High speed open-center rotating hydraulic operated lathe chuck rotary cylinder

-

Supplier: Changzhou Drake International Trade Co., Ltd. -

Region: Jiangsu, China -

Contact: Ms Joanna Zhou -

Price: $37.62 /set -

Min. Order: 1 set

| Package Preview: | ; | Core Components: | MOTOR; |

| Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram,Paypal; | Power: | HYDRAULIC; |

| Structure: | Rotary Cylinder; | Pull side of oil thru-hole cylinder: | 67.5 (hydraulic through-hole cylinders); |

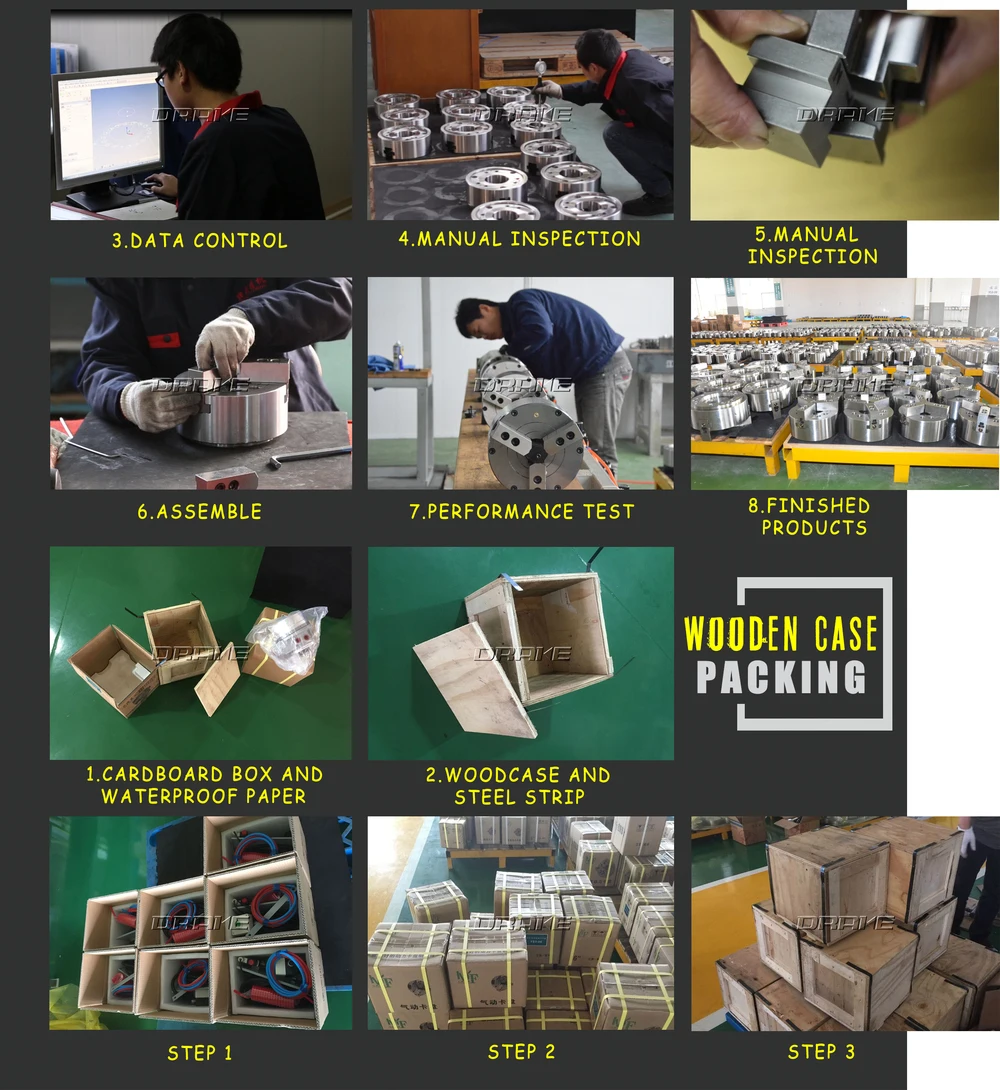

| Packaging Detail: | 1.The inner is polyethylene of hydraulic cylinder 2.The outside is packed in a paper case hydraulic cylinder 3.Wooden case hydraulic cylinder; | Machinery Test Report: | Provided; |

| Applicable Industries: | lathe machine; | Local Service Location: | none; |

| Port: | SHANGHAI, NINGBO, TIANJIN,QINDAO,DALIAN, GUANGZHOU; | Showroom Location: | none; |

| Place of Origin: | Jiangsu China; | Supply Ability: | 12042 Set/Sets per Month High speed rotating hollow oil hydraulic cylinder for aluminum p; |

| Warranty of core components: | 1 YEAR; | Body Material: | aluminum; |

| Brand Name: | IVY hydaulic chuck oil cylinders; | Material of Oil Cylinders: | Aluminum Alloy (oil cylinders); |

| Max. working pressure of cylinder: | 4.0 kgf (hydraulic chucks cylinder); | Iten of oil hydraulic chuck: | rotating hydraulic operated lathe chuck oil cylinder; |

| After Warranty Service: | Online support; | Hightest turnover number of cylinder: | 8000 min-1 rpm (oil cylinders); |

| Press side of hydraulic cylinder: | 69.8 (hydraulic power cylinder); | Standard or Nonstandard: | Standard; |

| Moment of inertia for cylinder: | 0.05 kg.m2 (hydraulic lathes cylinders); | Warranty: | 1 YEAR; |

| Video outgoing-inspection: | Provided; | Marketing Type: | Hot Product 2019; |

| Condition: | New; | Stroke of hydraulic cylinderds: | 15mm (oil hydraulic lathe cylinders); |

High speed open-center rotating hydraulic operated lathe chuck oil cylinder

Technical features:

1. High speed.

2. Compact & Lightweight.

3. Thru-hole Capacity.

4. Built-in Safety Check Valves which prevents the internal pressure from sudden

declining so that the workpiece will not fly out and cause a serious accident.

5. Easy for Heat Dissapation.

There are three questions to answer to aid the correct choice of power chuck:

1. Type and model of CNC lathe.

2. Length of workpiece?

3. Outer diameter of workpiece?

4. Processing requirement?

Size Parameters

| Model/Spec |

A I.D |

B | C | D |

E (h7) |

F |

G1 (max.) |

G1 (min.) |

G2 (max.) |

G2 (min.) |

H | J | K | L | M1 | M2 | N1 | N2 |

| TH428 | 90 | 130 | 120 | 100 | 80 | 40 | 10 | - | 35 | - | 45 | 127.5 | 155 | 6-M8×15 | M33×1.5 | 25 | M34×1.5 | 26 |

| TH536 | 105 | 150 | 135 | 115 | 100 | 50 | 15 | - | 40 | - | 47.5 | 125.5 | 170.5 | 6-M10×20 | M42×1.5 | 25 | M44×1.5 | 28 |

| TH646 | 125 | 169 | 156 | 130 | 100 | 65 | 15 | - | 40 | - | 60 | 135.5 | 193.5 | 12-M10×20 | M55×2 | 30 | M52×1.5 | 32 |

| TH852 | 150 | 198 | 188 | 170 | 130 | 70 | 20 | 0 | 45 | 25 | 66 | 145 | 198 | 12-M10×20 | M60×2 | 30 | M58×1.5 | 34 |

| TH1075 | 175 | 225 | 213 | 190 | 160 | 95 | 25 | - | 50 | - | 62 | 166.5 | 231 | 12-M10×22 | M85×2 | 35 | M84×2 | 40 |

| TH1291 | 205 | 255 | 240 | 215 | 180 | 110 | 30 | - | 55 | - | 64.5 | 180.5 | 250 | 12-M12×24 | M100×2 | 35 | M99×2 | 46 |

| TH1512 | 250 | 315 | 305 | 275 | 230 | 140 | 30 | - | 55 | - | 68 | 193 | 273 | 12-M16×32 | M130×2 | 45 | M134×2 | 46 |

| Model/Spec |

01 H8 |

02 H8 |

P | Q1 | Q2 | Q3 |

R (g7) |

S | T | U | V | W1 | W2 | X1 | X2 | Y1 | Y2 |

| TH428 | 30 | 28 | 101.5 | 11 | 24 | PT1/4 | 32 | 45 | 65 | 88 | 4 | 72 | 105 | - | - | 76 | M4×7 |

| TH536 | 38 | 36 | 119 | 11 | 24 | PT1/4 | 42 | 55 | 80 | 98 | 4 | 80 | 110 | - | - | 83 | M5×10 |

| TH646 | 50 | 46 | 127.5 | 12 | 30 | PT3/8 | 50 | 70 | 95 | 116 | 4 | 98 | 125 | 62 | M4×8 | 98 | M5×10 |

| TH852 | 55 | 52 | 135.5 | 12 | 32 | PT3/8 | 56 | 75 | 100 | 128 | 4 | 100 | 130 | 67 | M4×8 | 110 | M6×10 |

| TH1075 | 80 | 75 | 153.5 | 17 | 36 | PT3/8 | 81 | 100 | 125 | 158 | 5 | 115 | 160 | 92 | M4×8 | 145 | M6×10 |

| TH1291 | 95 | 91 | 165 | 21 | 34 | PT1/2 | 96 | 120 | 142 | 180 | 5 | 136 | 185 | 110 | M4×8 | 165 | M6×10 |

| TH1512 | 125 | 120 | 176.5 | 23 | 40 | PT1/2 | 130 | 160 | 195 | 227 | 6 | 160 | 210 | 171 | M6×10 | 215 | M6×10 |

Performance Parameters

| Model/Spec | Piston area(cm²) |

Stroke (mm) |

Highest turnover nimber min-1 (rpm) |

Max. working pressure Mpa (kgf/cm²) |

Moment of inertia (kg.m²) |

Total volume of oil drainage |

Weight (kg) |

|

| Press side | Pull side | |||||||

| TH428 | 53.2 | 50.5 | 10 | 8000 | 4.0(40) | 0.02 | 3 | 5.8 |

| TH536 | 69.8 | 67.5 | 15 | 8000 | 4.0(40) | 0.05 | 3 | 8.5 |

| TH646 | 97.3 | 87.9 | 15 | 7000 | 4.0(40) | 0.09 | 3 | 13.5 |

| TH852 | 146.8 | 136.6 | 20 | 6200 | 4.0(40) | 0.2 | 3.9 | 16.4 |

| TH1075 | 196.2 | 182 | 25 | 4700 | 4.0(40) | 0.4 | 4.2 | 25.8 |

| TH1291 | 250.6 | 234.1 | 30 | 3800 | 4.0(40) | 0.61 | 4.5 | 33 |

| TH1512 | 345.4 | 334.6 | 30 | 2800 | 4.0(40) | 0.5 | 7 | 50 |

It is recommended to grease chucks at least twice a day in order to maximize longevity

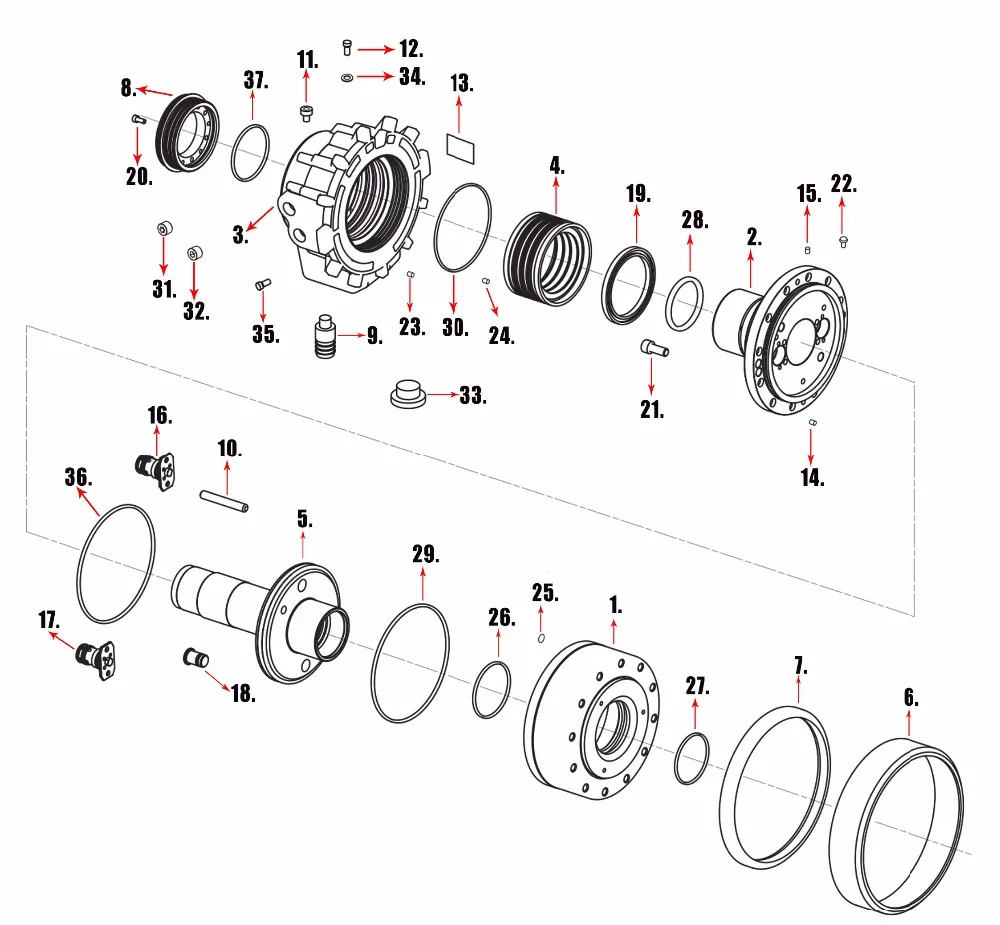

| No. | Name | No. | Name |

| 1 | Body | 20 | Wrench Bolt |

| 2 | Rotation Valve | 21 | Wrench Bolt |

| 3 | Sleeve Body | 22 | Fist Head Cap Screw |

| 4 | Sleeve | 23 | Set Screw |

| 5 | Piston | 24 | Set Screw |

| 6 | Fan cover | 25 | O-Ring |

| 7 | Fan | 26 | O-Ring |

| 8 | Stopper | 27 | O-Ring |

| 9 | Hose Nipple | 28 | O-Ring |

| 10 | Guide Pin | 29 | O-Ring |

| 11 | Air Breather | 30 | O-Ring |

| 12 | Plug | 31 | PT Plug |

| 13 | Name Plate | 32 | PVC Plug |

| 14 | Set Screw | 33 | PVC Plug |

| 15 | Set Screw | 34 | Seal Washer |

| 16 | Lock Valve | 35 | Air Breather |

| 17 | Lock Valve | 36 | O-Ring |

| 18 | Relief Valve | 37 | O-Ring |

| 19 | Bearing |

The matching products including:

1. Fixing Bolt, Hose Nipple.

2. Hydraulic pump unit.

3. Adaptor plate.

cnc lathe machine: lathe chuck, collet chuck, rotary cylinder, hydraulic station, nc turret, live center and other accessories

rotating hydraulic operated lathe chuck oil cylinder rotating hydraulic operated lathe chuck oil cylinder rotating hydraulic operated lathe chuck oil cylinder

-

1000 tons hydraulic press hydraulic cylinder

-

Heavy Duty Dump Truck Hydraulic Cylinder/Double Acting High Quality Telescopic Hydraulic Cylinder, Hydraulic Cylinder, Tie Rod Hydraulic Cylinder

-

pc220 pc240 excavator hydraulic cylinder,707-01-0H680 707-01-0J840 707-01-0J870 707-01-0A350

-

Hydraulic Cylinder Agricultural Machinery Parts Factory Custom HSG Hydraulic Cylinder Double Acting Hydraulic Cylinder

-

China factory steel black length 47.5cm tractor steering hydraulic cylinder MTZ parts 50-3405215

-

Factory custom engineered hydraulic cylinder manufacturer single acting and HSG double acting hydraulic cylinder

-

China electric crane hydraulic cylinder cheap heavy duty 100 tons hydraulic cylinder

-

Conveying machinery with chrome-plated steel rod rod hydraulic cylinder ck45 2jz k24 5.3 forged piston connecting rod shaft

-

10 Ton Hydraulic Scissor Lift Kit for Dump Beds

-

3 Ton Bed Kit Hydraulic Cylinder & Hydraulic Pump Hydraulic Lift Kit

Other Products

-

$285.00 - $2250.00 / set

$285.00 - $2250.00 / set