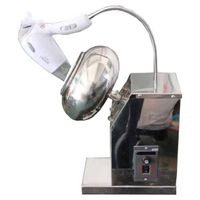

Pill Coating Machine

-

Supplier: Rotech Bioengineering Co., Ltd. -

Region: Shanghai, China -

Price: $20000.00 /unit -

Min. Order: 1 unit

| After-sales Service Provided: | Free spare parts,Field maintenance and repair service,Video technical support,Online support; | Warranty: | 1 Year; |

| After Warranty Service: | Video technical support,Online support,Spare parts,Field maintenance and repair service; | Place of Origin: | Shanghai China; |

| Coating Temperature (℃): | 80 - 130 ℃; | Condition: | New; |

| Applicable Industries: | Manufacturing Plant,Food & Beverage Factory; | Payment Terms: | L/C,Western Union,T/T; |

| Core Components: | PLC,Engine,Bearing,Gearbox,Motor,Pressure vessel,Gear,Pump; | Marketing Type: | New Product 2020; |

| Coating Drum Diameter (mm): | 1580; | Package Preview: | ; |

| Key Selling Points: | High Productivity; | Dimension(L*W*H): | 2000*2277*2660; |

| Showroom Location: | Philippines,Brazil,Pakistan,Mexico,Russia,Algeria,Bangladesh; | Rotating speed of coating pan(RPM): | 1-25; |

| Local Service Location: | Turkey,Viet Nam,Philippines,Brazil,Pakistan,Mexico,Russia,Thailand,South Africa; | Brand Name: | Rotech; |

| Coating Type: | Heating & Coating; | Supply Ability: | 20 Unit/Units per Year; |

| Motor of air exhaust cabinet(Kw): | 0.75; | Voltage: | 380V 50hz three phase; |

| Video outgoing-inspection: | Provided; | Port: | Shanghai port; |

| Packaging Detail: | International Export Wooden Case Packing, Water Proof Land and seaworthy packing of the goods shall be packed. The innermost will be packed by plastic, interior anti-shake foam and the outermost wood board. Before the shipment, the detailed packing list shall be sent out to customer.; | Power of main machine (Kw): | 0.55; |

| Usage: | Food, MEDICAL, Chemical, Tablets,pills,sugar.etc; | Load capacity (L): | 10L; |

| Certification: | CE,ISO9001; | Diameter of coating pan(mm): | 500; |

| Warranty of core components: | 1 Year; | Machinery Test Report: | Provided; |

BG Automatic tablet film coating machine

The BG coating machine is ideal for organic, water-soluble film and sugar coating of tablets, pills and sweets in the pharmaceutical and food stuff industries.

Scope of application

This machine is widely used in the fields of pharmacy, food, biological products, etc. It can package various organic films, water-soluble films and sugar coatings for various tablets, pills, candies, etc. (in terms of drugs, it can achieve slow and controlled release effects). The whole machine has the advantages of beautiful appearance, high efficiency, low energy consumption and small occupation.

The coating process has no dust scattering and no slurry splashing, which improves the working environment and reduces cross-contamination of tablets; the tablet coating process is simple, which greatly shortens the coating time and improves production efficiency.

Basic working principle:

The tablet core is in the clean and airtight rotating drum of the coating machine, constantly making complex trajectories, turning smoothly, and frequently exchanges. The coating medium stirred by the constant temperature mixing barrel is sprayed from the spray gun to the tablet core through the action of the peristaltic pump. At the same time, under the action of hot air and negative pressure, the 100,000-grade clean hot air supplied by the hot air cabinet passes through the tablet core, passes through the bottom sieve, and is discharged from the air door, so that the coating medium is quickly dried on the surface of the tablet core to form a firm and dense , Smooth surface film, the whole process is automatically completed under PLC control.

Technical parameters

|

Model |

BG600E |

BG400E |

BG150E |

BG80E |

BG40E |

BG10E |

BG20H |

BG5H |

|||||||

|

Load capacity (L) |

600L |

400L |

150L |

80L |

40L |

10L |

20L |

5L |

|||||||

|

Rotating speed of coating pan(RPM) |

1-12 |

1-13 |

1-16 |

1-19 |

1-21 |

1-25 |

1-25 |

1-30 |

|||||||

|

Power of main machine (Kw) |

5.5 |

3 |

2.2 |

1.5 |

1.1 |

0.55 |

0.75 |

0.37 |

|||||||

|

Diameter of coating pan(mm) |

1580 |

1580 |

1200 |

930 |

750 |

500 |

680 |

480 |

|||||||

|

Motor of air exhaust cabinet(Kw) |

11 |

7.5 |

5.5 |

3 |

2.2 |

0.75 |

2.2 |

1.1 |

|||||||

|

Air exhaust flow(m3/h) |

15450 |

10000 |

7419 |

5268 |

3517 |

1285 |

3517 |

2500 |

|||||||

|

Motor power of hot air cabinet(Kw) |

5.5 |

3 |

1.5 |

1.1 |

0.75 |

0.37 |

0.75 |

0.25 |

|||||||

|

Hot air flow(m3/h) |

7419 |

5200 |

2356 |

1685 |

1285 |

816 |

1200 |

504 |

|||||||

|

Weight of main machine (Kg) |

2800 |

1562 |

1020 |

684 |

500 |

200 |

625 |

750 |

|||||||

|

Clean air pressure (Mpa) |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

0.4 |

|||||||

|

Clean air consumption (m3/min) |

2 |

1.5 |

1 |

0.4 |

0.4 |

0.3 |

0.6 |

0.6 |

|||||||

|

Main machine (mm) |

2000*2277* 2660 |

2000*1670* 2660 |

1570*1260* 2250 |

1210*1000* 1900 |

1000*800* 1900 |

900*620* 1800 |

1050* 960* 1800 |

1250* 900* 1700 |

|||||||

|

Hot air cabinet(mm) |

1600*1100* 2350 |

1000*900* 2300 |

900*800* 2050 |

900*800* 2050 |

900*800* 2050 |

800*650* 1600 |

|||||||||

|

Air exhaust cabinet (mm) |

1050*1000* 2470 |

1050*1050* 2300 |

950*950* 2245 |

900*820* 2130 |

820*720* 1750 |

650*600* 1000 |

-

BYC-600 sugar coating machine is used for sugar coating of tablets and pills in the food industry

-

Nut/Chocolate/Almond Peanut Candy Coating Pan Machine Nut Icing Machine

-

Hot Sale Stainless Steel Small Pill Candy Sugar Diaphragm Coating Machine

-

BYC 800 sugar coating machine, tablet and pill coating machine, sugar coating machine

-

Commercial Fondant Sugar Coating Machine Almond Nut Peanut Solution Coating Machine

-

Hot Sale All Stainless Steel Tablet Film Coating Equipment Sugar Coating Machine

-

Laboratory Tablet Coating Machine Pharmaceutical Equipment

-

Food Small Automatic Nut Candy Candy Chocolate Peanut Almond Candy Tablets Nano Film Coating Pot Machine Coating Machine

-

Polishing machine Peanut tablet coating machine

-

Small candy nut icing pan machine