DC RF microwave circuits aluminum nitride ceramic sheet substrate chip

-

Supplier: Shenzhen Hard Precision Ceramic Co., Ltd. -

Region: Guangdong, China -

Contact: Ms Alice Tang -

Price: $0.10 /piece -

Min. Order: 1 piece

| Dimension: | Customized; | Type: | Dielectric Ceramics; |

| Feature: | high strength, high temperature, wear resistance; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,PayPal; |

| Place of Origin: | China; | Color: | Natural; |

| Density: | 3.2g/cm3; | Maximum Teperature: | ≥2000C; |

| Port: | FCA Shenzhen; | Model Number: | AIN 007; |

| Brand Name: | Hard; | Material: | Aluminum Nitride Ceramic,Aluminum Nitride; |

| Package Preview: | ; | Thermal Expansivity: | 3.2*10-6℃; |

| Supply Ability: | 1000000 Piece/Pieces per Month; | Packaging Detail: | Box/Carton / Plastic bag / Wooden case... (Customized); |

| Thermal Conductivity: | 170-186W/mK; | Shape: | Customized; |

| Application: | chemical, electric power, metallurgy, petroleum, electronic appliances; |

DC RF microwave circuits aluminum nitride ceramic sheet substrate chip

Reputation depends on quality, quality comes from Hard!

Aluminum Nitride Ceramics:

Aluminium Nitride Ceramic is a ceramic in which aluminum nitride (AIN) is the main phase. Chemical composition AI 65.81%, N 34.19%, specific gravity 3.261g/cm3, white or off-white, single crystal colorless and transparent, sublimation decomposition temperature under normal pressure is 2450 °C. It is a high temperature heat resistant material. Thermal expansion coefficient (4.0-6.0) X10-6/°C. Polycrystalline AIN has a thermal conductivity of 260 W/(m.k), which is 5-8 times higher than alumina, so it has good thermal shock resistance and can withstand extreme heat of 2200 °C. In addition, aluminum nitride is not attacked by aluminum liquid and other molten metals and gallium arsenide, and particularly has excellent corrosion resistance to molten aluminum liquid.

Data Sheet

Properties of Aluminum Nitride Ceramics |

||

| Item | Unit | ypical Values |

| Physical Properties | ||

| Color | White Grey | |

| Density | g/cm3 | 3.3-3.4 |

| Chemical Formula | / | AIN |

| Gas permeability | 0 | |

| Water Absorption | 0 | |

| Mechanical Properties | ||

| Moh's Hardness | 5 | |

| Vickers hardness | Gpa | 11 |

| Fracture Toughness KIC | MPa•m1/2 | 2.6 |

| Flexural Strength | Mpa | 466-496 |

| Compressive Strength | Mpa(lb/in2x103) | 2100 |

| Modulus of Elasticity(25°C) | Gpa | 320 |

| Thermal Properties | ||

| Thermal Conductivity | W/m·K | 170-186 |

| Thermal Expansion Coefficient | 10-6/ºC | 3.2-3.4 |

| Thermal Shock Resistance | T (ºC) | 400 |

| Specific Heat(25°C) | J/kg.K | 720 |

| Maximum Use Temperature | °C | 2000 |

| Electronic Properties | ||

| Dielectric Strength | KV/mm | 17-19 |

| Dielectric Constant | Er | 8.8 |

| Dielectric Loss Angle | 1 MHz (×10-3) | 0.3 |

| Volume Resistivity(400~600ºC) | Ω.cm | 2.75*1014 |

Ø (1) high thermal conductivity (about 320W / m · K), close to BeO and SiC, more than 5 times that of Al2O3;

Ø(2) The thermal expansion coefficient (4.5×10-6°C) is matched with Si (3.5-4×10-6°C) and GaAs (6×10-6°C);

Ø (3) excellent electrical properties (dielectric constant, dielectric loss, volume resistivity, dielectric strength);

Ø(4) good mechanical properties, higher flexural strength than Al2O3 and BeO ceramics, can be sintered at normal pressure;

Ø (5) good optical transmission characteristics;

Ø(6) non-toxic;

Application

1. Aluminum nitride powder has high purity, small particle size and high activity, and is the main raw material for manufacturing high thermal conductivity aluminum nitride ceramic substrate.

2, aluminum nitride ceramic substrate, high thermal conductivity, low expansion coefficient, high strength, high temperature resistance, chemical corrosion resistance, high resistivity, small dielectric loss, is an ideal large-scale integrated circuit heat sink substrate and packaging materials.

3. Aluminum nitride has high hardness and exceeds traditional alumina. It is a new type of wear-resistant ceramic material, but it can only be used for severely worn parts due to its high cost.

4. Using AIN ceramics for heat resistance, melt erosion and thermal shock resistance, GaAs crystal crucible, Al evaporating dish, magnetic fluid power generation device and high temperature turbine corrosion resistant parts can be fabricated, and its optical properties can be used as an infrared window. The aluminum nitride film can be made into a high frequency piezoelectric element, a very large scale integrated circuit substrate, or the like.

5, aluminum nitride heat-resistant, resistant to molten metal erosion, stable to acid, but easy to be eroded in alkaline solution. The AIN fresh surface is exposed to moist air and reacts to form a very thin oxide film. By utilizing this property, it can be used as a crucible and a die-casting mold material for smelting metals such as aluminum, copper, silver, and lead. AIN ceramics have good metallization properties and can be widely used in the electronics industry as an alternative to toxic cerium oxide.

Aluminum nitride ceramic ceramics are used in ceramic integrated heat-dissipating materials, such as hybrid integrated circuits, sensors, chip capacitors, chip sensors, laser carriers, power dividers, interdigital capacitors and spiral inductors, and aluminum nitride ceramic sheets. With high thermal conductivity and high temperature resistance, good electrical insulation and chemical stability, low dielectric constant and thermal expansion coefficient, it is an ideal packaging material and heat dissipation material for large-scale integrated circuits, semiconductor module circuits and high-power devices. , circuit components and interconnect carriers.

Shenzhen Hard Precision Ceramic CO.,Ltd founded in 2007, located in Shenzhen of China. We are a company that integrates development, design, moulding, sintering, production and sales of precision ceramic parts. After 12 years of development, we have cooperated with more than 3000 companies and 60 universities at domestic and abroad; our factory covers an area of 2000 square meters, 50 employees, and annual production value of nearly 20 million. We have a higher visibility and better reputation in the same industry.

Compared with metals material, ceramic materials have excellent properties such as high hardness, high strength, high temperature(fire) resistance, wear resistance, corrosion resistance, acid and alkali resistance, oxidation resistance, insulation, nonmagnetic, good chemical stability and other excellent performance, so it is often used in the environment of the metal material is not up to. Advanced ceramics application prospect are very widely. It’s widely used in aerospace, aviation, military industry, nuclear power, machinery, textile, chemical, electronic, food, medical, etc. We provide alumina ceramic, zirconia ceramic, silicon nitride (Si3N4) ceramic, macor (mica glass ) ceramic, aluminum nitride (AIN) ceramic, silicon carbide (SiC) ceramic, boron nitride (BN) ceramic, quartz ceramic, mullite ceramic, cordierite ceramic etc.

Our products include ceramic rods, ceramic tubes, ceramic pipes, ceramic plates, ceramic sheets, ceramic blocks, ceramic nozzles, ceramic plungers, ceramic washers, ceramic spacers, ceramic substrates and precision parts for industrial. We have all-line high precision equipments from ceramic forming, sintering to precision machining. We are looking forward a sincere cooperation with customers all over the world.

Why Choose Us?

1.12 years of professional production industrial ceramics factory

2.High quality products with low price

3.High precision parts with lowest tolerance

4.Short time for production

5.Has a group of experienced, professional and efficient R&D team

6.Has a good reputation in China and abroad.

7.MOQ is not limited, small quantity is welcome.

8.Vigorous team and good after-sales service

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shippment.

-

High purity C799 alumina ceramic protection tube for thermocouple 99 Al2o3

-

ANSI high voltage pin type suspension porcelain insulator

-

High-purity 99.8% alumina ceramic protective tile

-

High quality and lowest price glazed porcelain bobbin insulator ansi 53-1

-

Piezoelectric ceramic ultrasonic microporous nebulizer, working time more than 5k hours

-

18mm 36KHZ piezoelectric ceramic element

-

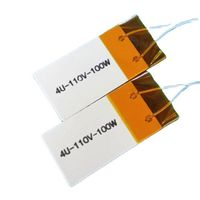

110v 220v ultrasonic cleaner heater aluminum MCH ceramic heating element OEM

-

Heater

-

Diameter 12MM 15MM Piezo Ceramic Brass Disc Alarm Sound Piezo Ceramic Plate Buzzer with 60MM Wire

-

Ceramic Manufacturer Repair Parts Piezoelectric Ignition Piezoelectric Spark Ignition Switch