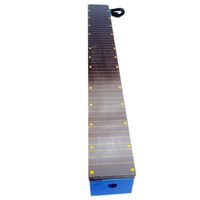

PML2000KG Permanent Magnetic Lifter Manufacturer Lifting Magnets

-

Supplier: Shandong Luci Industrial Technology Co., Ltd. -

Region: Shandong, China -

Contact: Mr Morgan Wang -

Price: $62.50 /set -

Min. Order: 1 set

| Applicable Industries: | Building Material Shops,Machinery Repair Shops,Manufacturing Plant,Retail,Construction works ,Energy & Mining; | Rare Earth Magnet: | Nd-Fe-B Magnet; |

| Package Preview: | ; | Supply Ability: | 200 Set/Sets per Month; |

| Max Breakaway Force: | 17500N; | Place of Origin: | Shandong China; |

| Dimension(L*W*H): | Customised; | Warranty: | 1 YEAR; |

| Rated Lifting Capacity: | 100kg-5000kg; | Handle Length: | 145mm-650mm; |

| Color: | Accept Customized; | Condition: | New; |

| Certification: | ISO9001&CE; | Product Name: | Permanent Magnetic Lifters; |

| After-sales Service Provided: | Online support,Engineers available to service machinery overseas; | Net Weight: | 2kg-280kg; |

| Packaging Detail: | Wooden Case for PML2000KG Permanent Magnetic Lifter Manufacturer Lifting Magnets; | Port: | QINGDAO,TIANJIN; |

| Payment Terms: | T/T; | Brand Name: | LUCI; |

| Size: | Accept Customized; | Usage Mode: | Manual; |

PML2000KG Permanent Magnetic Lifter Manufacturer Lifting Magnets

- Permanent magnetic lifer is made of high performance material ndfeb (Nd - Fe - B) as product kernel .Smaller product volum, stronger hoisting ,permanent magnetism.

Advanced balanced magnetic circuit design,large suction,almost no remanence magnetism,safety.

Max.pulling-out force can reach 3.5times of rated lifting capacity. High safety factor.

- High property ND-Fe-B material,no demagnetization.

- Compact structure easy to operate.

- Work without powder.

Model | Rated Lifting Capacity(KG) | Dimension(mm) | Max Breakaway Force(N) | Net Weight(KG) | |||

| Length | Width | Hight | Handle Length | ||||

| 7YQ100 | 100 | 90 | 63 | 68 | 146 | 350 | 3 |

| YQ400 | 400 | 160 | 95 | 180 | 160 | 1400 | 11 |

| YQ600 | 600 | 220 | 115 | 125 | 230 | 2100 | 22 |

| YQ1000 | 1000 | 260 | 145 | 145 | 280 | 3500 | 40 |

| YQ2000 | 2000 | 340 | 160 | 165 | 410 | 7000 | 60 |

| YQ3000 | 3000 | 420 | 185 | 185 | 510 | 10500 | 90 |

| YQ5000 | 5000 | 580 | 300 | 300 | 650 | 17500 | 400 |

Using high property ND-Fe-B,Changing magnetic force by rotating the handle,achieve retention and release the work-piece. Ring on the top of lifter and V type groove make work easy.

Before lifting, clean up the surface of workpiece first. Make sure the center of magnet chuck and workpiece weight coincide,then turn the crank from “-” to “+” . Check if it’s auto-locked, then crane.

When lifting, overloading is prohibited.No body allowed to pass through under it.The temperature of workpiece and ambient can not over 80degree.without violent vibration and impact.

When lifting round work-piece, keep B chamfer liner contact with the workpiece adjacent angel. So the lifting force will only 30%~50% lifting capacity.

After finish lifting, turn the crank from “+” to “-”.Then the workpiece drop off with the lifting jack.

- Because of different factory custom specifications of products,product size and shape are different,so product appearance depends on goods

- Because of different type and specification,market prices fluctuate frequently,so the actual price will be subject to the contract

- Our company has many kinds of electric permanent magnetic chucks, different targets, please reference selection guidelines before selection.First determine the use of workpiece and use function,then choose different categories of products.Electric permanent magnetic chuck is suitable for all kinds of large quantities of assembly line work.

- More info. please contact Luci of the personnel of the service,ask about details,provide your demand, professional engineers will make plan for you.

-

Fixed overhead magnet lifting magnet 220V magnetic lift 1 ton 2 ton 5 ton lifting magnet

-

Over 10 years of heavy duty metal scrap lifting magnets for steel plate permanent magnet lifters

-

Magnetics Inc Mate Manhole Cover Lifter Manhole Cover Lifter OEM Manhole Cover Lifter

-

Safety 2000kg Permanent Magnet Lifter Solenoid

-

CE Approved Custom Lifting Magnets 600kg Pulling Force

-

2 ton 2000kg PML permanent magnetic lifter / lifting magnet for lifting steel plate

-

Small powerful electromagnet, electromagnetic lifting device, battery electric permanent magnet lifting magnet

-

Suction 2.5kg Solenoid Mini Electromagnet 25n 12v Electromagnet 12 Volt Small Electro Magnet 24v Coil 6v Electric Magnet

-

Hot Sale 1000kg 1.5m 24V Round Magnetic Scrap Lifting Magnet Electromagnet For Scrap Iron Steel Scrap On Cranes And Excavators

-

New design magnetic manhole cover lifter

Other Products

-

$300.00 / set

$300.00 / set -

$3280.00 / set

$3280.00 / set -

$2400.00 / set

$2400.00 / set