5Tons new installed in UK for waste plastic to oil with distillation recycling

-

Supplier: Luoyang Ninca Environmental Technology Co., Ltd. -

Region: Henan, China -

Contact: Ms Ninca Ning -

Price: $18500.00 /set -

Min. Order: 1 set

| Steel: | Q345R stainless steel; | Machine name: | waste plastic to oil; |

| Marketing Type: | New Product 2020; | Package Preview: | ; |

| power: | 18-25KW/H; | pyrolysis time: | 9-14hours; |

| Machinery Test Report: | Provided; | Equipment Capacity: | 3-15tons/day; |

| heating method: | wood, coal, natural gas, fuel oil; | Weight (KG): | 15000; |

| raw material: | waste tyre ,used rubber , waste plastic; | Packaging Detail: | 1*40FR+1*40HQ for 8-12Tons capacity plant 3Tons plant is on the skid which need 1*40 top open container; |

| cooling method: | water; | Certification: | ce,ISO,Sgs; |

| Key Selling Points: | Energy saving; | Applicable Industries: | Manufacturing Plant; |

| Warranty: | 2 years; | Port: | shanghai, tianjin, lianyungang, qingdao; |

| Local Service Location: | None; | Video outgoing-inspection: | Provided; |

| Showroom Location: | None; | Supply Ability: | 25 Set/Sets per Month; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Brand Name: | ninca; |

| Core Components: | Pressure vessel,Gear; | end product: | Tyre oil, carbon black ,wire, waste gas; |

| Warranty of core components: | 3 years; | Place of Origin: | Henan China; |

| Condition: | New; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union; |

| reactor thickness: | 12/14/16/18mm; | reactor life: | 5~8 Years; |

| After-sales Service Provided: | Free spare parts,Field installation, commissioning and training,Field maintenance and repair service,Online support,Video technical support; |

5Tons new installed in UK for waste plastic to oil with distillation recycling

Luoyang Ninca Environmental Technology Co.,Ltd is located in High-Tech Zone, Luoyang City, Henan China. there is a yong group technical department which is maily doing the design for waste engine oil distillation plant to base oil and diesel, Crude oil refinery plant and waste tyre&plastic pyrolysis to low-sulphur diesel . Until now, we have exported 1set of 50Tons waste engine oil distillation to base oil plant to America, 1 set of 50Tons crude oil refinery plant to Myanmar and 1set of new designed 3Tons pyrolysis to diesel plant to UK.

There is another 200Tons waste engine oil plant under manufacturing in China for America client

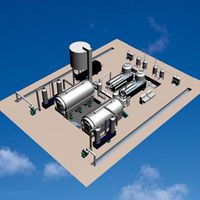

Pyrolysis Layout

| Model | Reactor size | Capacity | Power | area covered |

| RK-PP3 | 2100*2300*16mm | 3Tons | 16.5KW | 12*5 |

| RK-PP5 | 2200*6000*16mm | 5Tons | 18.5KW | 15*10 |

| RK-PP8 | 2600*6000*16mm | 8Tons | 22.5KW | 15*10 |

| RK-PP10 | 2600*6600*16mm | 10Tons | 25.5KW | 20*10 |

| RK-PP12 | 2800*6600*16mm | 12Tons | 30KW | 20*10 |

| RK-PP15 | 2800*7500*18mm | 15Tons | 35.5KW | 25*15 |

The Project Report

Raw Material can be processed:

Waste tyre, Used rubber, Waste plastic (PP,PE,PS, HDPE), Oil sludge,

Fuel as heating material :

Wood, Coal, Carbon briquette, Natural gas, Diesel, Fuel oil, Heavy oil

End product output ( waste tyre as feeding material )

Fuel oil : 40%-45%

carbon black : 30%-35%

waste gas: 3%-5%

wire: 10%-15%

Area Covered:

Machine covered: 300square meters

All including ( office, storage and ect): 600 square meters

Operation workers per shift :

3-4 people

The Income and profit analysis: ( Take 10Tons waste tyre as feeding material )

Income :

| Item | Qty | Cost/Ton | In total |

| waste tyre | 10Tons | 100$ | 1000$ |

| coal | 0.8Tons | 100$ | 80$ |

| electricity | 20KW | 0.2$*16 | 64$ |

| workers | 4 | 30$ | 120$ |

| In Total | 1264$ |

Outcome :

| tyre oil | 0.4%*10 | 600$ | 2400$ |

| Carbon black | 0.35*10 | 50$ | 175$ |

| Wire | 0.15*10 | 100$ | 150$ |

| In Total | 2725$ | ||

| Profit per day | 1461$/day profit |

Main material what the reactor is using :Q345R

Process time ( Take 10Tons as example)

| Feeding time | 40mins by auto-feeder/2-3hours by hand |

| Pyrolysis time | 10-12hours |

| cooling time | 1-2Hours with reactor cover's open |

| discharging time | 40Minns by carbon discharger |

| Manufacturing Time | 10-15days |

| Installation Time | 20-30days |

| Warranty Time | 2Years |

1.

Q: What's The Raw Material Can be processed?

A: Waste Tyre, Used rubber, Waste plastic, OIl sludge, Crude heavy oil

2.

Q:What's the Output after pyrolysis ?

A: Fuel oil , Carbon black, waste gas

3.

Q: What's the daily processing time ?

A: 7-16Hours for pyrolysis time with different processing capacity

4.

Q: Is there any installed machine can be visited ?

A: There are many sets of installed pyrolysis plant in China and there are 2 sets plant nearby our factory. Most welcome to visit

-

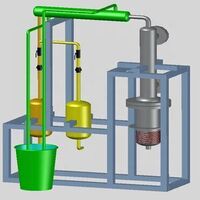

Newly designed waste oil-to-diesel refinery

-

Fully Automatic Plastic Recycling Pyrolysis Diesel Tire Fuel Plant

-

Beston Group does not need to install a small pyrolysis machine for batch pyrolysis of 1-3T/D plastic tire oil sludge

-

Waste Tire Pyrolysis Diesel Plant Machine Manufacturer 5 Ton

-

Automatic control machine for biomass waste plastic tire pyrolysis machine

-

profitable small pyrolysis machine mini pryolysis plant

-

Small batch waste tire/plastic/MSW pyrolysis plant to convert solid waste into fuel oil pyrolysis machine 1-2 tons

-

New Design to Recycle Scrap Tires into Diesel with 50ppm Sulfur

-

Small integrated scrap aluminum and plastic pyrolysis plant provides fuel for machines

-

CE certified 15-50 tons automatic plastic pyrolysis plant continuous waste tire pyrolysis system

Other Products

-

$8000.00 / set

$8000.00 / set