing machine

-

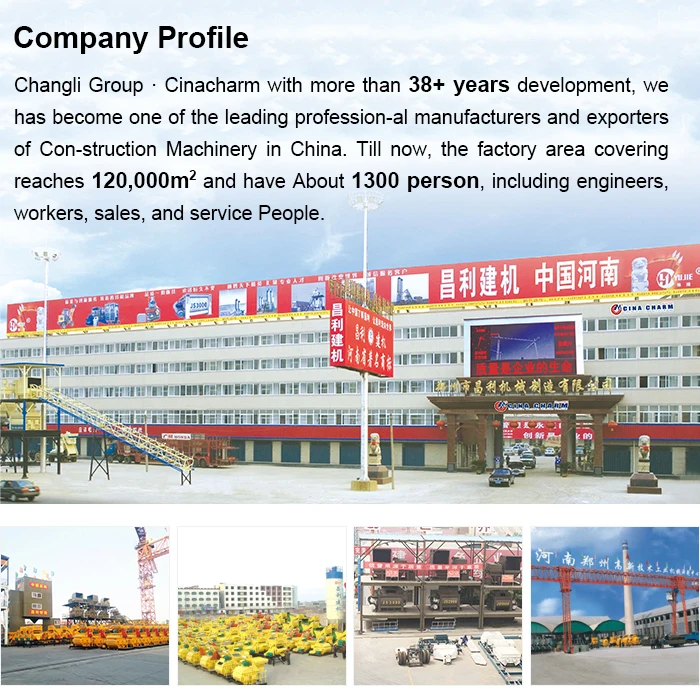

Supplier: Zhengzhou Changli Machinery Manufacturing Co., Ltd. -

Region: Henan, China -

Contact: Ms Vivian Chen -

Price: $7000.00 /set -

Min. Order: 1 set

| Port: | China mainly port; | Key Selling Points: | Easy to Operate; |

| Features: | Simple,High tec; | Condition: | New; |

| Local Service Location: | None; | silo: | 1.8*2.8m; |

| Hoop: | 165mm; | Feeding screw conveyor: | 165*3m; |

| Warranty of core components: | 1 Year; | Brand Name: | Cinacharm; |

| Voltage: | 220/240/380/415/440/450V; | Color: | As request; |

| Showroom Location: | None; | Application: | Dry Mortar mixing; |

| Core Components: | Motor,Gear; | Name: | Automatic dry mix mortar 5-8t/h ceramic tile adhesive mixing machine; |

| Weight: | 2200kg; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| After-sales Service Provided: | Online support,Video technical support; | butterfly valve: | 165mm; |

| LOGO: | As request; | Marketing Type: | Hot Product 2019; |

| Power: | 22Kw; | Place of Origin: | Henan China; |

| Package: | Impeller pallde packing machine; | Machinery Test Report: | Provided; |

| Certification: | CE ISO BV; | Warranty: | 1 Year; |

| Packaging Detail: | 1)FCL: in nude for standard exporting container 2)LCL: Poly wood case Wire cables are used for fastening the machine Cork wood are placed in front or behind the machine to protect it. Plastic film is covered on the machine as a rain-roof. Crane is used during the whole loading.; | mixer: | 3.3mX1.15mX2.15m; |

| Supply Ability: | 50 Set/Sets per Month; | Video outgoing-inspection: | Provided; |

| After Warranty Service: | Video technical support,Online support; | Applicable Industries: | Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Construction works ,Energy & Mining; |

| Dimension(L*W*H): | 6136x3057x3285mm; |

Automatic dry mix mortar 5-8t/h ceramic tile adhesive mixing machine

Introduction of Mortar Manufacturing Machinery

I. Additionally equipped with secondary screw conveying system, finished product storage silo, automatic packing machine based on multi spiral ribbon mixer, to composed an efficient and reasonable simple dry powder mortar mixer with low cost.

II. Occupation Area<20m2, Height <3.5m, its capacity at 25-30t per day, just only need 2-3 person,very easy to operate.

Main Features of Mortar Manufacturing Machinery

1) Small investment and best for individuals.

2) Small footprint, ordinary houses can build the factories.

3) Easy to operation, 2-3 people can make it. .

4) High yield, the output is 3-4T/H usually, to reach 20-25T per day.

5) Easy to operation and maintenance.

|

Model |

1T dry mortar line |

|

Dust cover |

One set |

|

First feeding machine |

Diameter: 165mm |

|

|

Length: 3.2m |

|

|

Power: 3kw |

|

Soft connection for the first feeding machine |

One set |

|

Hoop |

One set |

Question I.What is the function of the concrete batch plant?

Answer: It is used to produce all kinds of concrete to meet the building work of buildings,bridges,dock,airport, railway,etc

Question II. How to choose the suitable model of batch plant?

Answer:Just tell us the capacity (m3/h,t/h)of concrete you want to produce concrete per hour or per month.

Question III.What paymet terms you use?

Answer:Usually the world most common used T/T,L/C ,etc

Question IV. Do you supply other products?

Answer:Yes, we have . please see the following chart :

| NO. | Product Name | Type |

| 1 | Concrete Batching/Mixing Plant | Fixed and Mobile |

| 2 | Concrete Mixer | Twin Shaft, Single Shaft, Rotating Drum Type |

| 3 | Stabilized Soil Mixing Station/Plant | Station and Mobile |

| 4 | Asphalt Mixing Plant | From LB500 to LB4000 |

| 5 | Dry-mix Mortar Production Line | Full-auto |

| 6 | Concrete Batching Machine | Accumulative Weighing Type, Separater Weighing Type |

| 7 | Cement Silos | Fixed and mobile |

| 8 | Screw Conveyors | With universal joint |

| 9 | Concrete Mixer Truck | From 3m3 to 16m3 |

| 10 | Concrete Pump | Electric type and diesel engine powered |

| 11 | Brick Making Machine | Manual, Electric, Diesel |

| 12 | Wheel Loaders | ZL06-ZL50 |

| 13 | Construction Elevators | Single Cage and Double Cage |

| 14 | Tower Crane | stationary, mobile,outside-climbing, inside-climbing, horizontal-jib, luffing-jib, hammer-head, flat-top, |

Q1:How to use this dry mix mortar mixing plant?

A:As a professional dry mix mortar mixing plant manufacturer,we have many professional engineers, they will go to clients’ site for guiding the installation and test-running;also can teach you how to use the mixing plant properly.

Q2: What is the delivery time?

A: 30-50days after receiving advance payment

Q3: What is the payment terms?

A: T/T. L/C are all accept.

Q4: Do you have any cases abroad?

A: Yes, we imported to India, Vietnam,etc.

Q5: How many engineers do you have?

A: We have more than 30 engineers. when go to installation,have professional team to guide.

-

Cheap dry mortar mixer from China with high productivity

-

hot sale dry cement mixer for mixing sand and cement / automatic dry mortar production line equipment

-

Sincola Ready Mixed Gypsum Cement Tile Adhesive Mixer Glue Production Line

-

Toolmore 100 Liter Portable Concrete Mortar Mixer

-

cement sand mixing bagging machine cement mortar mixer

-

Simple caulk mixer production line

-

Low investment and high efficiency simple dry powder mortar production line

-

Small business tile adhesive machine price

-

Simple dry powder mortar production line cement mortar mixer wall putty mixing equipment tile glue making machine

-

Energy-saving equipment cement mortar mixing line mixer price