Xhnotion Portable Vortex Tube Cold Air Gun for Dry Machine and Precise Spot Cooling XR-L40

-

Supplier: Ningbo Xhnotion Pneumatic Technology Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Mac Chang -

Price: $165.00 /piece -

Min. Order: 1 piece

| Marketing Type: | Ordinary Product; | Product Name: | Vortex Tube Cold Air Gun; |

| Type: | Cooler; | Local Service Location: | None; |

| Video outgoing-inspection: | Not Available; | Inlet Switch Port: | 1/4"BSPT; |

| Certification: | ce; | Warranty: | 1 Year; |

| Machinery Test Report: | Not Available; | Place of Origin: | Zhejiang China; |

| Selling Units: | Single item; | Decibel: | 52-57dBA; |

| Cooling Capacity: | 1000-2800Btu/hr; | Supply: | Compressed Air; |

| Brand Name: | XHnotion; | After Warranty Service: | Spare parts; |

| Magnetic Base Size: | DN80; | Warranty of core components: | 1 Year; |

| Packaging Detail: | Transparent Pastic Bag + White Small Box + Neutral Carton + Pallet Custom packaging are available, XHnotion brand packaging are available; | Applicable Industries: | Construction works ; |

| Single gross weight: | 1.0 KG; | Single package size: | 30X16X16 cm; |

| Standard: | ISO9001:2008; | Showroom Location: | None; |

| Core Components: | Engine; | Package Preview: | ; |

| After-sales Service Provided: | Online support; | Muffler Port: | 3/8"BSPT; |

Portable Vortex Tube Cold Air Gun for Dry Machine and Precise Spot Cooling

What is Cold Air Gun?

Cold Air Gun use vortex tube technology and filtered compressed air to produce sub-freezing air as low as -30ºF for numerous industrial spot cooling applications.

With no moving parts to wear out, Cold-Air Guns require no electricity at the target, just a compressed air source.

Cold Air Guns are most often used for cooling of metal parts, in the machining and repair of metals, plastics, wood, ceramics and other materials.

Cold air machining outperforms mist coolants and substantially increases tool life and feed rates on dry machining operations.

The effective air cooling from a Cold Air Gun can eliminate heat-related parts growth while improving parts tolerance and surface finish quality.

Air Gun Nozzles have adjustable temperature and flow settings, and some models have a frost free nozzle to eliminate mess from frost and condensation.

How does Cold Air Gun Work

By Vortex Tube, compressed air into two low pressure streams, one hot and one cold. The hot airstream is muffled and discharged through the hot air exhaust. The cold air is muffled and discharged through the flexible hose, which directs it to the point of use. The magnetic base provides easy mounting and portability.

Specification

| Product Name | Cold Air Gun | ||

| Supply | Compressed Air | ||

| Air Pressure | 4-9Bar | ||

| Kits | Magnetic Base, Ball Valve, Push-in Fitting, Coolant Tube | ||

| Magnetic Base Size | DN80 | ||

| Inlet Switch Port | 1/4"BSPT | ||

| Muffler Port | 3/8"BSPT |

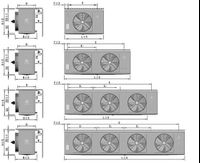

Model List

| Model | Air Pressure (Bar) |

Air Consumption (m³/min) |

Cooling Capacity (Btu/hr) |

Decibel (dBA) |

| XR-L15 | 6.9 | 0.425 | 1000 | 52 |

| XR-L25 | 6.9 | 0.700 | 1700 | 53 |

| XR-L30 | 6.9 | 0.853 | 2000 | 55 |

| XR-L40 | 6.9 | 1.130 | 2800 | 57 |

2. Coolant tubing is connected to cold air outlet.

3. Compressed air supply is connected to the inlet with a pressure of 4-9 Bar.

4. Use ball valve to control on and off of air supply.

5. Firstly, unscrew 1/8"BSPT seal screw on the end of gun, and then use a slot screwdriver to rotate the position with clockwise to increase cooling capacity, and vice versa.

Note: Don't screw too tight ! Otherwise, it cannot achieve cooling effect.

Applications

1. Widely used in milling, drilling, turning and other metalworking operations

2. Machining of plastics, composites, wood and other materials

3. Surface grinding, drill and tool sharpening

4. CNC routers, blades and band saws

5. Spot cooling of parts, molds and assemblies

6. Industrial sewing and textiles

7. Setting hot melts and adhesives

Troubleshooting & Maintenance

If Cold Air Gun dose not perform properly, check for these common problems:

1. Inlet Pressure.

Low inlet pressure supply will cause poor performance.

(standard pressure of the cooling gun is 6.9 Bar)

Usually compressed air does not use only one tool or device, so the pressure and flow rate of the terminal will be reduced.

2. The inner diameter of the compressed air pipe is not large enough, resulting in low pressure supply.

3. The internal diameters of various fittings of compressed air are smaller than the internal diameter of the pipes, so the pressure will lost in many places and the flow rate will be reduced.

4. Pipes or fittings are leaky

5. Inlet Temperature.

A Cold Gun provides a temperature drop from supply air temperature. In some cases, the supply air is warmer than ambient air due to compressed air lines running across ceilings, near furnaces, direct sun, etc. In this case, the cold air may be warmer than anticipated and adequate refrigeration may not be available for the application.

6. Back Pressure.

The performance of a Cold Gun deteriorates with back pressure on the cold end exhaust. Use only the flexible segmented hose included with the Cold Gun System.

7. No Cold Flow.

If the filter is not drained regularly, water may overflow into the Cold Gun and cause internal freezing. This can reduce or even stop cold air flow. Drain the filter often, or crack open for a small continuous air bleed. If internal freezing occurs, any one of the following will correct the problem:

Solutions

1.Please increase the supply of compressed air.

2.For the compressed air input hose, please use 10-12 mm. If you use a suitable fittings, it will increase the flow of compressed air.

3.Please check whether the pipe system is leaking.

4.Blow air (use an air gun) into the cold muffler with the Cold Gun off.

5. Turn the Cold Gun off for a few minutes.

6. Put a dryer on the compressed air supply.

Note: The high temperature of the hot air end is normal, but please take care to prevent accidents.

When the hot air has not been discharged, part of the heat has been transferred to the vortex tube, so the temperature is not high after being discharged from the gun body, and it does not harm to the human body.

How to repair and clean Cold Air Gun

The Cold Gun has no moving parts. Maintenance is not normally required provided the air filter is used properly. However, if internal cleaning should be necessary, the following procedure is recommended:

1. Unscrew the flexible segmented hose. Remove the cold muffler, turning counter clockwise. Pin wrench holes are provided for this purpose.

2. Remove the "O"-ring, generator (white plastic part), hot end fitting and magnetic base. Inspect for dirt and clean as necessary.

3. Immerse all parts (except cold muffler) in mild cleaning or degreasing solution. Use an air gun to remove solution and contaminates.

4. Re-install generator, "O"-ring, cold muffler, magnetic base and hot end fitting.

Related Product

XHnotion Pneumatic Components

Packing & Shipping

Packing:

Transparent Pastic Bag + White Small Box + Neutral Carton + Pallet

Custom packaging are available, XHnotion brand packaging are available

Shipping:

Ways: Sea, Air, Courier

Export port: Ningbo or Shanghai, China

Delivery time: 3 days to 30 days depends on actual orders.

Express: TNT, UPS, DHL, FedEx, SF Express.

Our Company

XHnotion originate from notion between pneumatic power and human.

(X stands for winds, H stands for human)

In Chinese, XHnotion stands for 'we do, we promise' we read it 'X-notion'.

The company XHnotion Pneumatic was founded in 2007 and has developed with a steadily growing success to a reliable partner for international established clients.

This success of the company XHnotion Pneumatic is based on:

High class quality standard

Customer satisfaction

Fair price policy

Flexibility

The high-class quality standard of the products of company XHnotion is reflected in our quality management system, certificated ISO 9001:2008. And we got CE, RoHS, REACH certificate for international market.

XHnotion Pneumatic manufactures below products:

Pneumatic Components: Air Cylinder, Solenoid Valve, FRL.

Solenoid Valve: Standard Solenoid Valve, Multipurpose Solenoid Valve, Pneumatic Angle Valve.

Pneumatic Fittings: Plastic Pneumatic Fittings, Metal Pneumatic Fittings, Pneumatic Muffler, Water Push in Fittings.

Air Gun & Couplers: Pneumatic Couplings, Air Guns, Air Tool Kits.

Air Hoses: Air Tubing, PTFE Tubes, Tube Cutter, Pipes.

Trade Shows

Our Service

1. We offer one stop solution. Over 5000 items for you to save efforts and costs.

2. We have molds workshop, die-casting workshop, CNC workshop, plastic injection workshop to

make sure each part exactly as the drawing and good function.

3. We will reply you within 24 hours.

4. Whatever quantity you are requesting, we always offer you the best quality.

5. 3D drawing, CAD drawing service for custom fittings, hose, valve, cylinder.

FAQ

Payment Terms :

We accept T/T, L/C, Paypal, Western Union,etc.

Samples Policy :

For regular item, samples against your courier account or you pick up from us.

For custom items, we will discuss by email.

Return Policy:

We assure you 1 year policy after shipment.

If there is any problem during this period, please contact us for support.

-

New copeland rotary compressor ZB88KQ-TFD-550 emerson compressor

-

Professional Supplier Cold Storage Evaporator Air Cooler Air Cooling Unit Walk In Cooler Evaporator

-

Newst refrigerator trailer refrigeration unit with freezer for thermo king

-

Showcase Small Refrigeration Condenser Compressor Condensing unit 3/4HP

-

WLD-L520 Semi-automatic air conditioner refrigerant recovery charging machine

-

AC 220-240V Single Phase Power Supply Small Mobile Refrigerator Truck Body Trailer Cooler Complete Mobile Cold Room

-

Cold storage air-cooled condenser Low-noise unit cooler for cold storage evaporator

-

HVAC Refrigerant Charge Recovery Station with 5 Valve Manifold Gauge for Car Air Conditioner Repair

-

Refrigeration equipment, refrigeration condensing units

-

High Quality Good Price Factory Suppler Air Cooled Condensing Unit Bitzer Condensing Unit