Foam Production Line Continuous Pre-expander Expandable Polystyrene EPS Foam Machine Price

-

Supplier: Hangzhou Epsole Technologies Co., Ltd. -

Region: Zhejiang, China -

Contact: Mr Ricky Wu -

Price: $8000.00 /set -

Min. Order: 1 set

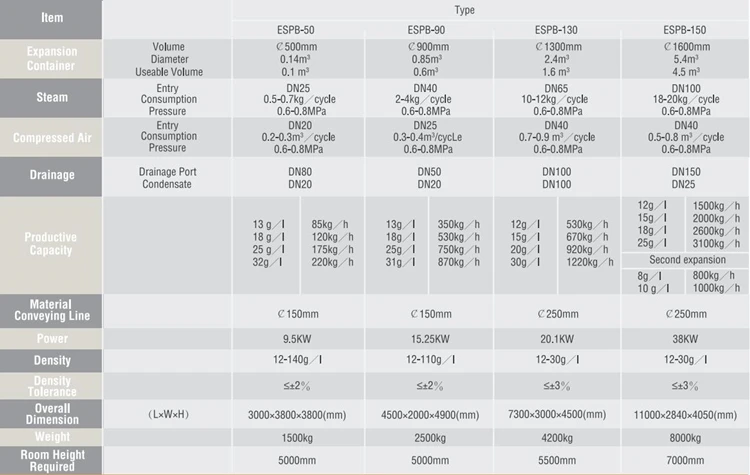

| Showroom Location: | None; | Processing Type: | Foaming Machine; |

| Density Tolerance: | ≤±2%-3%; | Power (kW): | 7.5; |

| Port: | Shanghai,Ningbo; | Local Service Location: | None; |

| Payment Terms: | L/C,T/T; | Size: | 4700(4905)x2660(4655)x2600(3250)mm; |

| Packaging Detail: | bulk; | Voltage: | 220-415V; |

| Warranty: | 1 year; | Supply Ability: | 150 Set/Sets per Year; |

| Dimension(L*W*H): | 4700)x2660x2600; | Brand Name: | Epsole; |

| Power(W): | 8.93-13.33kw; | After-sales Service Provided: | Engineers available to service machinery overseas; |

| 2nd Expansion Foam Density: | 8-11(13)/1; | Key Selling Points: | Automatic; |

| Material: | Steel; | Applicable Industries: | Construction works ; |

| Condition: | New; | Machine Type: | NEW; |

| Weight (KG): | 7500 KG; | Room Height Required: | 3000mm; |

| Feeding Pipe: | 150mm-250mm; | Place of Origin: | Zhejiang China; |

| 1st Expansion Foam Density: | 12(14)-30g/l; | After Warranty Service: | Video technical support,Online support; |

| Certification: | CE; | Product Type: | Continuous EPS Pre-expander; |

| Processing Type: | Foaming Machine; | After-sales Service Provided: | Video technical support,Online support; |

![]()

![]()

![]()

Pre-expander is an essential machine for producing EPS products. The machine is for preexpanding

polystyrene beads with expansion agent. Expanded beads through aging under normal pressure can be

used to produce all kinds of package products and blocks. EPS package products are suitable for packing

household appliance, instruments, gauges, chinaware, glassware and all valuable and crisp products.

EPS blocks are used for construction, heat insulation of car, ship and cooling house. EPS is good material

for heat insulation, sound insulation and vibration proof.

Function & Features:

--All process works automatically including filling, expanding, sieving, grinding and conveying, etc.

--With twice pre-expansion function, foam density could be 8-30 g/l.

--Frequency conversion feeding equipment

--Power-off protection device

--Japanese relief valve

Continous Pre-Expander

Batch Pre-Expander

-

High Pressure Polyurethane Foam Injection Machine Polyurea Spraying Machine

-

High Viscosity Pneumatic Oil Pump Grease Barrel Pump Air Barrel Pump

-

Outdoor party event hot sale snow foam daddy super re maquina de espuma foam machine

-

Q2600 Polyurethane Foam Sprayer

-

Portable Polyurethane Sprayer Foaming Machine

-

Automatic Control EPS Foam Vertical Cutting Machine

-

Closed cell polyurethane foam insulation machine FD-E10H

-

Closed cell polyurethane thermal foam insulation machine spraying machine pu foam spraying machine

-

Sponge cutter for kitchen cleaning

-

MDI Rigid Polyol Isocyanate Polyurethane Foam Insulation Spray From China Factory!