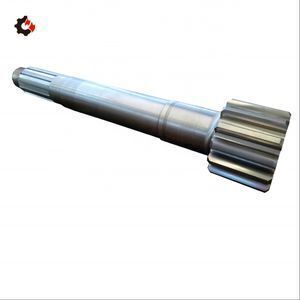

Dragline Excavator Custom AISI 1020 Large Module Forged Transmission Parts Bull Spur Gear Shaft

-

Supplier: Luoyang Wangli Heavy Machinery Co., Ltd. -

Region: Henan, China -

Contact: Mr Wonderly Wang -

Price: $50.00 /piece -

Min. Order: 1 piece

| Product Name: | Forged Excavator Transmission Parts AISI 1020 Bull Spur Gear Shaft; | Surface Treatment: | Surface Hardening or Carburizing and Quenching; |

| Material: | AISI1045,4340,4140,34CrNiMo6; | Place of Origin: | Henan China; |

| Port: | TIANJIN,QINGDAO or Others; | Structure: | Gear; |

| Certificate: | BV,SGS,ISO 9001:2008; | Applicable Industries: | Manufacturing Plant,Energy & Mining; |

| Payment Terms: | L/C,T/T; | OD For Gear Wheel: | MAX.13 000 mm; |

| Module of Gear: | 8-120; | Gear Machining: | Gear milling; |

| Supply Ability: | 9000 Ton/Tons per Year; | Brand Name: | LUOZHONG; |

| Height For Gear Wheel: | MAX. 1200 mm; | Heat treatment: | QT; |

| Torque Capacity: | N/A; | Packaging Detail: | Package for Dragline Excavator Custom AISI 1020 Large Module Forged Transmission Parts Bull Spur Gear Shaft is wooden box and adapts to ocean transport; |

| Forging or Casting: | Casting; | Tolerance: | +/-0.01; |

| Coatings: | Oil; | Model Number: | OEM; |

--OEM Machinery Parts Supplier

Over 30 years experiance in manufacturing OEM machinery parts and non standard machinery Parts according to engineer drawings.

--Technical Supports for Material

Technical supports for new material and new manufacturing process according to customers working conditions in order to improve lifespan of machinery parts.

--Military Quality

Participating in the designing and manufacturing rail for the largest radio telescope in Asia and forging dies for the airplane for the military industry.

Produce Name:

Large Module Forged Custom Dragline Excavator Transmission Parts AISI 1020 Bull Spur Gear Shaft

Heat Treatment--quenching and tempering to guarantee the total hardness.

We can produce precision steel forging long spur gear shaft,helical gear shaft,herringbone gear shaft.

Except gear shaft,we are also specialized on producing other dragline excavator spare parts,such as large module forging and casting gears,rope sheave,rail,gear rack,track link,etc.

Forging Double Helical Gear Shaft

Spur Gear Assembly

UT Or MT.

Size Inspection

Strictly size inspection control during every production process and make a record.

Mechanical Property Testing

--Luoyang Wangli Heavy Machinery Co., LTD is mainly engaged in the designing and manufacturing of large machinery components and non-standard machinery parts.

--Our products are mainly used in the fields of mining machinery, petroleum machinery,cement plant,steel mill, power plant, sugar factory etc,including shafts, gears, sprockets, sheaves, couplings,support rollers, large bearing housing and other large forging and casting parts.

--After over 20 years of development,various large non-standard machinery products have been already sold to the whole China and exported to 32 countries including the United States, Russia, Germany, Spain,India,etc.

Product Parameter

Forging

Ring Rolling Machine

5 meters ring rolling machine

Casting

Vertical Lathe

Horizontal Lathe

CNC Machining

Gear Hobbing

Gear Hobbing

After over 20 years of development,various large non-standard machinery products have been already sold to the whole China and exported to 32 countries including the United States, Russia, Germany, Spain,India,etc.

-

Precision CNC turning machining of metal parts Linear shaft Stainless steel shaft

-

Expanding Parts Expandable Air Shaft Adapter

-

Flexible shaft 15

-

small industrial universal joint shaft assembly black 18*47 jointed shaft

-

Precision CNC Grinding CNC Machining Axis Parts Milling Spindle Machining Milling Axis CNC Turning Axis

-

Factory supply stainless steel processing shaft mechanical parts CNC turning drive shaft turning shaft

-

Airshaft Air Shaft Mechanical Manipulator Air Shaft

-

Rubber bladder bladder rubber tube for air shaft and air adapter

-

Steel flexible shaft inner core

-

Chuck Inflator Extension Hose Practical and Customizable Shaft Inflator

Other Products

-

$1.00 / kilogram

$1.00 / kilogram -

$1.00 / kilogram

$1.00 / kilogram