Fangyuan automatic expandable polystyrene styrofoam box making eps machine with vacuum

-

Supplier: Hangzhou Fangyuan Plastics Machinery Co., Ltd. -

Region: Zhejiang, China -

Contact: Ms ying huang -

Price: $42000.00 /set -

Min. Order: 1 set

| Package Preview: | ; | Marketing Type: | Hot Product 2019; |

| Brand Name: | Fangyuan; | After Warranty Service: | Field maintenance and repair service; |

| Application: | fish box,packaging; | Packaging Detail: | wooden. HS:84778000. styrofoam machine; |

| Condition: | New; | Processing Type: | Foaming Machine,Foaming Machine; |

| Port: | Shanghai/ningbo; | Key Selling Points: | Energy saving; |

| Machine Type: | SPZ100-200T,EPS Foam Shape Molding Machine; | Place of Origin: | Zhejiang China; |

| Payment Terms: | L/C,T/T; | Warranty of core components: | 1 Year; |

| Video outgoing-inspection: | Provided; | Core Components: | Motor,Pump,PLC; |

| Machinery Test Report: | Provided; | Local Service Location: | Egypt,Brazil,India,Mexico; |

| Weight (KG): | 10000; | Certification: | ce,ISO9001:2015; |

| Applicable Industries: | Packaging; | Dimension(L*W*H): | 5220*3760*5120mm; |

| Warranty: | 1 year; | Showroom Location: | Egypt,Turkey,Viet Nam,Saudi Arabia,Indonesia,India,Thailand,Algeria,None; |

| After-sales Service Provided: | Engineers available to service machinery overseas; | Name: | eps machine; |

| Voltage: | 380V; | Supply Ability: | 2000 Set/Sets per Year; |

| Performance: | high-efficiency eps machine; | Steam consumption: | (8-10)steam of 1Tmaterial; |

| Power (kW): | 11-20.7kW; | HS: | 84778000; |

| Mould Dimension: | 1000*800; | Product Type: | eps machine,EPS Foam; |

SPZ100-200T eps machine advantages

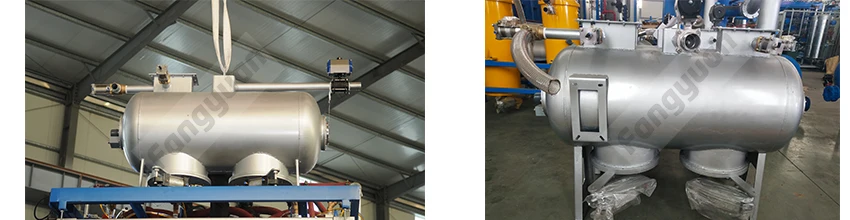

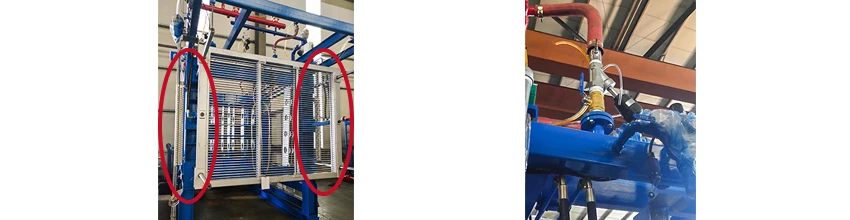

1.The eps machine is treated with cold zinc spraying after the manufacturing works which improves service life.

2.The Styrofoam making machine adopt new split structure and wear-resistant guide bush (500# high strength brass with graphite). It`s bearing can be changed conveniently and keep the guide difficult to wear.

3.The eps machine adopts horizontal barrel which volume is 330l. With double rotation chamber discharge and has 44 filling outlets. Each rotation table has 22 filling outlets. If the customer has special requirement, can add to 48 or 64 filling outlets.

4. The air exhaust has been upgraded and installed on both sides, with 1.5’’ feed valve which will better for feeding the material.

5. The drain pipe on the movable side adopts flexible pipe.

6. All frames are welded on steel plate, this greatly improves machine strength and service life. This eps machine adopts hydraulic cylinder de-mould ejector device.

7. This eps machine adopts electronic contact pressure gauge and balance valve to control the steam pressure.

8. With high support pipeline.

9.With 1.2m high machine leg and H type frame which will increase stability. The drain pipe is installed on the machine leg, it will easy to drainage.

|

Item |

Unit |

SPZ100T |

SPZ120T |

SPZ140T |

SPZ160T |

SPZ175T |

SPZ180T |

|

Mould Dimension |

mm |

1000×800 |

1200×1000 |

1400×1200 |

1600×1350 |

1750×1500 |

1800×1600 |

|

Max Product Dimension |

mm |

800×700×330 |

1000×900×330 |

1200×1000×330 |

1400×1100×330 |

1550×1300×330 |

1610×1400×330 |

|

Outside Dimensions |

mm |

4760×1900 ×4700 |

4760×2100 ×4900 |

4920×2250 ×4660 |

5220×2530 ×4690 |

5220×2680 ×4790 |

5220×2760 ×5120 |

|

Weight |

t |

4.50 |

5.20 |

5.70 |

7.00 |

7.50 |

8.00 |

|

Cycle Time |

s |

60-90 |

60-100 |

60-150 |

90-160 |

90-160 |

120-190 |

-

High Pressure Polyurethane Foam Injection Machine Polyurea Spraying Machine

-

High Viscosity Pneumatic Oil Pump Grease Barrel Pump Air Barrel Pump

-

Outdoor party event hot sale snow foam daddy super re maquina de espuma foam machine

-

Q2600 Polyurethane Foam Sprayer

-

Portable Polyurethane Sprayer Foaming Machine

-

Automatic Control EPS Foam Vertical Cutting Machine

-

Closed cell polyurethane foam insulation machine FD-E10H

-

Closed cell polyurethane thermal foam insulation machine spraying machine pu foam spraying machine

-

Sponge cutter for kitchen cleaning

-

MDI Rigid Polyol Isocyanate Polyurethane Foam Insulation Spray From China Factory!

Other Products

-

$40000.00 / set

$40000.00 / set -

$20000.00 / set

$20000.00 / set -

$8800.00 / set

$8800.00 / set -

$57000.00 / set

$57000.00 / set