custom Die Casting aluminum Y112 valve caps

-

Supplier: Stone Industrial Co., Ltd. -

Region: Sichuan, China -

Contact: Ms Tong Xiaojia -

Price: $4.90 / >=100 pieces -

Min. Order: 100 pieces

| Port: | Ningbo, Shanghai; | Payment Terms: | L/C,T/T; |

| Place of Origin: | Sichuan China; | Surface Treatment: | Shot blasting; |

| Certification: | ISO9001, IATF 16949; | Type: | Valve Cap 2; |

| Model Number: | OEM; | Application: | Valves; |

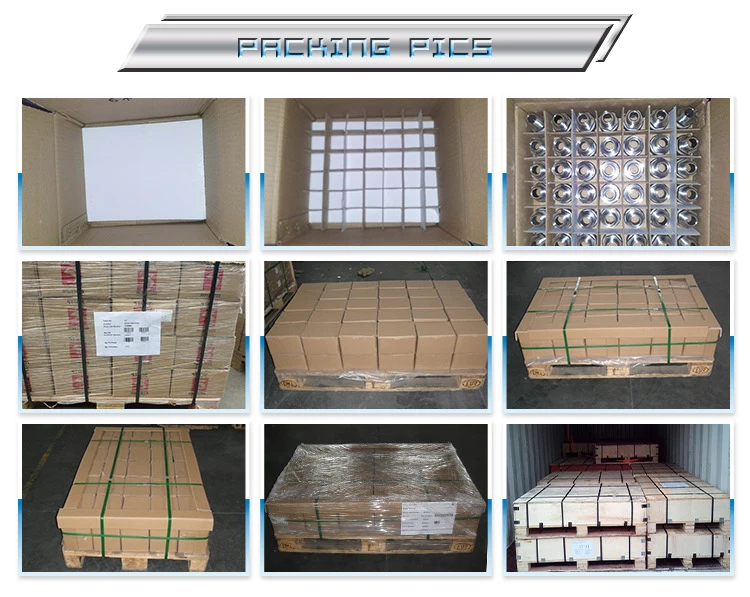

| Packaging Detail: | Standard export packages (carton/ply-wood case/pallet) / Customized; | Product name: | custom Die Casting aluminum Y112 valve caps; |

| Material: | Aluminum Y112; | Tolerance: | Casting: ISO 8062 DCTG 4 Machining: 0.01mm; |

| Supply Ability: | 1000000 Piece/Pieces per Month; | Drawing formation: | PDF, IGS,STP,DWG; |

| Brand Name: | OEM; | Process: | Die Casting; |

custom Die Casting aluminum Y112 valve caps

Verified supplier certified by international authoritative certification organization, product quality guarantee and company strength guarantee.

Welcome to visit our factory anytime.

Our advantage

1.Over 20years of international experience in the field of mechanical manufacturing.

2.OEM and ODM.

3.Over 5years of experience working with Moody.

4.Overseas subsidiaries in Dallas, USA and Aachen, Germany with warehouses.

5.Automatic production line to meet precision and high efficient modern production.

6.PED / ISO9001 / IATF16949 certified by TÜV Rheinland.

Provide forging,casting,machining process services,according to your needs or your drawings,produce the products you need.

Own factory and technical team, reliable quality, cheap price. Learn more 30%off

Capability for Die Casting & CNC Machining

Aluminum Alloy | ENAC-44300, ENAC-46100, A360, A380, ADC1, ADC1C, ADC2, ADC3, ADC5, ADC6, ADC12, etc. |

Zinc Alloy | GD-ZnAl4, GD-ZnAl4Cu1, ZP0400, AG40A, ZA-8, Z35530, Z33520, ZCDC1, ZCDC2, Zamak2, Zamak3, Zamak5, etc. |

Casting Weight Range | 8gram – 30kgs |

Casting Diameter Range | 1mm – 850mm |

Casting Tolerance | ISO 8062 DCTG4 |

Casting Surface Roughness | Ra 6.3 |

Machining Tolerance | 0.01mm |

Machining Surface Roughness | Ra 0.6 |

Heat Treatment | T1, T2, T4, T5, T6, T7, etc. |

Surface Treatment | Vacuum Impregnation,Sand-blasting, Shot-blasting, Vibration grinding, Zinc-plating, Nickle-plating, Coating, Painting, Electrophoresis, Black phosphating, etc. |

Special Inspection | Leakage test, Shell Strength test, Radiographic test, Salt spray test, etc. |

Quality Documents | Measuring report, Material certificate, PPAP, APQP, FMEA, etc. |

Real factory, each process is strictly controlled.

Real factory, each process is strictly controlled.

Quality is strictly controlled and absolutely guaranteed;Measuring report, EN 10204 3.1 material certificate, PPAP, APQP, FMEA, etc.

Quality is strictly controlled and absolutely guaranteed;Measuring report, EN 10204 3.1 material certificate, PPAP, APQP, FMEA, etc.

Provide forging,casting,machining process services,according to your needs or your drawings,produce the products you need.

Provide forging,casting,machining process services,according to your needs or your drawings,produce the products you need.

Long-term cooperation with world-renowned companies, absolute quality assurance, and strength assurance.

Long-term cooperation with world-renowned companies, absolute quality assurance, and strength assurance.  Frequently participate in various well-known exhibitions in china and abroad, such as the United States, Britain, Germany, covering Africa, Asia, Europe, etc. You can leave your contact information so that we can invite you to visit our exhibition on-site when we hold exhibitions abroad or in china.

Frequently participate in various well-known exhibitions in china and abroad, such as the United States, Britain, Germany, covering Africa, Asia, Europe, etc. You can leave your contact information so that we can invite you to visit our exhibition on-site when we hold exhibitions abroad or in china.

We have PED, ISO9001,ISO/TS16949,IATF16949 certification.

We have PED, ISO9001,ISO/TS16949,IATF16949 certification.

We have our own factory and technical team with hundreds of senior engineers who have been in this industry for at least 20 years.

Welcome to visit our factory for more information.

Packaging method can be customized.

Packaging method can be customized.

1.Is your company a manufacturer?

Yes, we Stone group have 4 factories.

2.How about your export experience?

80% exported to Western Europe and North America, for customers like Siemens, Geberit, KSB, etc.

3 .What does your company need to submit a quotation?

Drawings or Samples, together with information like quantity, material, tolerance etc.

4 . What if we do not have a drawing?

We can build the drawing according to your samples and offer you the price.

5. How soon before I get a sample?

8 weeks for tools and samples for OEM parts, 3-7 days for express.

-

OEM specializes in the production of high-fin short nostalgic smooth aluminum cast valve covers

-

Slotted Head Stem Cap Spool Removal Tool Service Valve Brass Flared Cap for 1/4" HVAC Threaded Cap Brass Cap

-

Universal wheel valve cap black plastic tire valve cap

-

10pcs R134a Dust Cover 13mm Blue Low Side 16mm Red High Side Air Conditioner Cover for R134a AC System

-

China Market QF-2G1 Oxygen/Nitrogen/Air Brass Cylinder Valve

-

Hot Sale Custom Color Red Pink Yellow Gold Disc Tire Dust Valve Stem Cover

-

90 Pack of 18 Car R134a / R12 Air Conditioning Valve Covers for Air Conditioning Service AC System

-

Hot Sale 4 Colors Firefly LED Wheel Lights for Cars, Motorcycles with Batteries

-

Factory Manufacturer Professional Quality Best Selling Low Price UMETASS Wholesale IBC Water Tank Screw Cap with Vent Cap

-

China factory anti-theft lock tire valve cover

Other Products

-

$3.60 / piece

$3.60 / piece