3Mm Thickness 2W Thermal Conductivity Thermal Conductive Pad For Cpu

-

Supplier: Shenzhen Union Tenda Technology Co., Ltd. -

Region: Guangdong, China -

Contact: Ms YN L -

Price: $0.05 / >=100 pieces -

Min. Order: 100 pieces

| Application: | CPU/IC/Computer/Battery etc.,LED IC chip heatsink PCB CPU; | Model Number: | LC200; |

| Packaging Detail: | Standard size of thermal pad: 200*400mm/ 300*400mm; Package :Standard Cartons; | Tensile Strength: | 588Mpa; |

| Color: | Blue; | Sample: | Freely Supplied; |

| Selling Units: | Single item; | Thickness: | 0.3~10mm; |

| Rated Voltage: | 5kv/mm; | Place of Origin: | Guangdong China; |

| Breakdown Voltage: | 10KV/mm; | Hardness: | 40~80; |

| Material: | Silicon; | Thermal Conductivity: | 2.0w/mk; |

| Standard size: | 200mm*400mm,300mm*400mm;Customized size available; | With Adhesive/Fiberglass/Silicone pad: | Support; |

| Single package size: | 10X10X10 cm; | Type: | thermal pad; |

| Brand Name: | LTD; | Single gross weight: | 0.05 KG; |

| Flame Rating: | V-0; |

3Mm Thickness 2W Thermal Conductivity Thermal Conductive Pad For Cpu

| Product Name | 3Mm Thickness 2W Thermal Conductivity Thermal Conductive Pad For Cpu |

| Model | LC200 |

| Color | Blue |

| Thickness | 0.3~10mm |

| Hardness | 40~80 |

| Specific Gravity | 2.5g/cm3 |

| Tensile Strength | 0.29Mpa |

| Elongation | 45% |

| Tear Strength | 0.9KN/m |

| Breakdown Voltage | ≥10KV/mm |

| Volume Resistivity | 5×1012Ω·cm |

| Continuous Use Temp | -40~200℃ |

| Flame Rating | V-0 |

| Weight Loss | ≤0.3% |

| Dielectric Constant | 5.69 |

| Thermal Conductivity | 2W/m·K |

| MOQ | 100 Pcs |

| Lead time | Within 1-3 working days |

| Payment | Paypal/WU/TT/Trade Assurance/Money Gram/Cash |

| Shipping | DHL/UPS/FedEx/Aramex/EMS/HK Post |

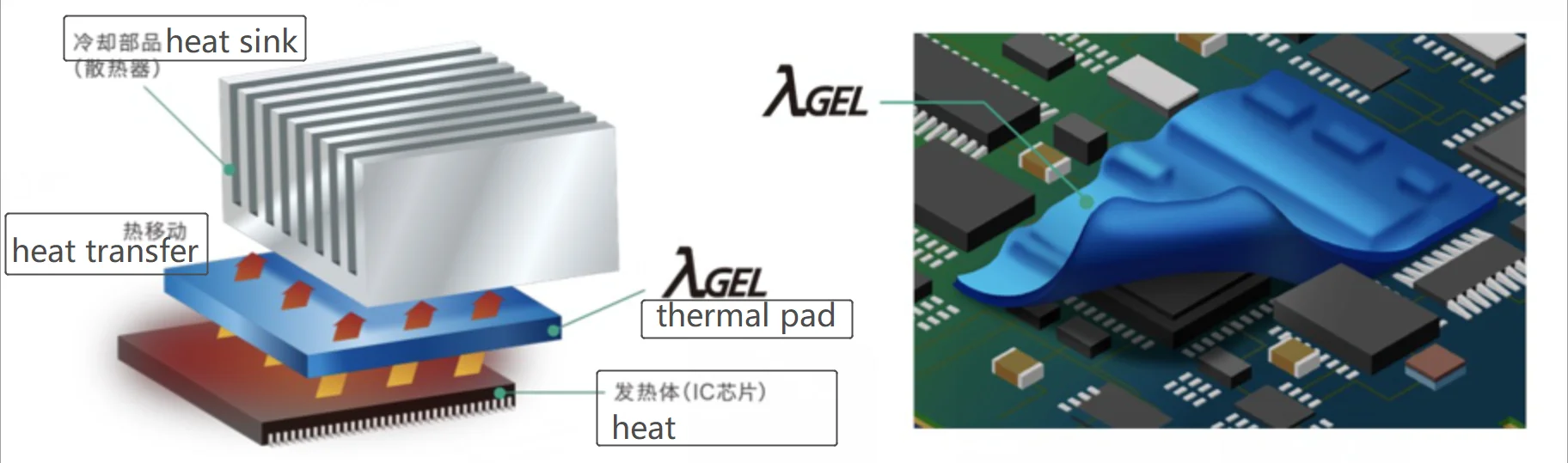

THERMAL CONDUCTIVITY THEORY

High Thermal Conductive Silicone Pad

High thermal conductive silicone pad is a high thermal conductivity material. The raw material is made of Japan Electrochemical High Thermal Conductive Spherical Alumina Powder and Dow Corning Polymer. It is a cost-effective thermal gap filling material. The surface's natural micro-viscosity and softness can well fill the air gaps to transfer the heat between the heat source and the heat sink to improve heat dissipation and improve the efficiency of heating electro-nic components and service life. It is an ideal thermal interface material.

Features & Benefits:

l Cost-effective, high conductivity, low thermal resistance

l Soft and flexible, reducing the interface thermal resistance

l High electrical insulation to protect electronic devices

l Natural sticky, easy application, reworkable

l Meet ROHS and environmental requirements

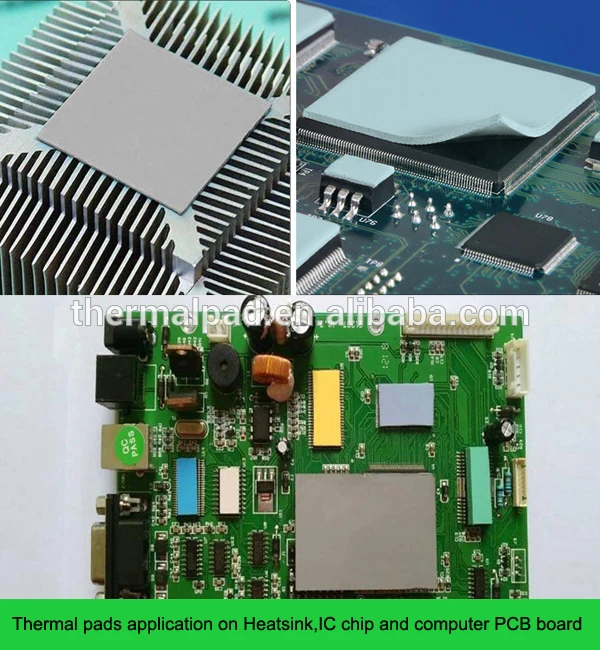

Typical Applications:

l High thermal conductivity module

l new energy vehicles

l Microprocessors, memory chips and graphics processors

l Network communication equipment

l Car equipment, charger

l High-speed hard disk drive

Physical Properties:

| Test Item | Unit | LC200 | LC300 | LC400 | LC500 | LC600 | LC700 |

| Color | - | Blue | Blue/Gray | Gray | Gray | Gray | Gray |

| Thickness | mm | 0.3~10 | 0.3~10.0 | 0.5~5.0 | 0.5~5.0 | 0.5~5.0 | 0.5~5.0 |

| Hardness | Shore 00 | 40~80 | 40~80 | 60~80 | 60~80 | 60~80 | 60~80 |

| Specific Gravity | g/cm3 | 2.5 | 3 | 3.24 | 3.32 | 3.43 | 3.5 |

| Tensile Strength | Mpa | 0.29 | 0.19 | 0.14 | 0.2 | 0.22 | 0.15 |

| Elongation | % | 45 | 40 | 32 | 60 | 16 | 24 |

| Tear Strength | KN/m | 0.9 | 0.9 | 0.7 | 0.5 | 0.5 | 0.5 |

| Breakdown Voltage | KV/mm | ≥10 | ≥10 | ≥5 | ≥7 | ≥7 | ≥7 |

| Volume Resistivity | Ω·cm | 5×1012 | 1×1012 | 1×1013 | 2×1013 | 2×1013 | 3×1011 |

| Continuous Use Temp | ℃ | -40~200 | -40~200 | -40~200 | -40~200 | -40~200 | -40~200 |

| Flame Rating | - | V-0 | V-0 | V-0 | V-0 | V-0 | V-0 |

| Weight Loss | % | ≤0.3 | ≤0.3 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

| Dielectric Constant | @1MHz | 5.69 | 7 | 6.75 | 7.92 | 7.47 | 8 |

| Thermal Conductivity | W/m·K | 2 | 3 | 4 | 5 | 6 | 7 |

SHENZHEN UNION TENDA TECHNOLOGY CO.,LTD is a high-tech enterprise which dedicated to the R&D, manufacture and sales of the thermal interface materials (TIMs). We have rich experiences in this field which can support you the latest, most effective and one -stop thermal management solutions. We have many advanced production equipments,full test equipments and fully automatic coating production lines which can support the production for high performance thermal silicon pad, thermal graphite sheet/ film, thermal double-sided tape, thermal insulation pad, thermal ceramic pad, phase change material, silicon caps, silicon tubes, thermal grease, bushing etc. UL94 V-0, SGS and ROHS are compliant. The TIMs are widely used for smart phone, LED light, power supply, laptop, tablet PC, household appliances and e-products. "Customer first, Sincerity based, Quality priority, Keep moving " is our operation principle, which help us build a first-class enterprise. Our priority quality is from on our scientific management model, professional technology and advanced production equipment. We are trying our best to develop the domestic and foreign market and build good business cooperation with you based on our reasonable price and high quality.

|

Our services |

|

1. 10 years TIMs experiences |

|

2. Professional R&D team |

|

3. One-stop service for thermal conductive material |

|

4. Support customized orders,including size,shape,color, and thermal conductivity or can be coated one side or two sides adhesive or fiberglass according to your demands |

|

5. Free sample provided |

|

6. Manufacturer offers best price |

|

7. Good quality and fast delivery |

|

8. Professional after-sale service |

|

9. Quality system to obtain ISO9001 certification,products meet ROHS,REACH and safety standard certification standards |

|

10. Prompt response within 24 hours |

Q1: What's the thermal conductivity test method given on the data sheet ?

application ?

Q4: Do you offer free samples ?

Q5: How to ship the orders ?

kindly tell us before shipping out.

-

2023 High Quality Thermalright ODYSSEY Gel Cooling 3mm Silicone Thermal Pad for CPU GPU RTX 3080 3090 Thermal Pad

-

11kv cold shrink terminal indoor end connector crimping power cable accessories

-

High Quality 2:1 Ratio Different Colors Well Insulated 600V Polyolefin Heat Shrink Tubing

-

Top Product Class E Slot Insulation Polyester Film Motor Insulation 6021 Milky White Insulation Film 6020 Mylar Film

-

PVC Electrical Insulation Tape for Wiring Harness

-

Battery Shrink Wrap Blue Pvc Heat Shrink Film Pvc Heat Shrink Tube For 18650 21700 32700 Battery Pack

-

3/4" x 10 yds. PVC Insulating Electrical Tape Globe VINI INDUSTRIES 1500 Lead-Free Pressure Sensitive Tape

-

Hot Sale Strong Adhesive High Quality Outdoor Cold Resistant Low Price Pvc Color Electrical Insulation Tape

-

Sale of OSAKA pvc electrical insulation tape in Nepal Afghanistan and Pakistan market

-

3:1 general-purpose heat shrink tubing with excellent physical and mechanical properties