Sheet Metal Fabrication Flat Metal Shelf Brackets for Bunk Bed

-

Supplier: Yantai Yogy Precision Metal Products Co., Ltd. -

Region: Shandong, China -

Contact: Mr Tom Liu -

Price: $2.00 /piece -

Min. Order: 1 piece

| business type: | sheet metal fabricator; | Structure: | Triangle Bracket; |

| process 4: | QC and packing; | Port: | Qingdao; |

| precision: | +/-0.1mm; | Payment Terms: | L/C,D/P,T/T; |

| Brand Name: | YGM; | process 1: | fix the burr; |

| certificate available: | CE, SGS, normal customs clearance documents; | warranty: | we borne 100% responsibility for quality problem; |

| Model Number: | OEM; | Standard or Nonstandard: | Nonstandard; |

| Supply Ability: | 120 Ton/Tons per Month Sheet Metal Fabrication Flat Metal Shelf Brackets for Bunk Bed; | OEM experiences: | 12 years; |

| process 2: | Laser cutting; | process 3: | surface treatment zinc plating, anodizing, chrome plate; |

| Packaging Detail: | metal bracket packing: Method 1: Shrink film, then bulk loading Method 2: Shrink film + box + pallet/ wooden case Method 3: PP + wooden case Method 4: As per customers' requirements or negotiated Packing sizes decided by product sizes; | Place of Origin: | Shandong China; |

| Product name: | Sheet Metal Fabrication Flat Metal Shelf Brackets for Bunk Bed; |

Sheet Metal Fabrication Flat Metal Shelf Brackets for Bunk Bed

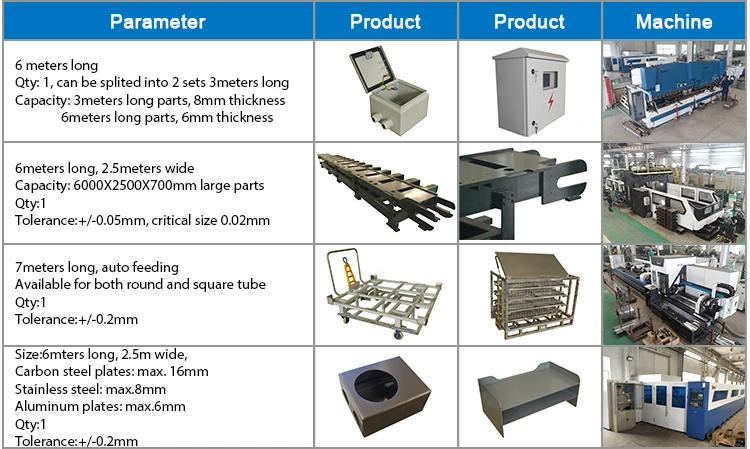

Service | CNC Machining |

Sheet Metal Fabrication | |

Control Box | |

Laser Cutting Service | |

Steel Bracket | |

Stamping Parts | |

Material | *Aluminum |

*Steel,Stainless Steel | |

*Copper,Brass | |

*Plastic | |

*Die Casting | |

Finish | Sandblasting, Anodizing Color, Blackenning, Zinc\Nickl Plating, Polishing And Brushing,Etc. |

Main Equipment | CNC Machining Center(Milling), CNC Lathe, Griantry CNC Machining Center,Etc. |

Cylindrical Grinder Machine, Drilling Machine, Laser Cutting Machine,Etc. | |

Tube Laser Cutting Machine,Flame Cutting Machine,Robert Welding Arm,Etc. | |

Bending Machine,Stamping Machine,Sand Blasting Machine,Powder Coating Line | |

Drawing Format | Step,Stp,Gis,Cad,Pdf,Dwg,Dxf Etc Or Samples. |

Delivery Time | 5-30Days Depends On Quantities |

QC | ROSH, CE, ISO |

Tolerance | +/-0.02mm ~ +/-0.05mm |

Surface Roughness | Ra 0.6-3.2 |

Method 1: Shrink film, then bulk loading

Method 2: Shrink film + box + pallet/ wooden case

Method 3: PP + wooden case

Method 4: As per customers' requirements or negotiated

-

Galvanized hardware decorative furniture corner glue corner braces

-

Wholesale Metal Angle Plate Extruded L Shape 4040 4080 4 Hole Corner Bracket Connector

-

Multifunctional woodworking bracket

-

External connecting plate T aluminum 5-hole L-shaped connecting plate angle bracket plate suitable for 2020 aluminum profiles

-

4x4 6x6 8x8 Wood Post Base Pergola Wood Bracket Kit with Steel Brackets Pergola Boot Shoulder Brackets

-

Furniture Parts Metal Processing Custom Pergola Corner Bracket Good Quality

-

Wood Frame Construction Storage Shed Hill Top Roof Storage Shed Garage Barn DIY Frame Kit

-

Zuogang Wholesale Furniture Hardware Custom Floating Stainless Steel L Angle Bracket Mount Folding Shelf Wall Bracket

-

Air Conditioner Bracket Wall Mounting Bracket for Outdoor Bracket Air Conditioner with Screws Manual Winch and Installation Tool Kit

-

4x4 6x6 Pergola Brackets Carbon Steel Brackets Arches Metal Pergola Post Kit

Other Products

-

$20.00 / piece

$20.00 / piece -

$20.00 / piece

$20.00 / piece -

$20.00 / piece

$20.00 / piece -

$35.00 / piece

$35.00 / piece