Continuous Glass Sheet Vacuum Aluminium Coating Mirrors Making Machine

-

Supplier: Xiangtan Hongfeng Mechanical Equipment Manufactory -

Region: Hunan, China -

Contact: Ms Jane Liu -

Price: $876543.00 /set -

Min. Order: 1 set

| Glass thickness: | 3-25mm; | Equipment Name: | Continuous Glass Sheet Vacuum Aluminium Coating Mirrors Making Machine; |

| Power(W): | 975Kw; | Machine Type: | Glass Coating Machine; |

| Condition: | New; | Supply Ability: | 5 Set/Sets per Year for Vacuum Aluminium Coating Mirrors Making Machine; |

| Weight: | About 150 tons; | HS Code: | 8543300090; |

| Packaging Detail: | 1. When the machine is shipped, it is in un-assemble condition. 2.. Solid steel with polywood plates of boxes, the inside boxes, the machine is carefully protected by the plastic rolling film from moisture and dust. The packing can make sure you will receive a machine without any destroy. 3. We need a full container for Continuous Glass Sheet Vacuum Aluminium Coating Mirrors Making Machine 4. The package can be made according to client's order; | Dimension(L*W*H): | 45*4*3m; |

| Voltage: | 380V; | Material: | AL, CR, AG; |

| Type: | Horizontal; | Production Capacity: | 100%; |

| Application: | Architectures Furniture Household Appliance; | Size: | Custom made; |

| Certification: | CE; | Brand Name: | Hongfeng PVD Machines; |

| Control system: | PLC(Mitsubishi); | Warranty: | 1 Year warranty; |

| Work mode: | Full automatic; | Payment Terms: | L/C,D/A,D/P,T/T,Western Union,MoneyGram; |

| After-sales Service Provided: | Online support,Field installation, commissioning and training,Field maintenance and repair service,Video technical support; | Place of Origin: | Hunan China (Mainland); |

| Port: | Shanghai, Ningbo, Guangzhou, Shenzhen, Qingdao or under customer's order; |

Continuous Glass Sheet Vacuum Aluminium Coating Mirrors Making Machine

This equipment can produce a kind of coated glass products, which has a function of sunshade, insulation, energy conservation and decoration, by the use of cylindrical magnetron sputtering target technology and high-precision power supply in flat glass. By adjusting the size of current, gas flow, the speed of target movement, you can get different products with different transmission layer, which are mainly used for the decoration of large-scale construction curtain walls and balconies.

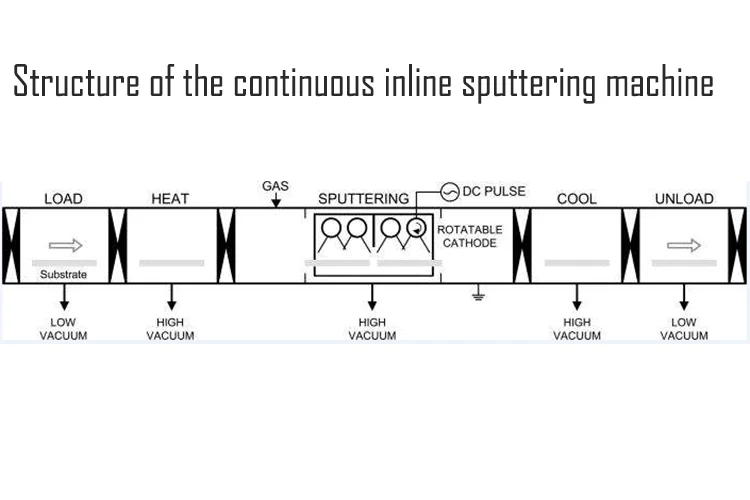

Structure of the magnetron sputtering coating line

The vacuum coating production line is usually connected by more than three vacuum chambers to form a continuous working vacuum coating machine.

- Advantages of this vacuum coating line are:

- Extremely high vacuum, high film quality

- Coating film quality is stable

- High productivity

- High degree of automation, fewer operator requirements

Vertical magnetron sputtering coating line(Custom made)

Hongfeng VAC uses advanced magnetron sputtering coating technology in Europe and America, combined with the actual situation, the development of innovation and introduction of high-grade aluminum mirror coating production line, allowing users to comprehensively improve the competitiveness of many in the variety, quality, efficiency, scale, high technology, and automation. The line is equipped with PLC and touch screen or industrial computer to achieve automatic control, to provide customers with high-quality low -cost products.

Horizontal Magnetron Sputtering Coating Production Line(Custom made)

The company can provide design according to user requirements, provide a full set of equipment, responsible for the process, according to "turnkey" engineering services.

Samples of glass mirrors

Accorinf to different technical requirements of each customers, we can design different types of magnetron sputtering cathodes for the machine. This is the coating system of the machine. You can load different raw material to the cathodes for different coatings.

Technical Spcifications

| Chamber type | Vertical and horizontal method of multi-chamber | |

| Applied material | Glass and Wafer, other plastic, metal materials | |

| Substrate size | Vertical type | According to the size of customer's glass sheet |

| Horizontal type | According to the size of customer's glass sheet | |

| Tact time | 120 sec or less (Static method) 90 sec or less (Dynamic method) | |

| Coating source | Sputter source | Rotary cathode, Planar cathode |

| Coating material | Metal material | Al, Ti, Cr, Cu, NiCr, Ni, Ag, other metal material |

| Reactive material | TiO2, Nb2O5, SiO2, TIO, SiAlOx, MoOx, other nitride / oxide material | |

| Power supply | DC, Pulse DC, MF | |

| Thickness uniformity | ±10% or less (Static film) ±5% or less (Moving film) | |

| Measuring instrument | Sheet resistance, optic (Transmittance, reflectance, color-difference meter), | |

| plasma emission monitor, RGA | ||

| Household appliances field | Decorative coating on household products and exterior of mobile devices | |

| Energy field | Silver & aluminum mirror manufacturing industry | |

Customers cases

Customers visiting

Quality is our Culture

1.Professional &advanced PVD vacuum coating machine manufacturer with 10 years working experience.

2.Turnkey vacuum system projects solutions

3.OEM,ODM is welcome.

4.Professional engineers available to go abroad for the installation and training.

5.CE/ISO9001 Certification.

6.Fully capable for vacuum deposition on all kinds of material

7.Professional sale and PVD coating system design teams for personal tailor service

8.Complete quality control and management system

9.Up to 15 months years warranty

10. One-stop-shop service with PVD machines

Our Services

1. Free consultation service before, during, and after sales;

2. Free project planning and design services;

3. Free debugging of equipment until everything is functional;

4. Free long distance shipping management from seller's factory to named place by buyer;

5. Free maintenance and operating training personally;

6. Provide 1 year complete warranty and life-time maintenance service;

7. Vacuum coating service needs introduce for our clients

Our Certifications

Learn more about us, welcome to click: https://hongfengjixie.en.alibaba.com

Mechanical Processing Details

FOR MORE APPLICATIONS, PLEASE TALK TO US!

-

2436 Full Convection Flat Glass Tempering Furnace

-

aluminum cutting machine for window making aluminum cutting for door and window making machine

-

Portable Glass Edger

-

Glass Air Table

-

Glass Air Cushion Table

-

China fast light glass edging machine

-

Portable glass beveling edge grinding edge processing machinery linear glass mirror edge polishing machine

-

CE energy saving fused glass machine price

-

Turnkey project of frit glass melting furnace production line

-

Glass Processing Equipment Linear Glass Bevel Polishing Machine

Other Products

-

$22000.00 / set

$22000.00 / set -

$50000.00 / set

$50000.00 / set -

$55000.00 / set

$55000.00 / set