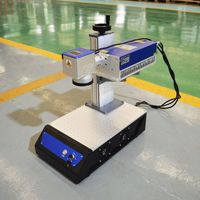

3D fiber laser engraving machine metal mould engraver 50w price

-

Supplier: Jinan Xintian Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Jason Wang -

Price: $8500.00 /set -

Min. Order: 1 set

| Laser Power: | 50w(Optional); | Weight (KG): | 170; |

| Marketing Type: | New Product 2020; | Condition: | New; |

| Weight: | 170kg; | Supply Ability: | 300 Set/Sets per Quarter; |

| After-sales Service Provided: | Engineers available to service machinery overseas,Online support,Video technical support; | Brand Name: | XT LASER; |

| Control System Brand: | EZCAD; | Local Service Location: | Egypt,Saudi Arabia,Australia,Morocco,UAE,Algeria,South Africa; |

| Application: | Laser Marking; | Payment Terms: | L/C,Western Union,T/T; |

| Cooling Mode: | Air Cooling; | Showroom Location: | Egypt,Saudi Arabia,Morocco,South Korea,UAE,Algeria,Australia; |

| Key Selling Points: | Easy to Operate; | Working Accuracy: | 0.01mm; |

| Certification: | ce,ISO; | Place of Origin: | Shandong China; |

| CNC or Not: | yes; | Laser source: | Raycus/IPG; |

| Applicable Industries: | Hotels,Garment Shops,Building Material Shops,Manufacturing Plant,Machinery Repair Shops,Food & Beverage Factory,Farms,Restaurant,Home Use,Retail,Food Shop,Printing Shops,Construction works ,Energy & Mining,Food & Beverage Shops,Advertising Company; | Laser head: | Galvenometer Head; |

| Warranty: | 2 years; | Core Components: | Other; |

| Machinery Test Report: | Not Available; | Video outgoing-inspection: | Not Available; |

| Laser Source Brand: | RAYCUS; | Warranty of core components: | 2 years; |

| Product name: | 3D fiber laser engraving machine metal mould engraver 50w price; | Marking Depth: | 0 ~0.5mm; |

| Control Software: | EZCAD; | Laser Type: | Fiber Laser; |

| After Warranty Service: | Video technical support,Online support; | Laser wavelength: | 1064nm; |

| Graphic Format Supported: | AI,DXF; | Marking Area: | 100*100mm,100mm*100mm; |

| Marking Speed: | 0-7000mm/s; | Packaging Detail: | seaworthy wooden cases; |

50w Jewelry silver gold brass cutting fiber laser marking machine in Middle East

Reliable marking laser for industrial applications

Long service life for minimum maintenance requirement

Laser marking at maximum marking speed

Integration into existing systems and processes

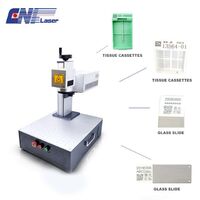

What the materials applied for optical fiber laser marking machine ?

Alloy and metal oxides: Anodized Aluminum

Some non-metallic materials & Special surface treatment:silicon wafer,ceramics,plastic,rubber,epoxy resin,ABS,Printing ink, Plating, Spraying, Coating film.

Rotary Marking Stainless Steel

From paint thickness gauges and microscope dials to sensor bodies and containers, laser marking is fast becoming the standard method in many industries. High quality crisp text and graphics are possible (text down to 0.6mm high) with better durability than ink and paint applied processes

Anodised Aluminium Gauges

Anodised aluminium has excellent product finish and also provides an ideal medium for laser marking. Crisp clear marking with extremely good contrast makes the text and graduations very easy to read. Laser marking allows very fine lines to be produced, like those needed on the vernier scale shown.

Plastic Parts

Many types of plastic can be laser marked which has the advantage of being a permanent mark that cannot wear off, unlike paint and ink applied processes. This is especially important in medical applications (the lower part) where the identification codes need to be permanent and have no toxic effect.

Medical Assembly

All parts of this surgical trocar assembly (steel and plastic) are laser marked with sizes, part numbers, batch codes and the manufacturer's logo. As these are re-usable items that will go through many sterilisation cycles, it is important that the mark is highly resistant to wear.

Clean Surface Plate

This laser cut stainless steel control panel operates in a hostile environment, so the text and graphics must be able to withstand this. This is achieved by laser marking as the surface of the material is permanently changed by the process. This is unlike ink and paint applied processes where the information can be worn or dissolved away.

Dash Board Panels

A relatively cheap option for consoles and panels is to use aluminium. These can be anodised in a wide range of colours and laser marked with text and graphics. This method gives excellent aesthetic results and weighs considerably less than a steel alternative. XTLASER can laser cut the material to shape prior to marking.

installation

After the machine reach the buyer's site,the engineers from the seller are responsible for machine installation and commissioning

Training

The common protection knowledge of laser safety

The basic principle of laser module and the structure of laser cutting machine

The operation skills of fiber laser cutting machine

Equipment operation and the application notice

Skills of equipment daily maintenance,laser module adjustment and spare parts replacement.Training time is about 5 to 10 days.

After-Sales Service

2 years' warranty for the whole machine

2 years' warranty for the fiber laser source

After the warranty period expired,the buyer only need to pay the actual maintenance cost.

XT Laser will pay a return visit all customers for several times one year,and will provide technical support service anytime,and also provide spare parts anytime the buyer want.

After sales service response time: quick response within 8 working hours,after receive the repair call, our after sales engineer will reply as soon as possible.

Brass

Machine Parts

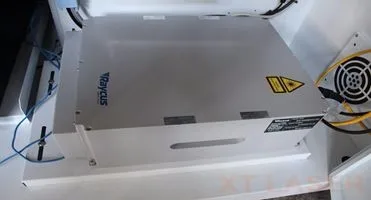

Name: laser source

Brand: Raycus or IPG

Original:China /Germany

Main Features

Name: control cabinet

Brand: XT LASER

Original:China

Machine Parts

Name: 2D worktable

Brand: XTLASER

Original: China

Main Features

Name: lifting pillar

Brand: XT LASER

Original: China

YouTube video

2.mobile phone shell laser marking https://youtu.be/AIKSgDjVGs4

3.QR code marking https://youtu.be/meuPiYoQ-kI

4.auto parts laser marking https://youtu.be/a2TY-892thI

5.Automatic System for LED bulb laser marking machine https://youtu.be/1KcvNDx8L68

What are the primary products of your company?

Our primary products include laser marking machine, laser engraving machine, laser cutting machine, and laser welding machine.

Where is your laser equipment applied to?

Our laser equipment is applied to metal, non-metal, textiles, leather, shoes, advertisement, gifts, electronic components, stamp, etc

Which countries are your laser machinery sold to?

Our products are widely exported to Poland, Russia, Ukraine, Korea, Thailand, Egypt, Brazil, Australia, Singapore, Saudi Arabia, Turkey, India, Italy, and other countries.

How long is the delivery time?

The products will be delivered to you within one week after the order is confirmed.

What certificate has your company got?

All of our product with CE, ISO, BV.

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

-

Mobile App to operate Mr Carve C2S 20W Fiber Laser Engraving Machine Auto Focus Laser Engraving Machine Laser Marking Machine for All Metals

-

Fiber Laser Marking Machine Small Industrial Handheld Metal Coding Machine Portable Metal Engraving Machine

-

Portable DAJA C1 80*80mm Laser Engraving Machine Laser Marking Machines Laser Machine Printer for Leather Wood Plastic Bamboo

-

UV Laser Printing 5w 10w 3w Mini Portable Jewelry Jpt Metal Plastic UV Laser Marking Machine

-

2D 50W Raycus Mini Fiber Laser Cutting Machine for Jewelry Brass Cutting

-

Top manufacturer 20w 30w portable fiber laser engraving machine for metal plastic marking

-

Fiber laser 50w logo printer for glass cup stainless steel coffee cup bottle engraving machine

-

20W 30W 50w 60W 100W Fiber Laser Marking Machine Laser Marking Machine Raycus MAX JPT MOPA Source Best Price

-

355nm 30kw 50kw Beverage Bottle Time Marking Logo Manufacturer Mark Perfume Uv Laser Marking Machine For Plastic Glass Medical Slides

-

Portable machine for laser marking of split table 20w 30w 50w mini laser marking with fiber

Other Products

-

$20000.00 / set

$20000.00 / set